Hydraulic control three-jaw chuck device with function of preventing blockage of iron chips

A three-jaw chuck and functional technology, which is applied in the field of mechanical parts processing tools, can solve the problems of iron filings stuck, time-consuming, jaws stuck, etc., and achieve the effect of fast operation process, improved processing accuracy, and small labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

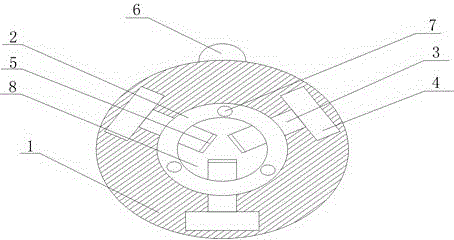

[0019] Such as figure 1 As shown, the present invention has a hydraulically controlled three-jaw chuck device with the function of preventing iron filings from clogging, comprising a disc body 1 and jaws 3, the disc body 1 is cylindrical, and a fan 6 is arranged on the outer wall of the disc body 1. The fan 6 is a miniature fan to ensure that the disk body 1 will not fall off during the rotation process. The disk body 1 is provided with a ring shaft 2, which is located at the axis of the disk body 1 and at the center of the ring shaft 2. There are through holes 8, and there are still some air outlet holes 7 on the ring shaft 2. The aperture size of the air outlet holes 7 is 0.5-0.8cm, and the air outlet holes 7 are evenly located on the surface of the ring shaft 2. The air outlet hole 7 is connected, and the duct sends the wind generated by the fan 6 to the air outlet hole 7 through the duct, and the air outlet 7 blows the wind generated by the fan 6 evenly on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com