Converter device and converter device manufacturing method

A manufacturing method and converter technology, applied to electrical components, sealed enclosures, electrical equipment enclosures/cabinets/drawers, etc., can solve problems such as difficulties in miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of an inverter device and a method of manufacturing the inverter device (hereinafter also simply referred to as "manufacturing method") will be described with reference to the drawings.

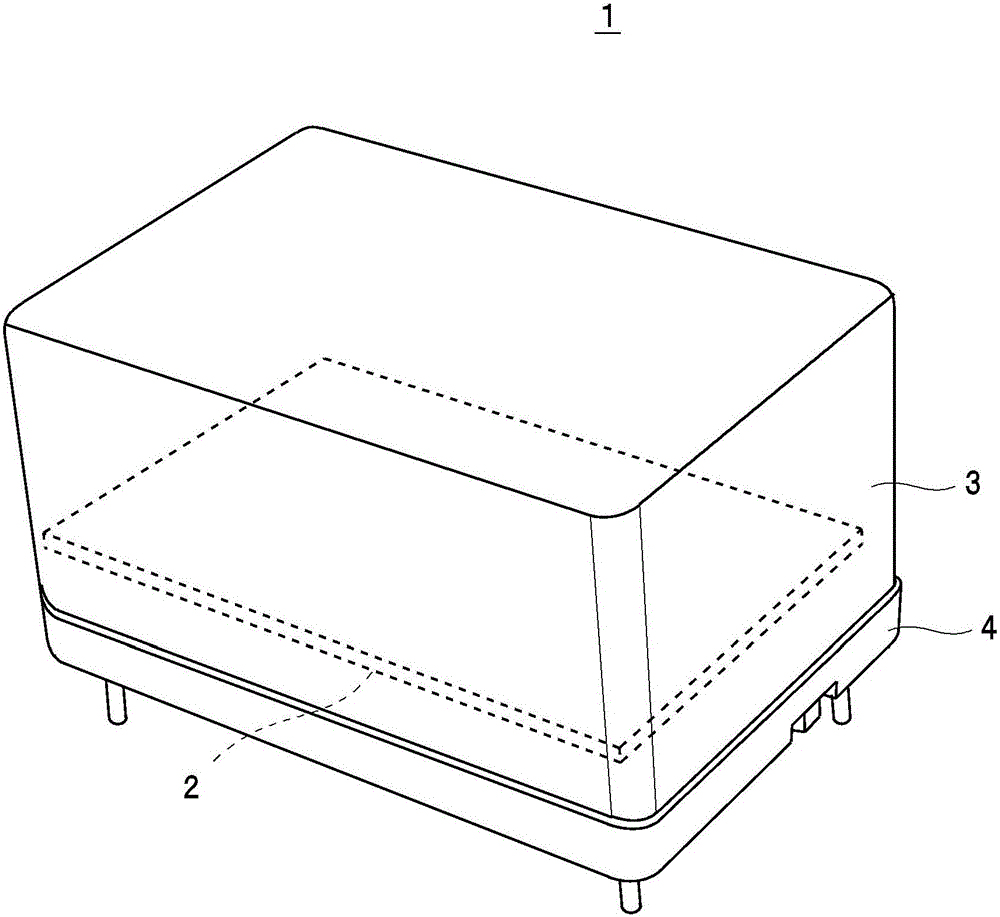

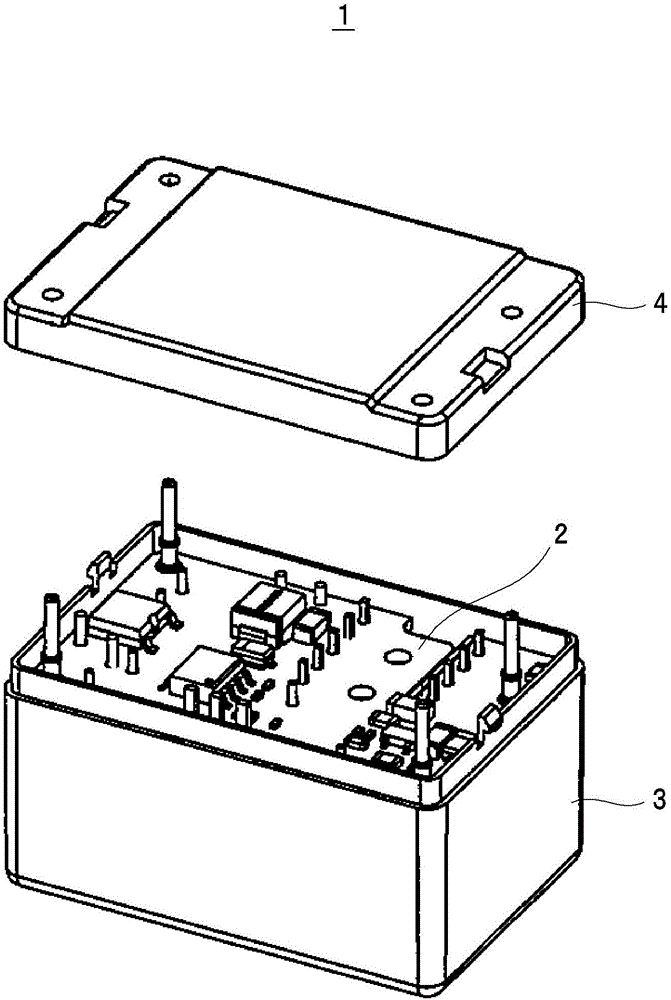

[0034] First, as an example of a converter device figure 1The structure of the shown converter device 1 is explained as follows. The converter device 1 is, for example, an AC-DC converter that inputs an alternating current and outputs a direct current, such as figure 1 as well as figure 2 As shown, it is constituted by including a mounting substrate 2 , a frame body 3 , and a cover portion 4 . In addition, in this converter device 1, as Figure 10 As shown, the filler 5 is filled in the frame body 3 .

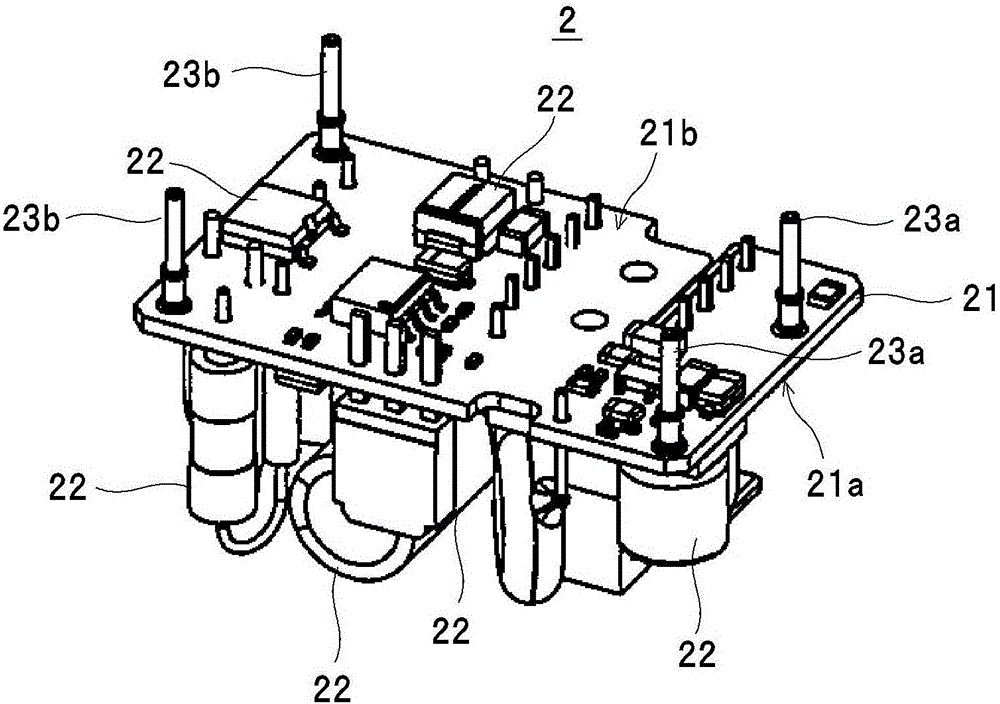

[0035] Mount substrate 2 as image 3 As shown, it is constituted by including a substrate 21 and various electrical components 22 mounted on the substrate 21 . The substrate 21 is formed in a substantially rectangular shape (for example, a substantially r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com