Portal crane for assembling motor with weight being above 100T

A technology for gantry cranes and motor stators, applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve problems such as quality accidents, swaying, dangerous and time-consuming, and achieve the effect of assembly quality assurance and elimination of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0021] The present invention will be further described below in conjunction with accompanying drawing.

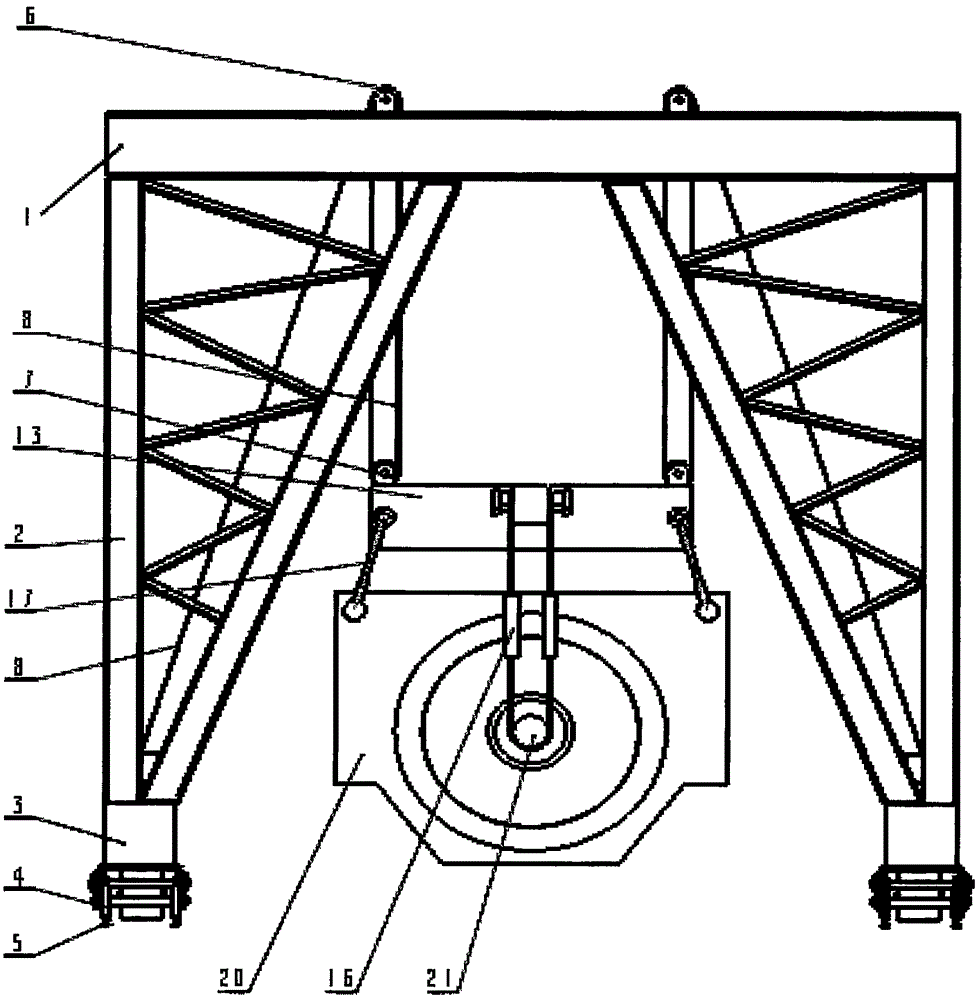

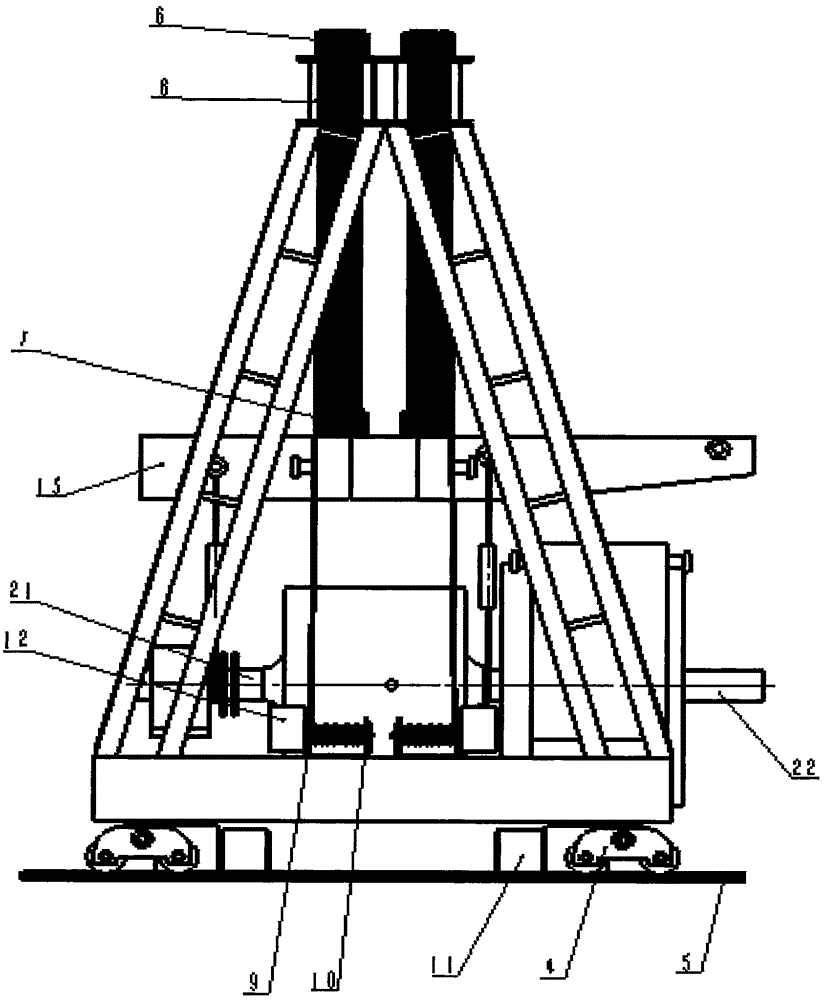

[0022] The invention provides a gantry crane, such as figure 1 As shown, it includes a load-bearing main beam 1 of a portal frame, four inverted triangular columns 2, and a bottom beam 3, wherein the upper ends of the columns are screwed or welded to the main beam, and the lower ends are screwed or welded to the upper plane of the bottom beam. Running mechanism 4 is installed at both ends of the lower plane of the bottom beam, and the speed reducer 11 on the running mechanism 4 can rise and stop on a slope. Double tracks and double tracks 5 are installed on the foundation, and the running mechanism is placed on the track 5.

Embodiment example 2

[0024] like figure 1 and figure 2 As shown, four sets of fixed pulley blocks 6 are installed on the four holes opened on the load-bearing main beam 1 of the portal frame. Fixed on the fixed pulley block 6, the other end is pulled to the reel flange 9 of the hoist 11 on the bottom beam 3 through the last pulley of the fixed pulley block 6. The hoist 11 is equipped with a reducer 12, and four sets are installed on the bottom beam 3. The winches correspond to the four groups of fixed pulley blocks 6 on the load beam 1 respectively.

Embodiment example 3

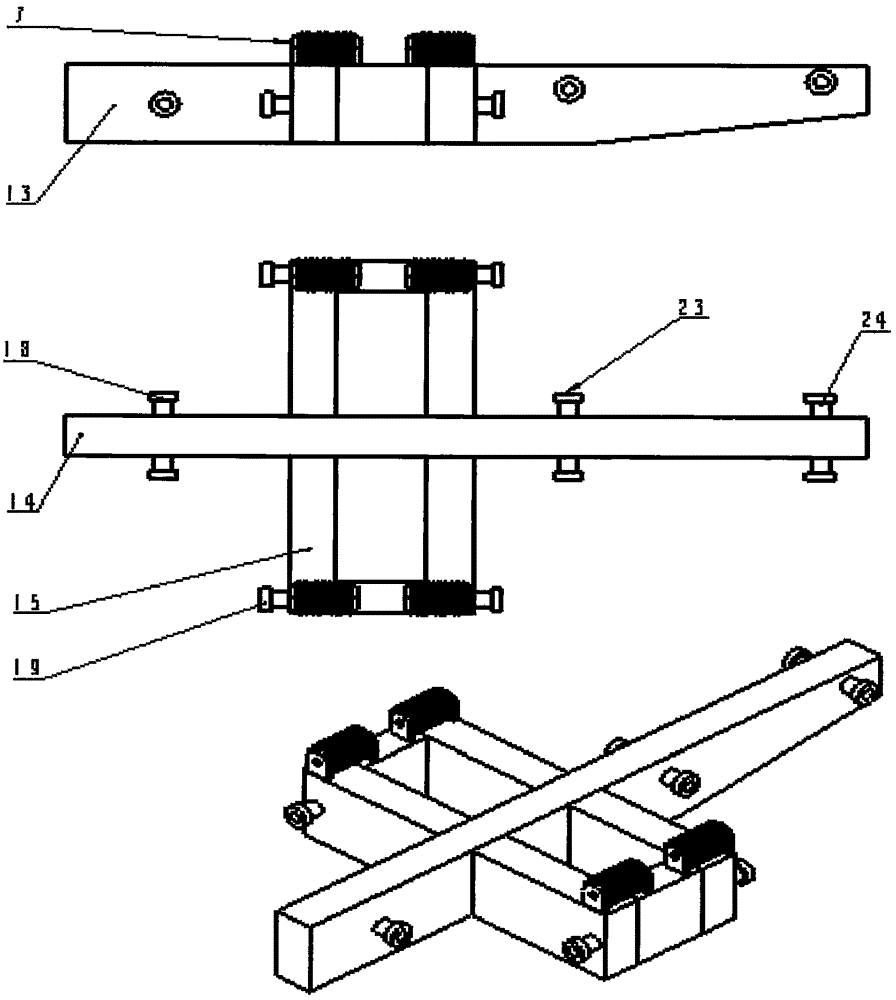

[0026] like image 3 As shown, the Chinese character load beam 13, the central longitudinal long beam 14 is the long beam for the rotor, three suspension points are respectively set according to the center of gravity on the beam, and suspension shafts are installed on each point, which are suspension shaft 18, suspension shaft 23, and suspension shaft respectively. Axis 24. At the center of gravity of the middle beam, a horizontal mouth beam 15 is designed to carry the stator 20. Four suspension shafts 19 are installed at the four corners of the wide side of the mouth beam for hoisting the stator 20. The four corners of the upper plane of the mouth beam 15 are installed Four groups of moving pulley blocks 7 have been developed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com