A shoe making device

A clamping and shoe last technology, which is applied to household components, household appliances, and other household appliances, can solve the problem of many operating procedures, achieve the effects of reducing operating procedures, improving processing efficiency, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

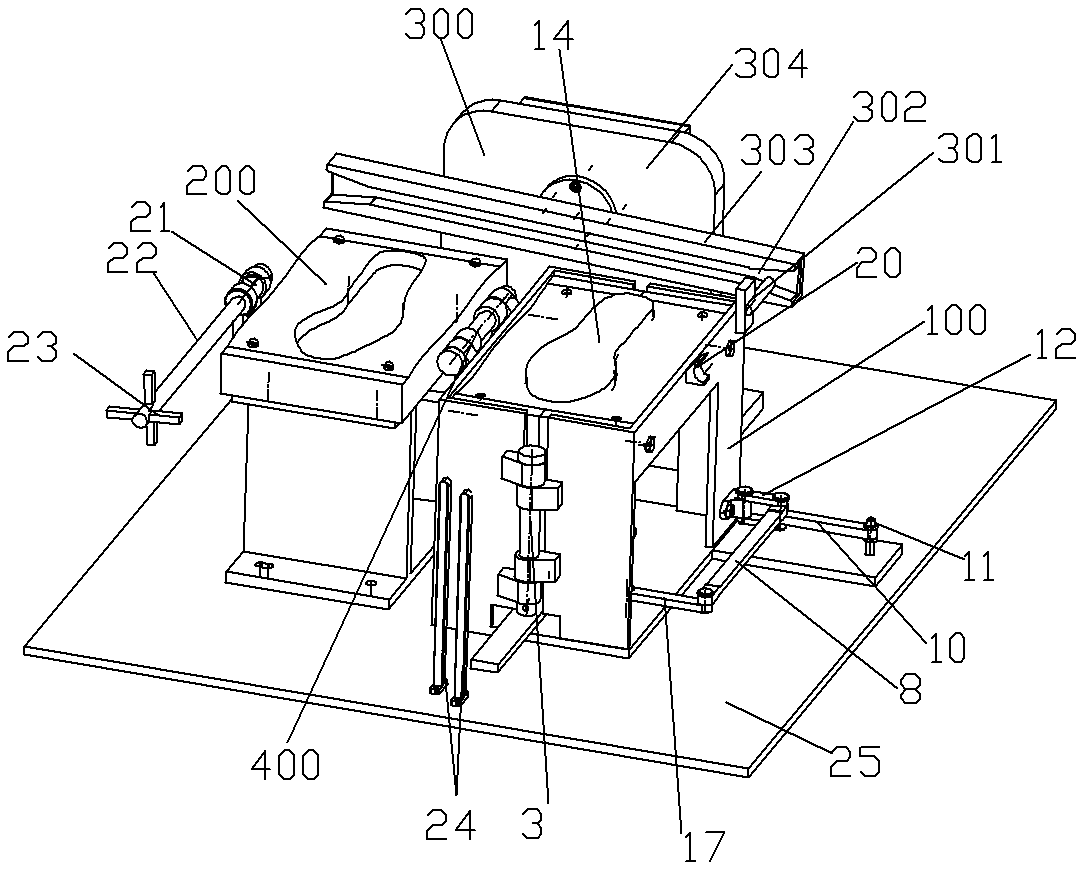

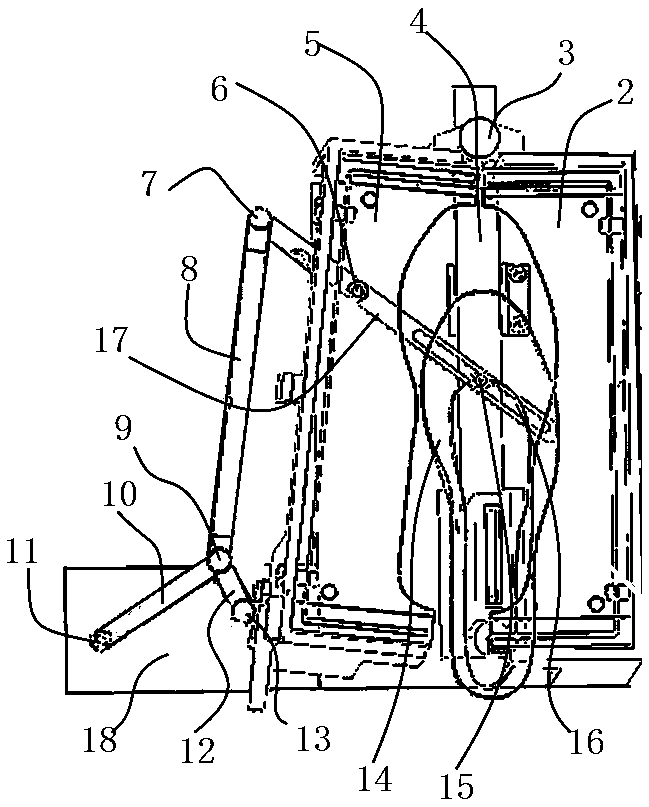

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The specific embodiment of shoe-making device provided by the present invention, as figure 1 , figure 2 As shown, the shoe-making device in this embodiment includes an installation base plate 25, on which an upper mold 100 and a lower mold 200 are assembled to move horizontally on the installation base plate 25, and the upper and lower molds are hingedly assembled together by a hinge shaft 400, and the upper mold is used for Clamp the shoe last, use the shoe last to cooperate with the groove of the lower mold to form the corresponding shoe-making cavity when the upper and lower molds are closed.

[0028] During specific use, the upper and lower molds here can be arranged on the mobile production line, that is, the installation base plate can be arranged on the mobile production line or be a part of the mobile production line, as long as the norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com