Inverted-U-shaped-tube differential pressure gauge

A U-shaped tube and differential pressure gauge technology, applied in the field of differential pressure gauges, can solve the problems of poor accuracy, pressure gauge reference error, large error, etc., and achieve the effects of convenient installation and use, increased pressure resistance value, and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

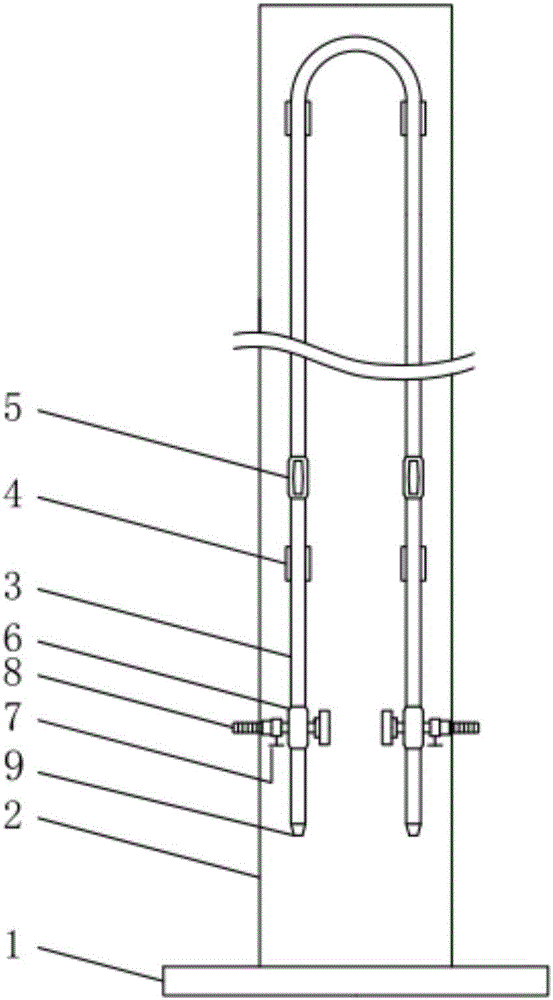

[0024] Such as figure 1 As shown, the present invention includes a base 1 and a bracket 2, the bracket 2 is installed on the base 1, and an inverted U-shaped tube 3 is arranged on the bracket 2; Both sides of the U-shaped pipe 3 are symmetrically provided with a stop valve 5, and a three-way valve 6 is installed below the stop valve 5; one branch of the three-way valve 6 is connected with the inverted U-shaped pipe 3, and the other two branches are connected with the discharge port 8 respectively. It is connected with the test interface 9; the ball valve 7 is installed at the discharge port 8, and the net plug is installed at the test interface 9; the scale is set on the bracket 2; the inverted U-shaped tube 3 is made of plexiglass.

[0025] The inverted U-shaped tube 3 of the present invention uses plexiglass to replace the original glass, its pressure resistance is greatly improved, and it is suitable for testing in high-pressure environments. The bracket 2 is in the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com