Anti-material leakage device for high mobility, powder material packaging machine

A high fluidity, packaging machine technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve problems such as waste, leakage of high fluidity powder, and impact on packaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

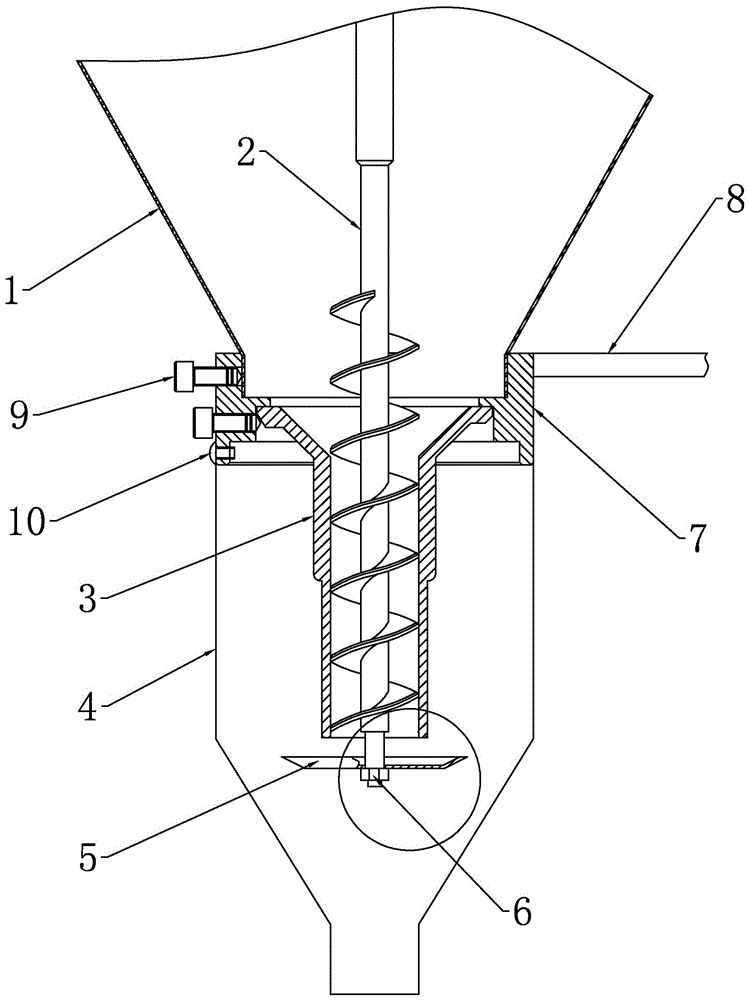

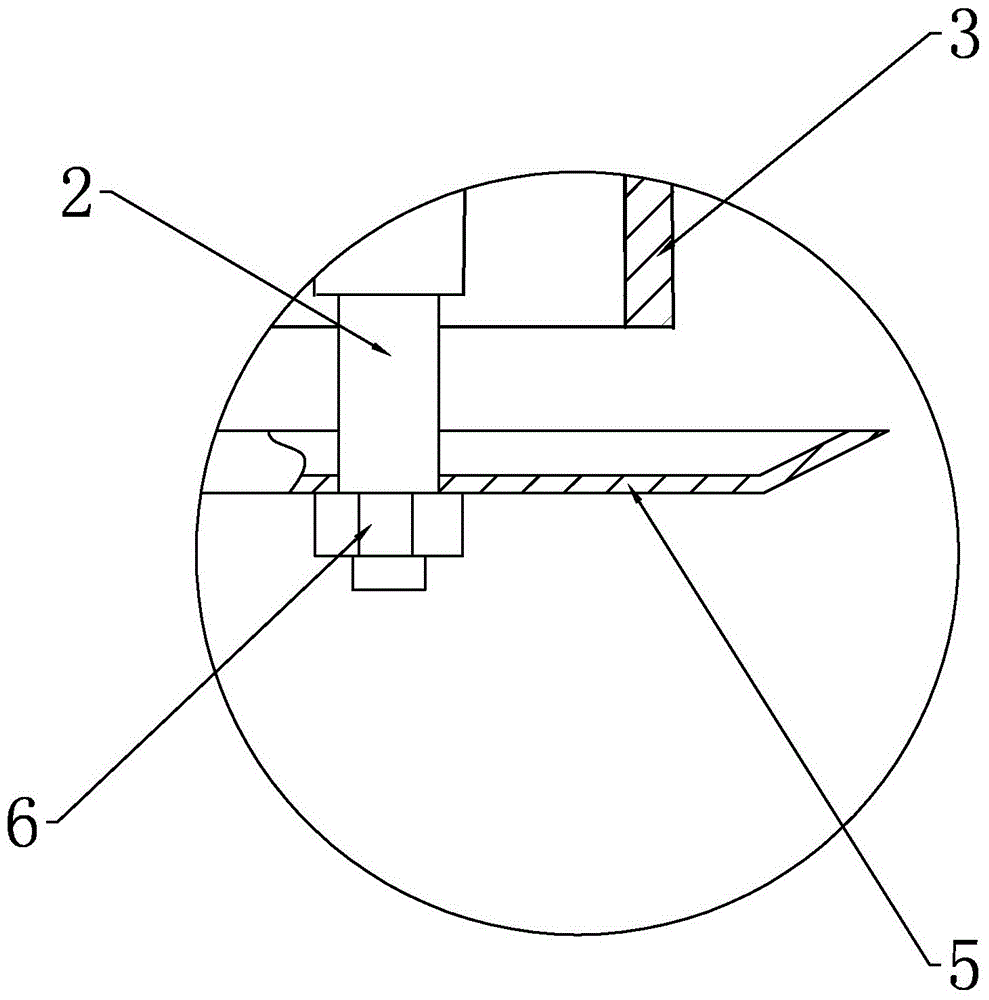

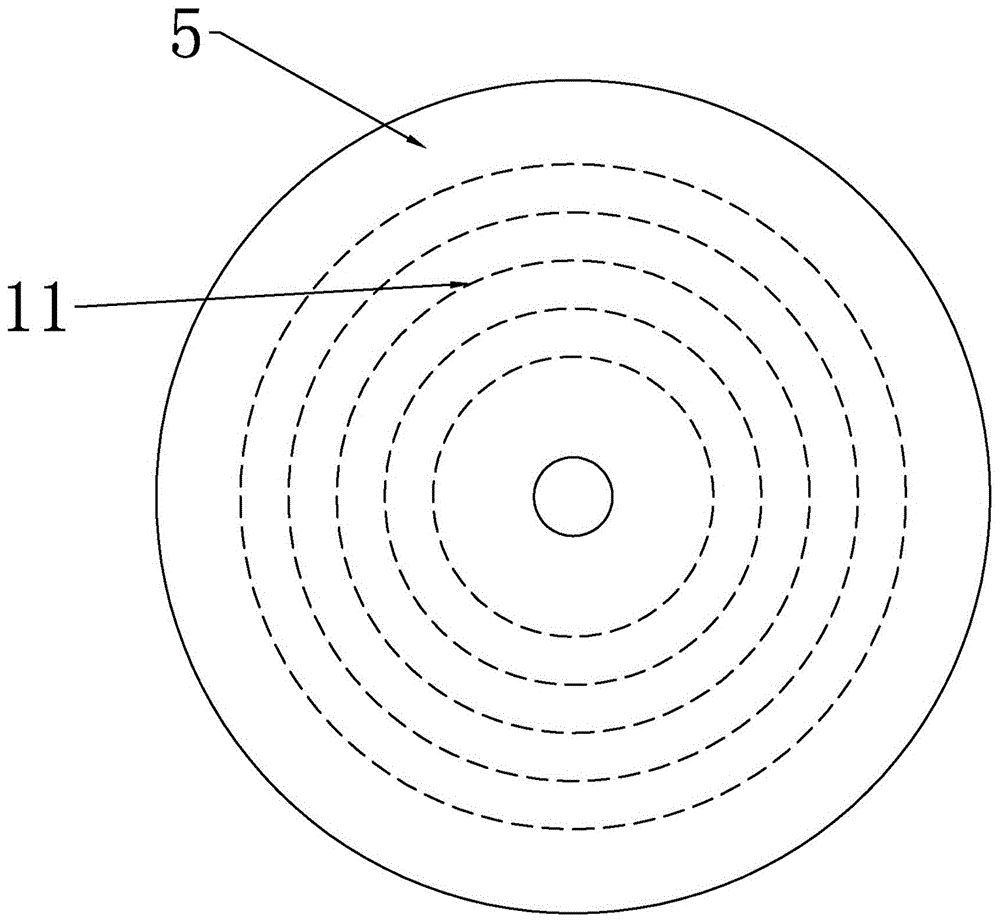

[0012] A kind of anti-leakage device of high fluidity powder packaging machine, see Figure 1-3 : Including a silo, a material guide screw and a throwing plate, the material guide screw includes a material guide tube and a screw that match each other, the upper end of the vertically arranged material guide tube is connected to the discharge port of the hopper, and the upper end of the screw extends upwards after the hopper Correspondingly connected to the drive motor, the upper end protrudes downwards from the material guide tube and is equipped with a spinner, and the outer edge of the spinner rises to form warped edges.

[0013] The material guide pipe and the feed bin are transferred through an adapter, and the upper or lower edge of the transfer interface is provided with a step platform corresponding to the discharge port of the feed bin or the upper edge of the feed pipe; the side wall of the transfer interface is provided with a corresponding material guide The screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com