Underground ventilated premixing chicken house

An underground ventilation and pre-mixing technology, which is applied in the field of chicken houses, can solve the problems of inability to mix hot air evenly, difficulty in raising the temperature of chicken houses, and large air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

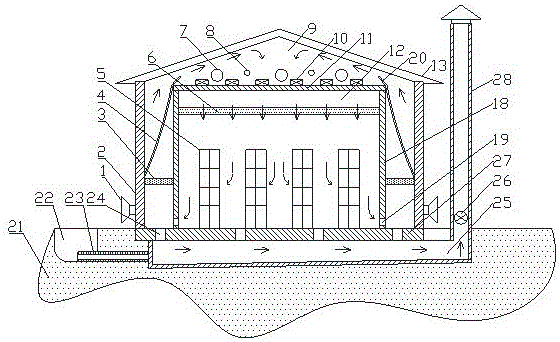

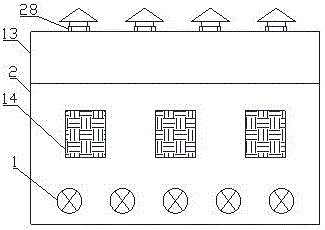

[0037] see figure 1 and figure 2 , the present invention is a kind of pre-mixed underground ventilated chicken house, comprising gable, side wall 2, roof 13 and floor 27, wherein, the inner chamber parallel to side wall 2 is arranged in the middle of the chicken house, and the breeding cage 5 of the chicken house is located Inner room; the inner room includes an inner wall 18 parallel to the side wall 2 and an inner roof 11;

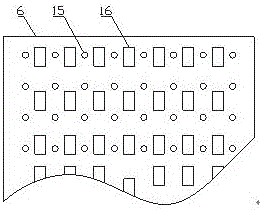

[0038] A partition 3 is sealed between the side wall 2 and the inner wall 18, and an air inlet plate 6 is arranged between the two inner walls 18 below the inner roof 11, and a pressure chamber 12 is formed between the inner roof 11 and the air inlet plate 6. A pre-mixing bin 9 is formed between the inner roof 11 and the roof 13; referring to Fig. 4, several fans 10 and several air inlet windows 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com