Guide post for EPS (Expandable Polystyrene) plastic foam mold

A plastic foam and mold guide post technology, applied in the field of molds, can solve the problems of guide post deformation, component position deviation, and fast descending speed of the guide post, and achieve the effects of reducing deformation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

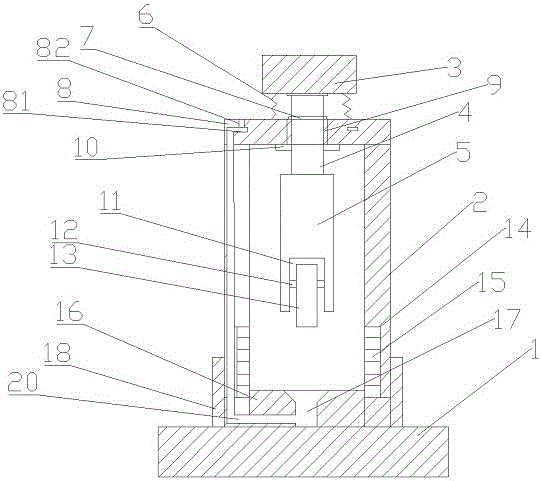

[0021] Such as figure 1 As shown, an EPS plastic foam mold guide column includes a base 1, a guide sleeve 2 threadedly connected with the base 1, an end cover 8 is arranged on the top of the guide sleeve 2, and a guide hole 7 is provided on the end cover 8, and the guide hole 7 A guide post A4 is arranged inside, a sliding sealing gasket is installed between the guide hole 7 and the guide post A4, a rubber pad 10 is provided on the lower surface of the end cover 8, and an annular channel 81 is provided on the end cover 8, and the annular channel The top of 81 is provided with the ventilation hole 82 that communicates with it, the rubber pad 10 is fixed on the periphery of guide post A4, the baffle plate 3 is installed on the top of guide post A4, the bottom of guide post A4 is detachably connected with guide post B5, the guide post B5 The bottom is provided with a mounting groove 11, the two sides of the mounting groove 11 are equipped with stoppers 12, iron posts 13 are fixed...

Embodiment 2

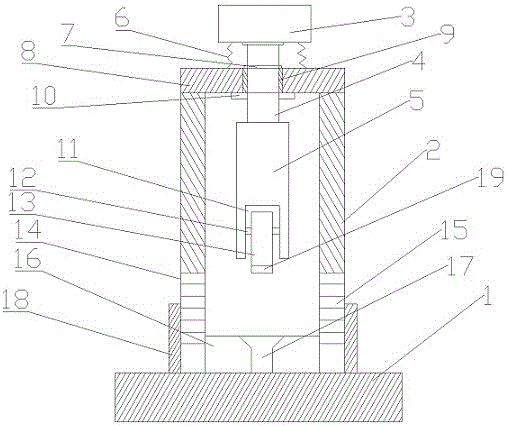

[0024] Such as figure 2 As shown, the bottom of the iron column 12 is provided with a second magnet block 19 , and the second magnet block 19 repels the first magnet block 15 .

[0025] When this embodiment is used, since the second magnet block 19 and the first magnet block 15 repel each other, a buffering effect is given to the guide post during the descent of the guide post, and the guide post is limited so that the bottom of the guide post B5 Installed iron columns will not shift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com