Self-sweeping blending machine

A mixer and self-cleaning technology, applied in mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve problems such as cross-contamination, and achieve the effect of solving cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

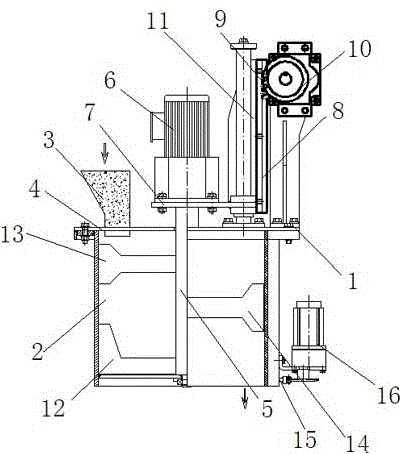

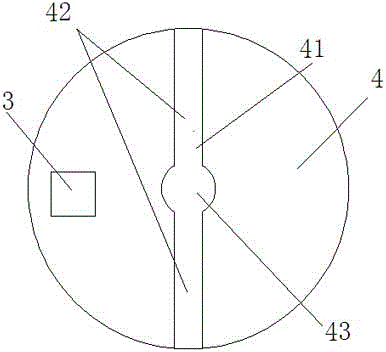

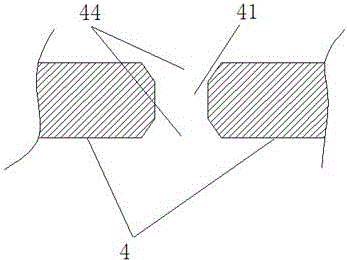

[0012] The present invention is further explained in detail in conjunction with the accompanying drawings, each of which is marked as: 1; rack; 2: mixing chamber; 3: feed inlet; 4: upper cover; 41: gap; Circular seam; 44: horn-shaped mouth; 5: rotating shaft; 6: rotating shaft driving device; 7: connecting plate; 8: rack; 9: gear; 10: lifting driving device; 11: guide column; 12: Lower blade; 13: Upper blade; 14: Middle blade; 15: Fan-shaped door; 16: Door opening and closing motor; 17: Right scraper; 18: Left scraper; 171: Limit rod, 172: Limit part ; 173: shaft hole seat; 174: spring; 175: upper slope; 176: lower slope; 177: rubber layer. As shown in the accompanying drawings, a self-cleaning mixer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com