Large aircraft fuel system test device

A fuel system and test device technology, which is applied in the aviation industry, can solve problems such as waste of use costs, damage to oil filter elements, and large measurement errors, and achieve the effects of reducing costs, improving efficiency, and improving equipment durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

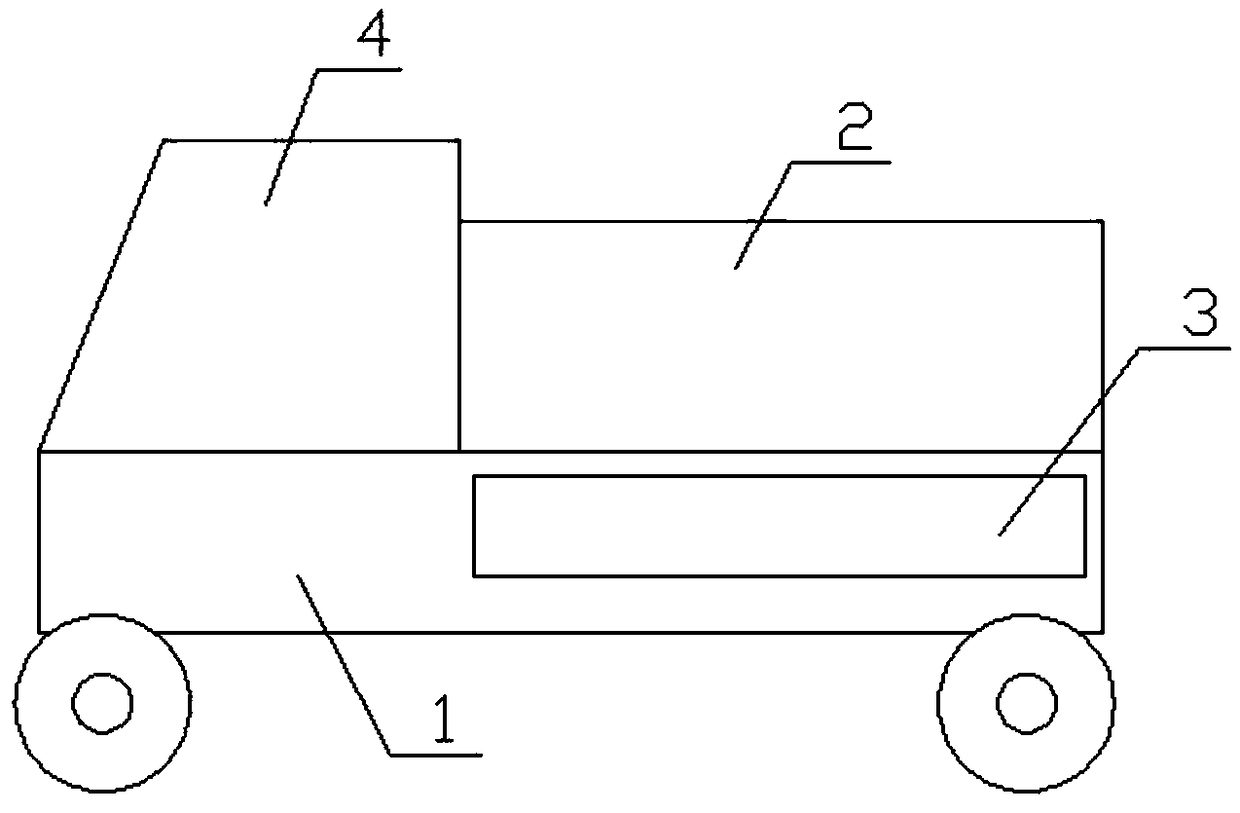

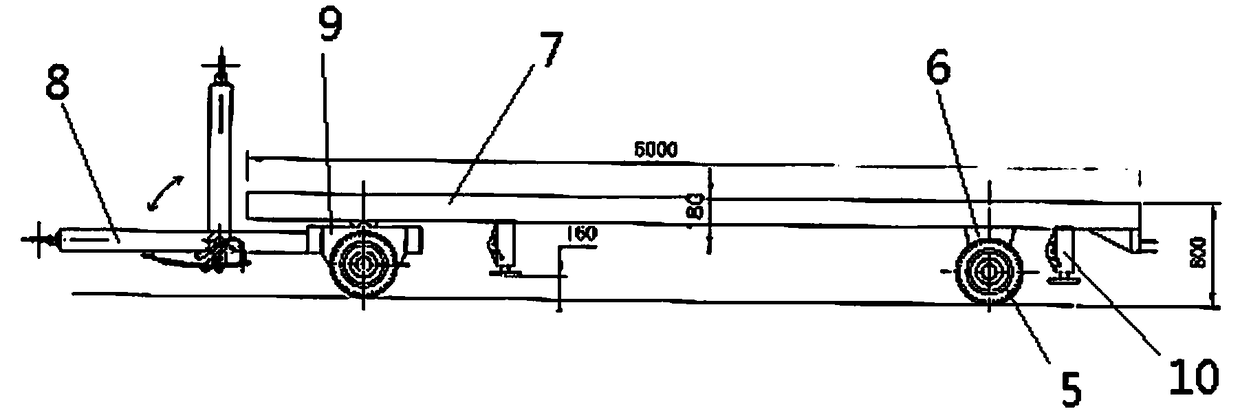

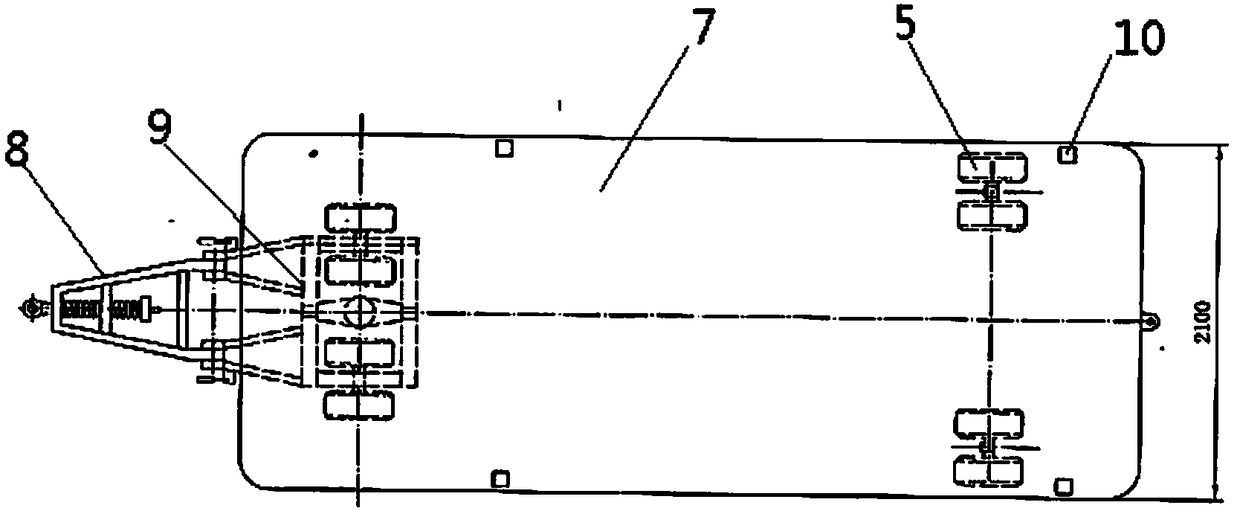

[0028] figure 1 The specific embodiment of the present invention is shown: a large aircraft fuel system test device, including a trailer 1, a tank-like fuel tank 2, a purification refueling module 3 and an electronic control module 4, and the tank-like fuel tank 2 is fixedly connected to the side of the trailer 1 At the top, the purification and refueling module 3 is arranged on the trailer 1 and connected to the tank-shaped fuel tank 2, and the electronic control module 4 is arranged on the trailer 1 and connected to the purification and refueling module 3 through wires , the device transports the tank-shaped fuel tank 2 to a designated position through the trailer 1, and then the electronic control module 4 controls the purification and refueling module 3 to realize multiple functions. The device has four functions: aircraft gravity refueling, transfer fuel tank Aircraft refueling, transfer fuel tank purification, and self-circulation purification functions can independently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com