Picking mechanical hand

A technology of manipulator and manipulator, applied in picking machines, manipulators, program-controlled manipulators, etc., can solve the problems of reducing labor intensity of workers, complicated fruit and vegetable picking operations, and increasing the income of growers, so as to reduce manual labor, reduce picking costs, Structural mass and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

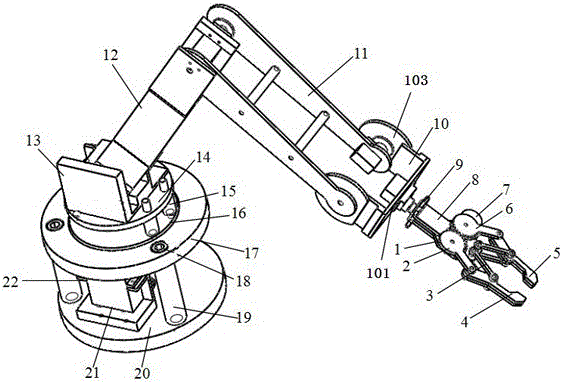

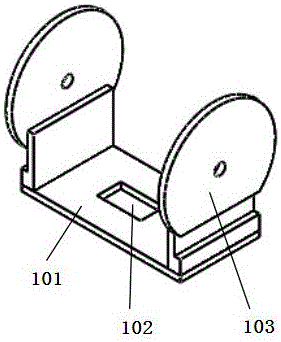

[0026] Such as Figure 1~7 As shown, a picking manipulator includes an end effector, a mechanical arm and a lifting platform, and the lifting platform is installed on a crawler vehicle that can automatically drive and navigate.

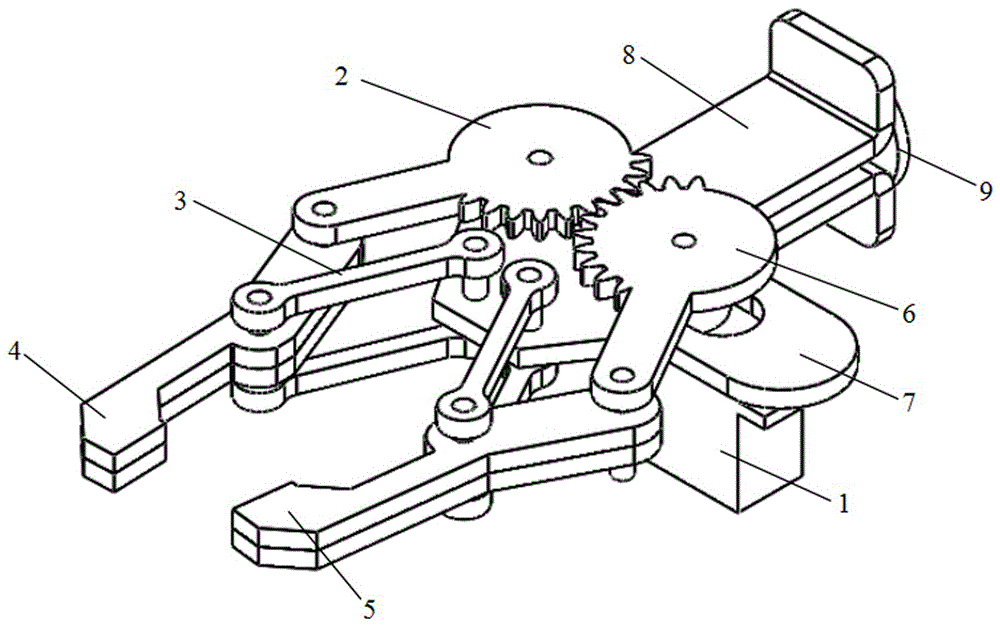

[0027] The end effector includes a clamping mechanism and a servo motor I (1). Rubber nylon material is added to the inside of the fingers of the clamping mechanism to reduce damage to the fruit surface.

[0028] DIGI-HIBW-60 video camera is set on the end effector, fsr-402 pressure sensor is set at the finger end, DIGI-HIBW-60 video camera and fsr-402 pressure sensor are connected to the controller, DIGI-HIBW-60 video camera collects the end The distance information between the actuator and the picking object and the shape and size information of the fruit, the fsr-402 pressure sensor converts the pressure at the end of the finger into an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com