Cover body opening closing device and equipment provided with the same

A technology for opening and closing devices and covers, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc. The problem of body opening and other problems is solved, and the effect of smooth operation and improved operability is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

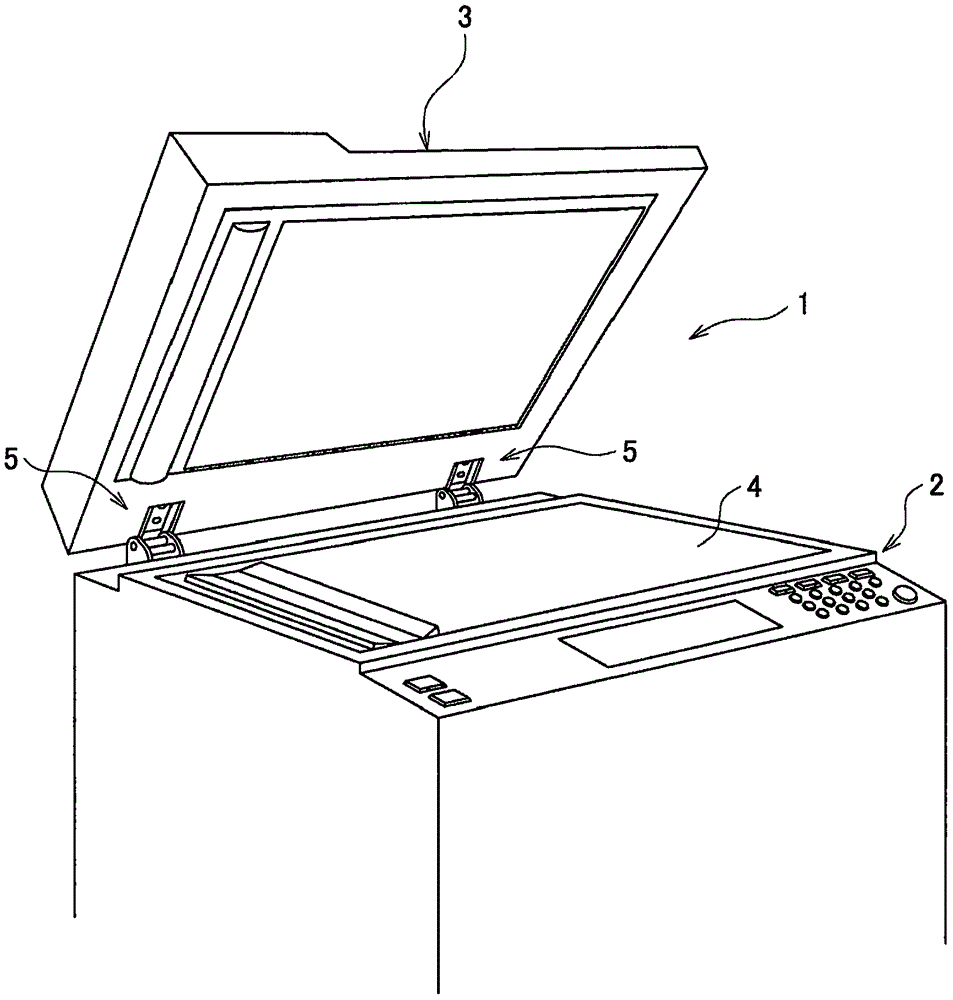

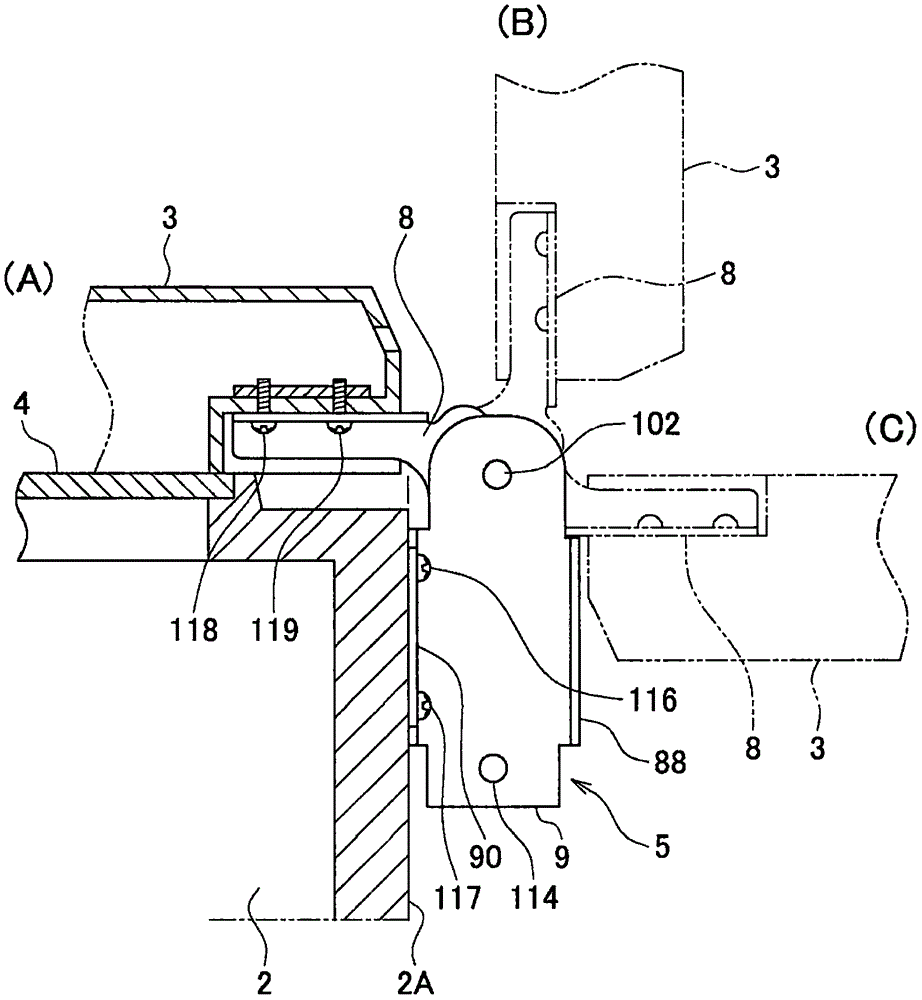

[0032] Figure 1 to Figure 7 It is a schematic diagram of the cover opening and closing device 5 and the office machine 1 equipped with the cover opening and closing device 5 according to the first embodiment of the present invention, wherein the office machine 1 is an example of equipment. as the picture shows, figure 1 It is a schematic view of the appearance of a compound machine as an example of an office machine, in which the cover body 3 is assembled to the device body 2 in an openable and closable manner. The upper surface of the device body 2 is provided with a contact glass 4 on which the original is placed, and the cover 3 presses the original to one side of the contact glass 4 for copying or printing. In addition, the equipment of the present application is not limited to a multifunction machine or a copier, but may be other office equipment such as a printing machine or equipment for other production equipment.

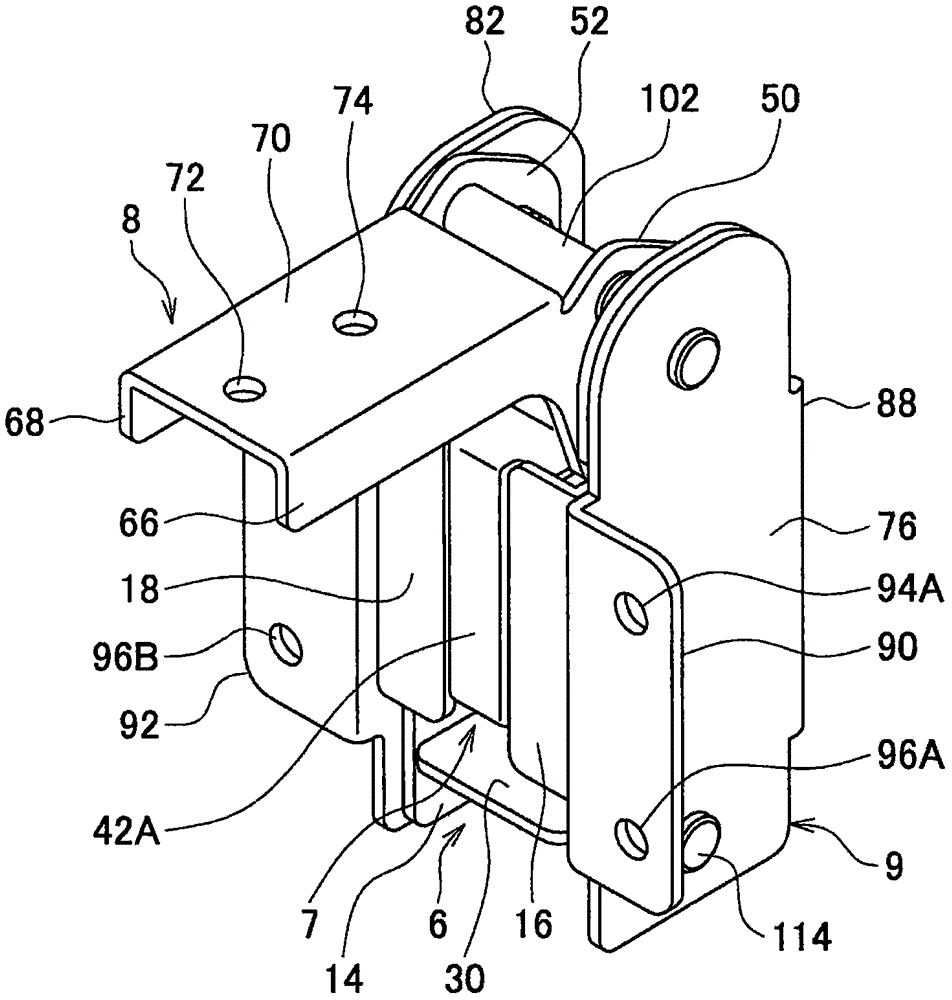

[0033] figure 2 The support element 8 of the cov...

Embodiment 2

[0078] Figure 8 and Figure 9 is a schematic diagram of another embodiment of the present invention. In the lid opening and closing device 120 of the second embodiment, the assembly components are made of synthetic resin. Compared with this embodiment, the lid opening and closing device 5 of Embodiment 1 includes a slider case 6, a slider 7, a support element 8, an assembly element 9 and an elastic element 91, but the lid opening and closing device 120 of Embodiment 2 does not There is a slider case 6, so its structure is simpler than that of the lid opening and closing device 5 of the first embodiment.

[0079] The assembly element 121 made of synthetic resin includes a polygonal cylindrical shell portion 121d and assembly plate portions 121e, 121e, wherein the shell portion 121d is composed of a front plate portion 121a, a rear plate portion 121b, and two side plate portions 121c, 121c. The front plate portion 121a and the rear plate portion 121b are integrally formed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com