Method for rapidly leveling surface

A fast and leveling technology, applied in the field of mechanical processing, can solve the problems of heavy leveling equipment and difficult handling, and achieve the effects of reducing labor intensity, avoiding movement, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

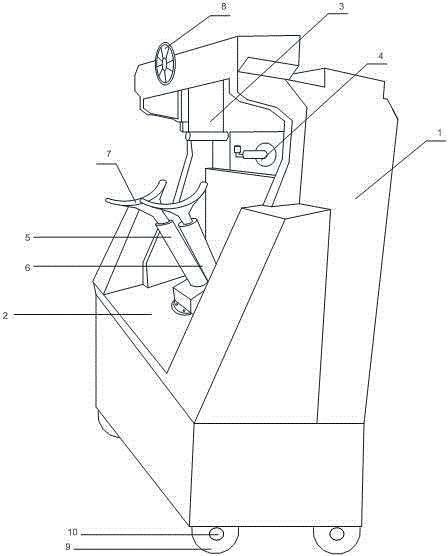

[0019] Such as figure 1 As shown, the present embodiment includes a frame 1, a support mechanism and a leveling structure. The frame is provided with an operation platform 2, the support mechanism is arranged on the operation platform 2, and the leveling mechanism is arranged on the frame 1. The leveling mechanism includes a lower Indenter 3 and leveling roller 4, the lower indenter 3 is slidably arranged on the top of frame 1, and said leveling roller 4 is arranged on the top of the support mechanism and is connected with frame 1; it also includes a motor arranged in frame 1, said The output end of motor links to each other with the rotating shaft of leveling roller 4, and frame 1 is also provided with a plurality of universal wheels 9, and universal wheel 9 is also provided with brake 10. The console 2 set on the frame 1 is convenient for taking and placing the shoes to be processed. The support mechanism can move on the console 2 through gear engagement. After the shoes are...

Embodiment 2

[0022] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the support mechanism includes a support column A5 and a support column B6, and the support column A5 and the support column B6 are movably arranged on the frame 1. According to the difference in size and type of shoes, The support mechanism is divided into two parts, which can be used to place a variety of shoes, which is convenient for adjusting the position of the shoes during processing; the support column A5 and the support column B6 are equipped with U-shaped joints 7, and the U-shaped storage platform is conducive to the smoothness of the shoes, avoiding When the shoes are in contact with the leveling roller 4, they are displaced or fall out of the support mechanism, which affects the leveling efficiency; the distance between the support column A5 and the support column B6 is 22-28cm, and the size of the shoes is roughly 35-45 yards Inside, the conversion into length measurement unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com