Gravity induction counter system

A technology of gravity sensing and gravity sensor, applied in data processing applications, instruments, logistics, etc., can solve problems such as counting errors, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

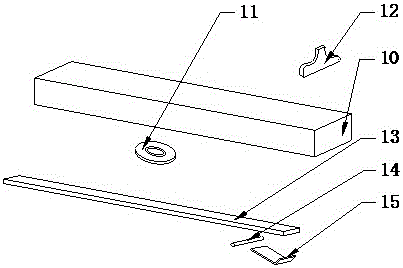

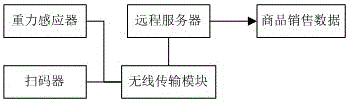

[0048] Embodiment one, such as figure 2 As shown, the wireless transmission module sends the weight information of the gravity sensor 11 to the remote server in real time, and the remote server also includes a sales analysis module, which records the quantity of commodities obtained by the calculation module, and according to the reduction of the quantity of commodities Obtain commodity sales data, if the remote server learns that the weight of commodity A is 10g according to the commodity information obtained by the scanner 12, and learns that the total weight of commodity A on the product grid is 100g according to the weight information, then it can be known that the quantity of commodity A is 10 pieces , when the weight information is 90g, it can be known that product A has sold 1 piece, and according to the reduction of the container from 100g to 50g within the operating time, it can be known that product A has sold 5 pieces within the operating time.

Embodiment 2

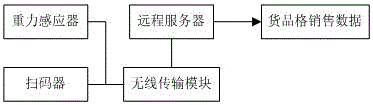

[0049] Embodiment two, such as image 3 As shown, the wireless transmission module sends the weight information of the gravity sensor 11 to the remote server in real time, and the remote server also includes a sales analysis module, which records the quantity of commodities obtained by the calculation module, and according to the reduction of the quantity of commodities Corresponding to the position information of the product, the sales data of the product is obtained. For example, the remote server learns that the weight of the first product is 10g according to the product information and location information obtained by the scanner 12, and the total weight of the first product on the A1 product is obtained according to the weight information. 100g, it can be known that the quantity of product A is 10 pieces. When the weight information is 90g, it can be known that product A has sold 1 piece. According to the reduction of A1 product quality from 100g to 50g within the operatin...

Embodiment 3

[0050] Embodiment 3, the remote server also includes a sorting module and a purchase suggestion module, the sorting module sorts the product sales data and the product category sales data to obtain the commodity names and product category location names arranged in sequence, and the purchase suggestion module sorts the sequentially arranged Commodity names correspond to the product cell position names arranged in sequence to obtain the recommended placement product cell data of hot-selling products. For example, the product names are sorted as A, B, C, and D, and the product cell position names are sorted as A1, B1, C1, and D1. It is suggested that product A be placed in A1, product B in B1, C in C1, and D in D1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com