Centrifugal pump accelerating device and system

A technology of speed increasing device and centrifugal pump, applied in pump device, transmission device, pump and other directions, can solve the problems of high cost, large bearing box, high cost, etc., and achieve the effect of low cost and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 provides a speed increasing device for a centrifugal pump, which can realize a wide range of adjustment of the rotational speed of the centrifugal pump 3 under the joint action of the pulley transmission mechanism 2 and the driving mechanism 1 . Moreover, the installation of the centrifugal pump 3 and the drive mechanism 1 on different axes is realized, the installation is more flexible and convenient, and it can adapt to various working conditions.

Embodiment 2

[0047] Embodiment 2 provides a centrifugal pump speed-up system, including the centrifugal pump speed-up device and the centrifugal pump 3 provided in Embodiment 1. The centrifugal pump speed-up system can realize the centrifugal pump 3 under the action of the centrifugal pump speed-up device. Wide range of speed adjustment.

[0048]Embodiment 1 and embodiment 2 are described in detail below in conjunction with accompanying drawing:

[0049] Example 1

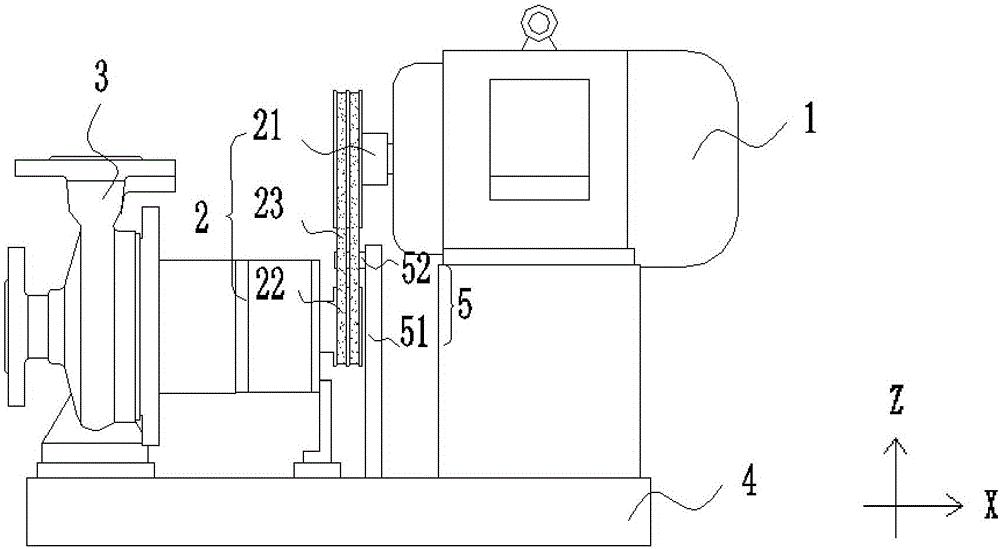

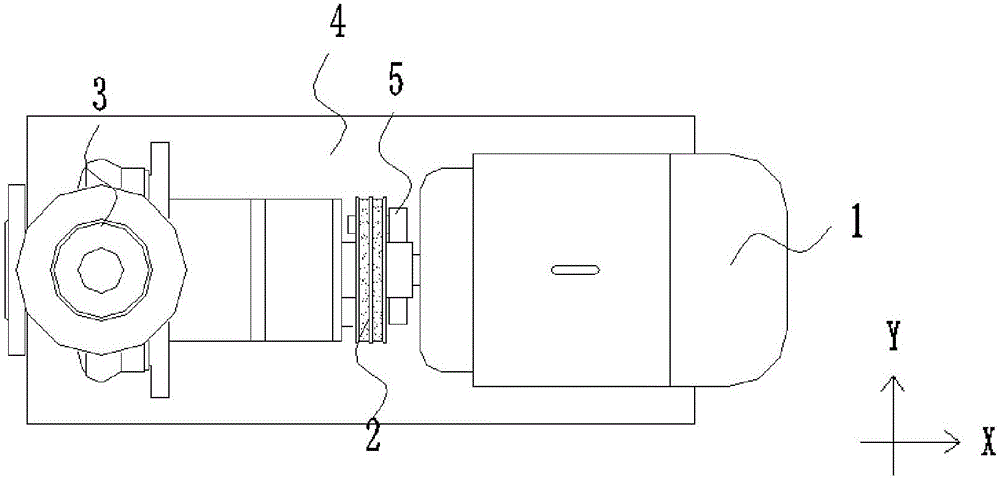

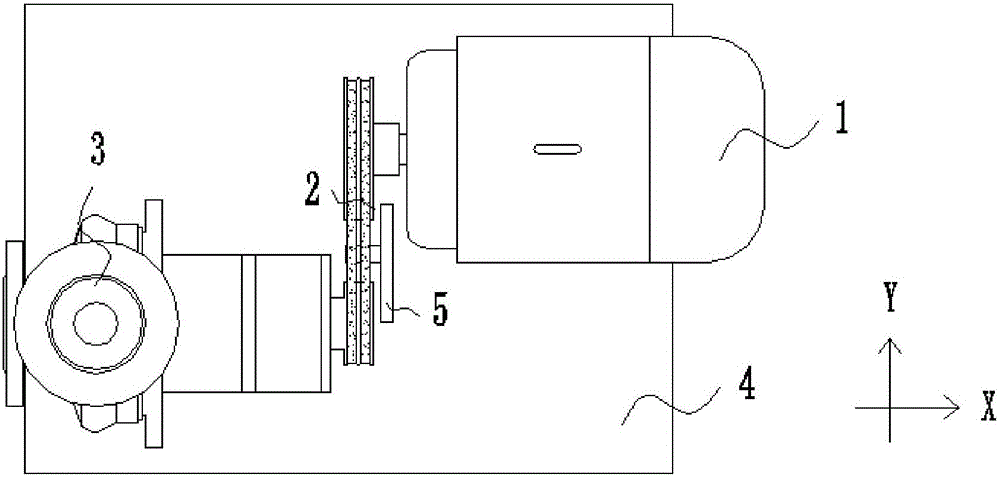

[0050] This embodiment provides a speed increasing device for a centrifugal pump, including a drive mechanism 1 and a pulley transmission mechanism 2, the centrifugal pump 3 and the drive mechanism 1 are fixed on the bottom plate 4, and the pulley transmission mechanism 2 is located between the drive mechanism 1 and the centrifugal pump 3 For connecting drive mechanism 1 and centrifugal pump 3.

[0051] The pulley transmission mechanism 2 includes a driving pulley 21 located at the end of the drive mechanism 1 and rotatably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com