Monitor lens positioning assembly

A technology of lens positioning and monitoring, applied in the direction of instruments, optical components, installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

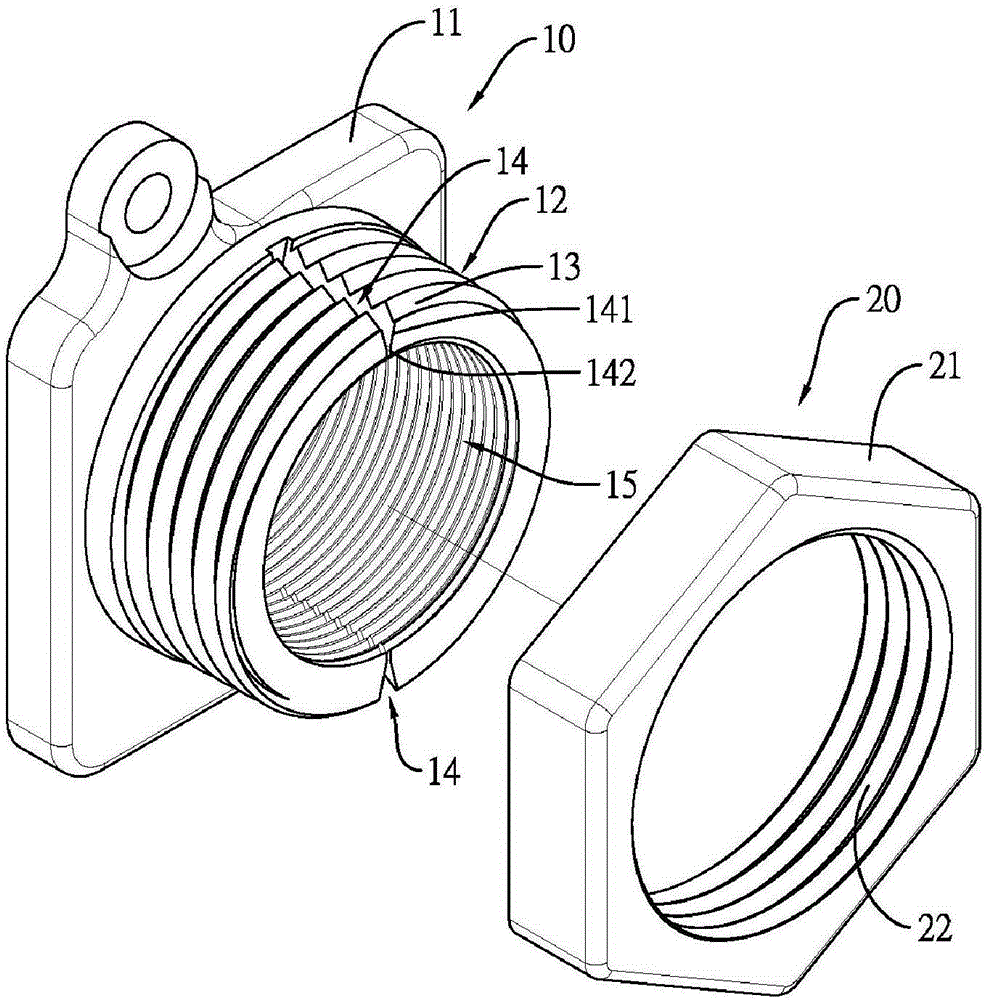

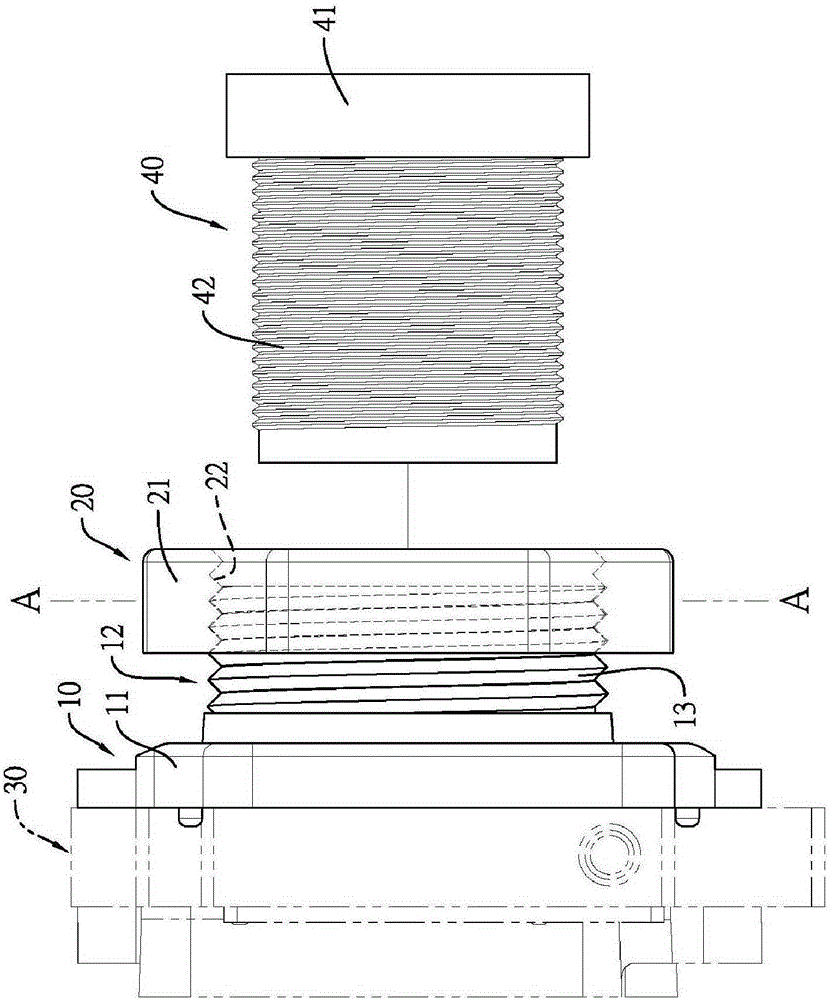

[0046] The monitor lens positioning assembly of the present invention mainly includes a positioning sleeve and a locking piece. Figure 1 to Figure 6 where is the first type of positioning component, Figure 7 Then it is the second type of positioning component.

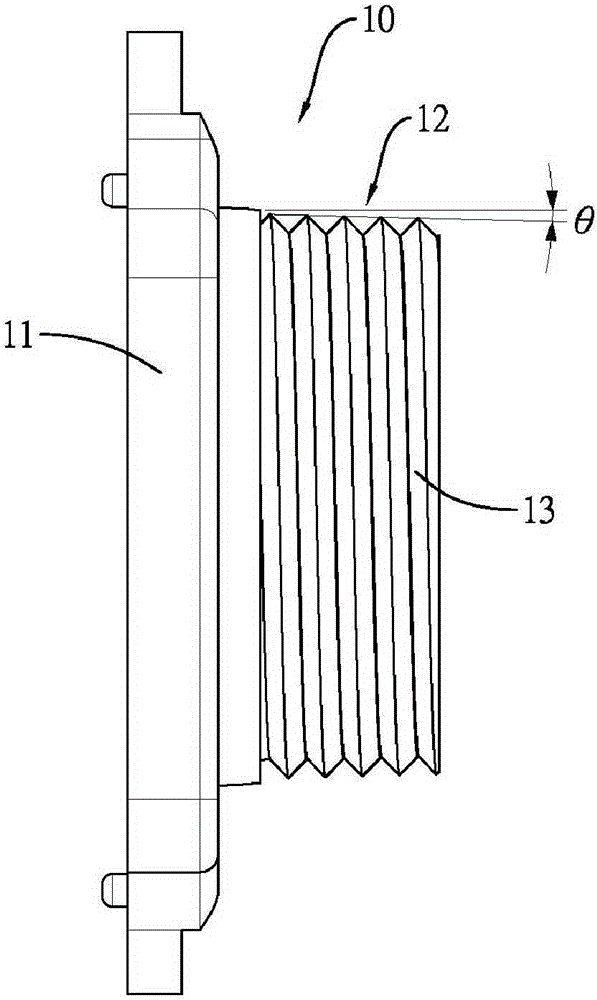

[0047] Please see first figure 1 As shown, the monitor lens positioning assembly of the present invention includes a positioning sleeve 10 and a locking member 20, wherein the positioning sleeve 10 has a connecting portion 11 fixed with the monitor main equipment, through the connecting portion 11 and the monitor main equipment Combination relationship, so that the positioning sleeve 10 is located at the front end of the monitor main equipment, and the front end of the connecting part 11 extends a sleeve part 12. The sleeve part 12 is in the shape of a conical rod. Please refer to figure 2 As shown, there is an inclination angle of θ, so that the diameter of the sleeve portion 12 adjacent to the connecting portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com