Semiconductor heat treatment equipment processing gate state detection device and detection method

A technology of heat treatment equipment and detection devices, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc. It can solve the problems of time-consuming installation and adjustment, difficulty in leveling the process door, and inconvenient real-time observation, etc., and achieve economical leveling Time, the effect of avoiding leveling errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

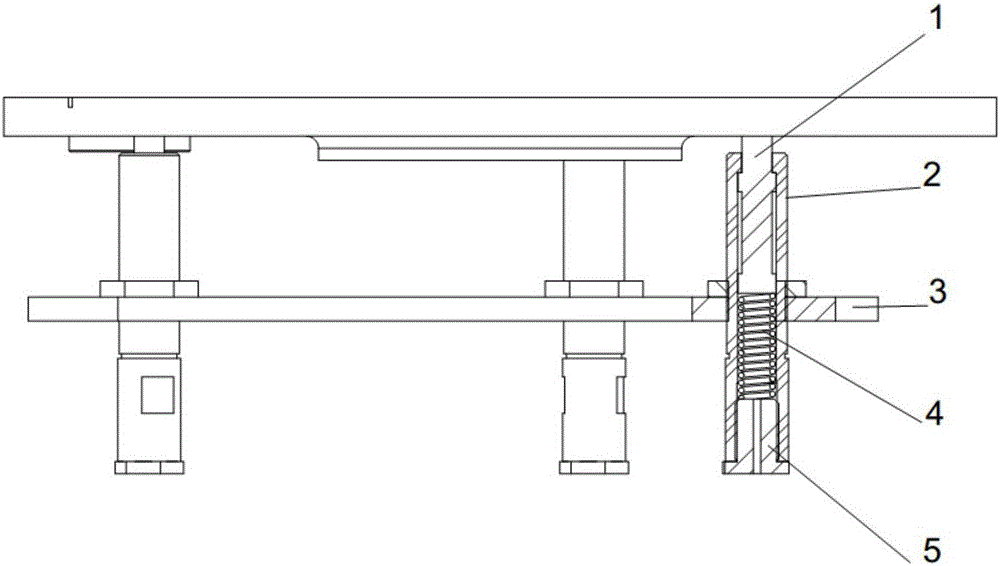

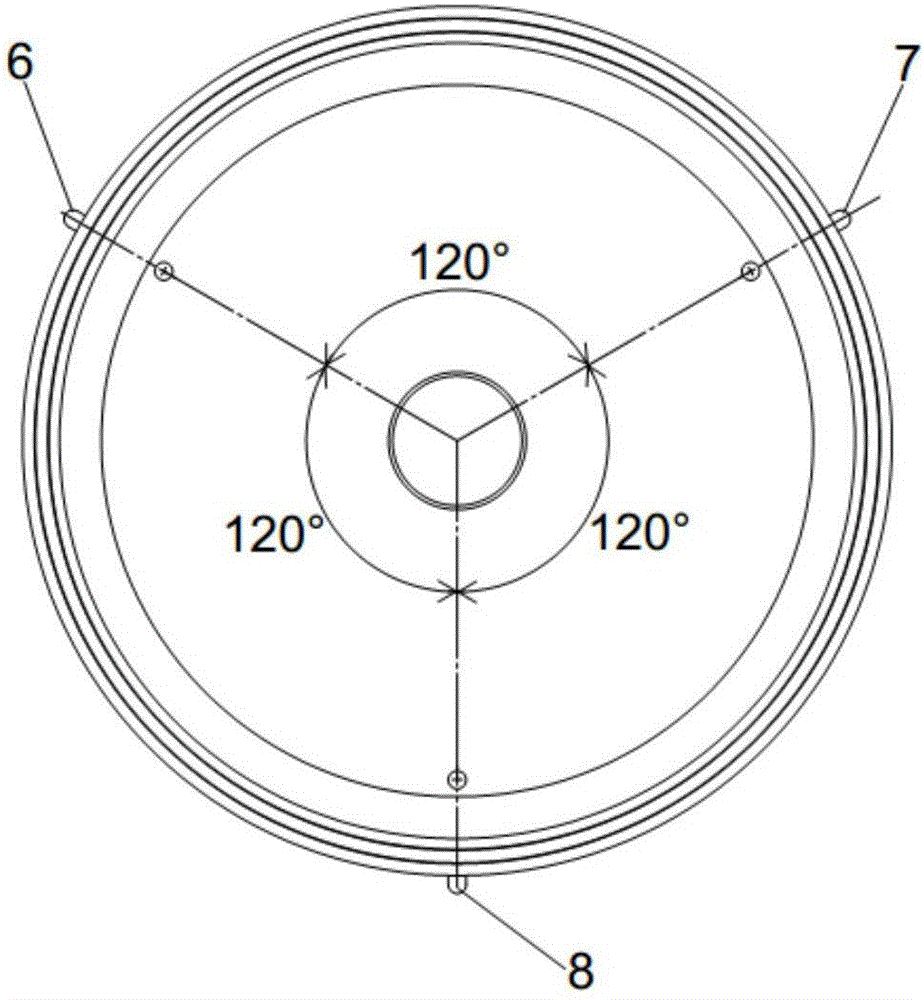

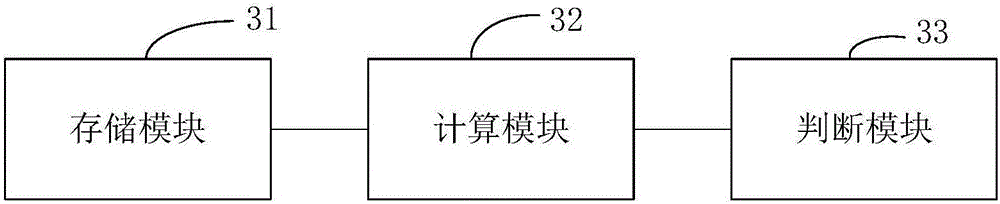

[0031] figure 2 It is a top view of the upper distance measuring sensor of the process door and the detection device according to an embodiment of the present invention. In the present invention, the lower end surface of the process door is connected with the support plate through the supporting structure, so that when the lifting device drives the support plate to lift, the process door also lifts and lowers with the support plate. The detection device of this embodiment includes at least three upper ranging sensors and a detection unit. See figure 2 The upper distance measuring sensor is arranged on the craft door. Specifically, the three upper distance measuring sensors 6, 7, 8 are distributed along the circumferential direction of the craft door on the side of the craft door, and are located at the same height lower than the upper surface of the craft door. The upper distance measuring sensor in this embodiment is a photoelectric sensor. When the process door rises to the...

Embodiment 2

[0048] Generally speaking, the process door has two typical working positions during use: the closed position of the process door and the in-situ position of the process door (that is, the position used to pick and place the film). This embodiment will detect the position accuracy and levelness state of the process door at the original position.

[0049] Figure 4 It is a top view of the lower ranging sensor of the process door and the detection device of the second embodiment of the present invention. In the present invention, the lower end surface of the process door is connected with the support plate through the supporting structure, so that when the lifting device drives the support plate to lift, the process door also lifts and lowers with the support plate. The detection device of this embodiment includes at least three lower ranging sensors and a detection unit. See Figure 4 The lower distance measuring sensor is arranged on the craft door. Specifically, the three lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com