Probe ageing test device and method for three-electrode conductivity sensors

A conductivity sensor and aging experiment technology, applied in measuring devices, instruments, measuring electrical variables, etc., can solve the problems of high labor cost, complex aging experiment process, inability to guarantee the consistency of aging experiments, etc., to reduce labor costs, improve The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples.

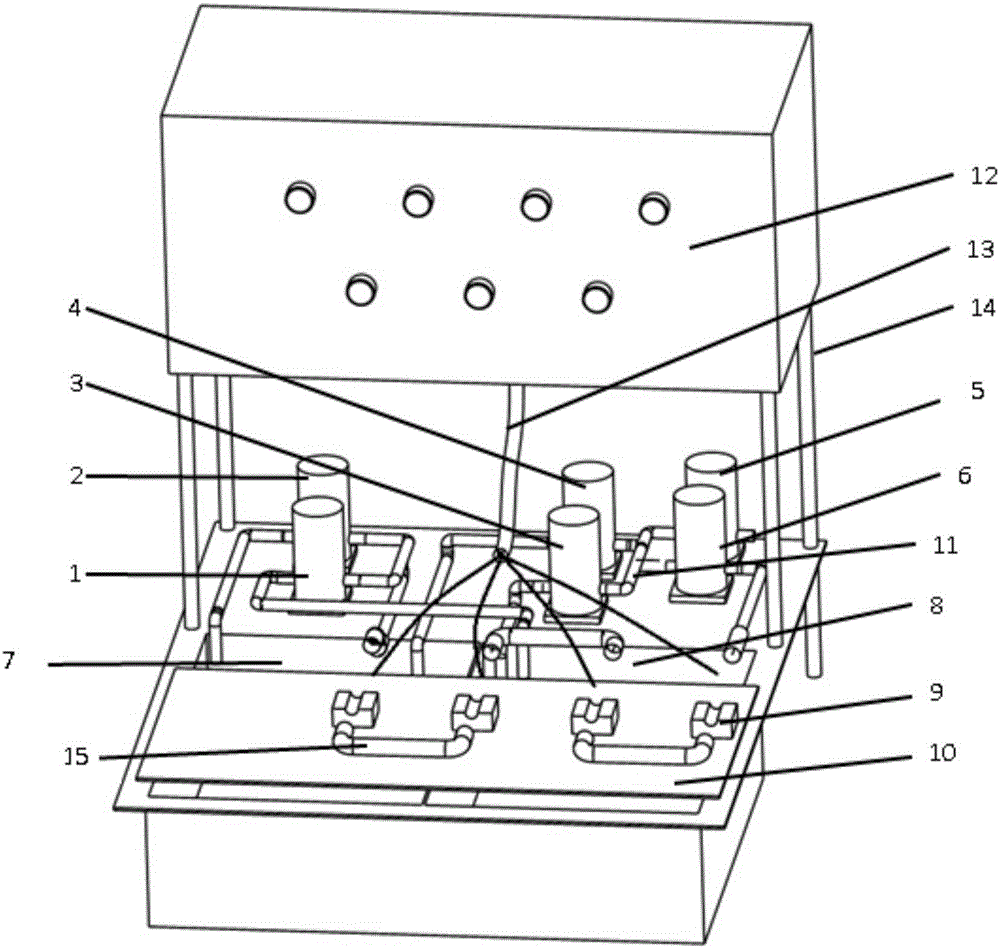

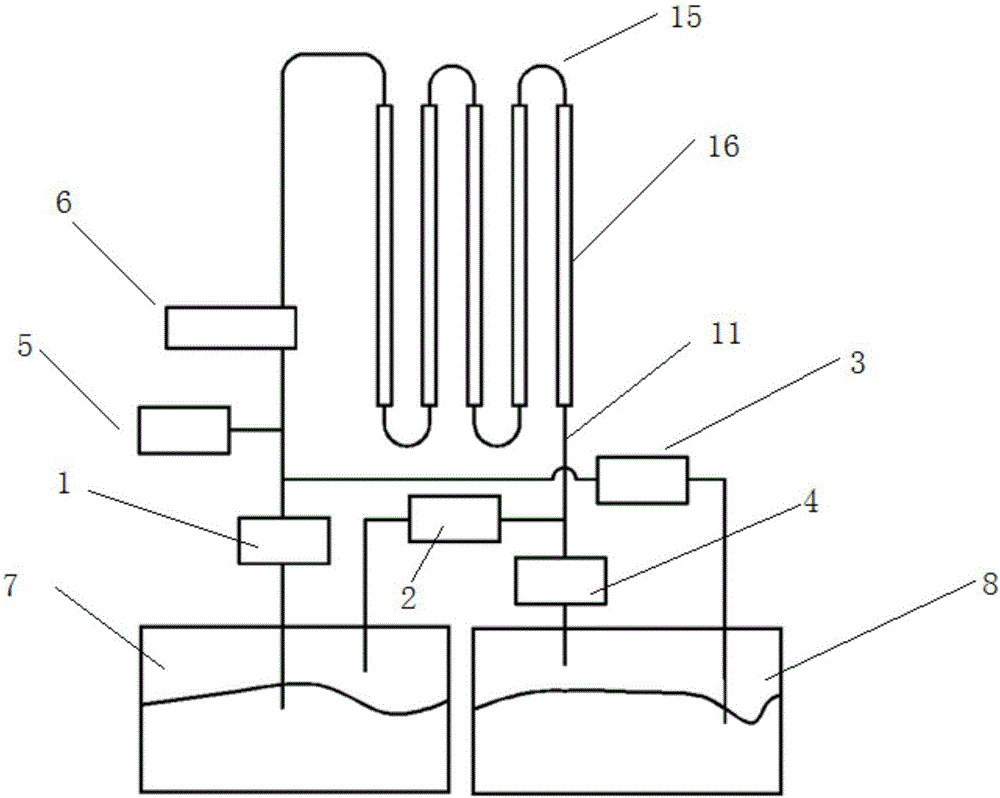

[0045] The present invention relates to a three-electrode conductivity sensor probe aging test device such as figure 2 As shown, it includes control box 12, probe connection line 13, support column 14, suction pump 6, first normally closed electric valve 1, second normally closed electric valve 2, third normally closed electric valve 3, fourth normally closed electric valve Valve 4, fifth normally closed electric valve 5, pipeline connecting pipe 11, fresh water tank 8, sea water tank 7, probe fixing block 9, fixing block supporting plate 10, and probe connecting hose 15 are composed.

[0046] The rectangular seawater tank 7 and the rectangular freshwater tank 8 are installed side by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com