Novel wafer compressing mechanism

A compression mechanism and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of no compression mechanism, high defect rate of wafer warping products, etc., to achieve product yield improvement, structure compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

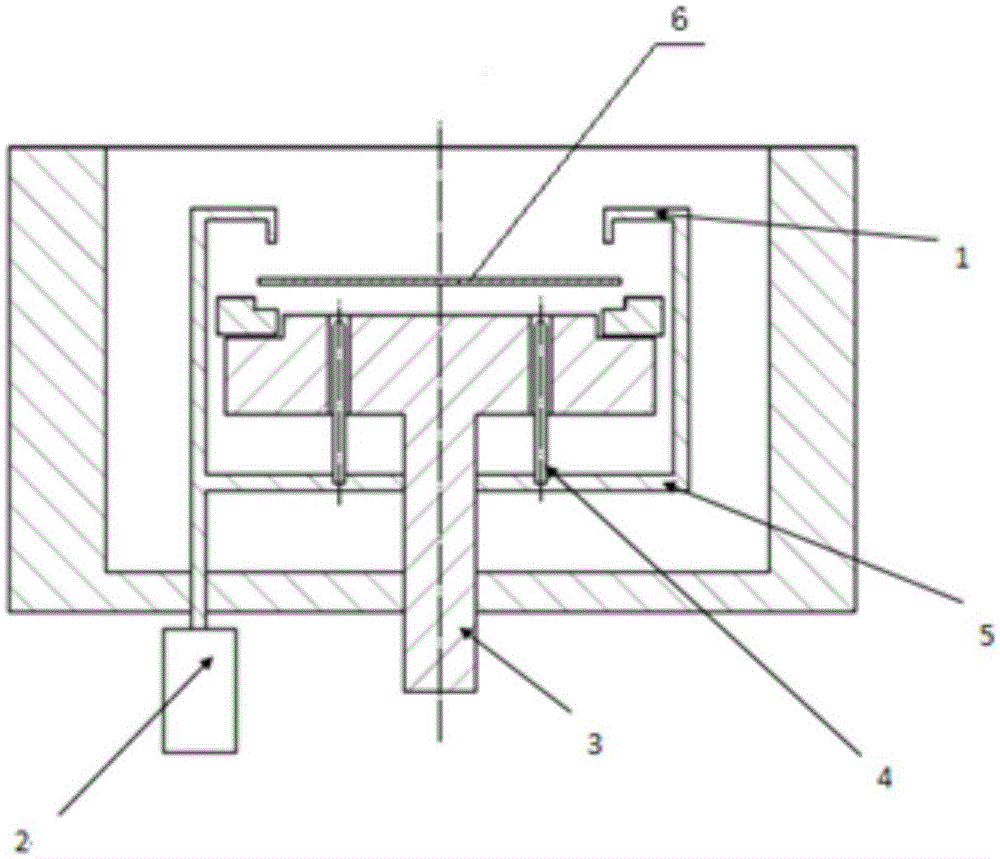

[0012] refer to figure 1 , a novel wafer pressing mechanism, the mechanism includes a main body, the main body is connected with a motor 2 . The main body includes a pressing plate 1 , a heating plate 3 , a thimble 4 and a tray 5 . The upper and lower ends of the thimble 4 are respectively arranged in the inner holes of the heating plate 3 and the tray 5, and slide up and down in the inner holes. The upper end of the above-mentioned pressing plate 1 is in an inverted "L" shape.

[0013] When in use, the pressing plate 1 is driven by the linear motion of the motor, so that the pressing plate 1 tightly presses the wafer 6 to ensure the flatness of the wafer 6 . When the tray 5 lifts the ejector pin 4 to raise the wafer 6, the platen 1 will also rise simultaneously. The stroke of the pressing plate 1 is 5mm larger than that of the thimble to meet the requirements of use and ensure the stability of the cavity during the operation of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com