Process for Separation of Mild Acid Catalyzed Lignin Depolymerization Products and Its Extraction Products

A depolymerization product, lignin technology, applied in the field of natural organic polymer chemical industry, can solve the problems of separation and screening of depolymerization products, complex reaction products, etc., and achieve the effect of low cost, low process temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

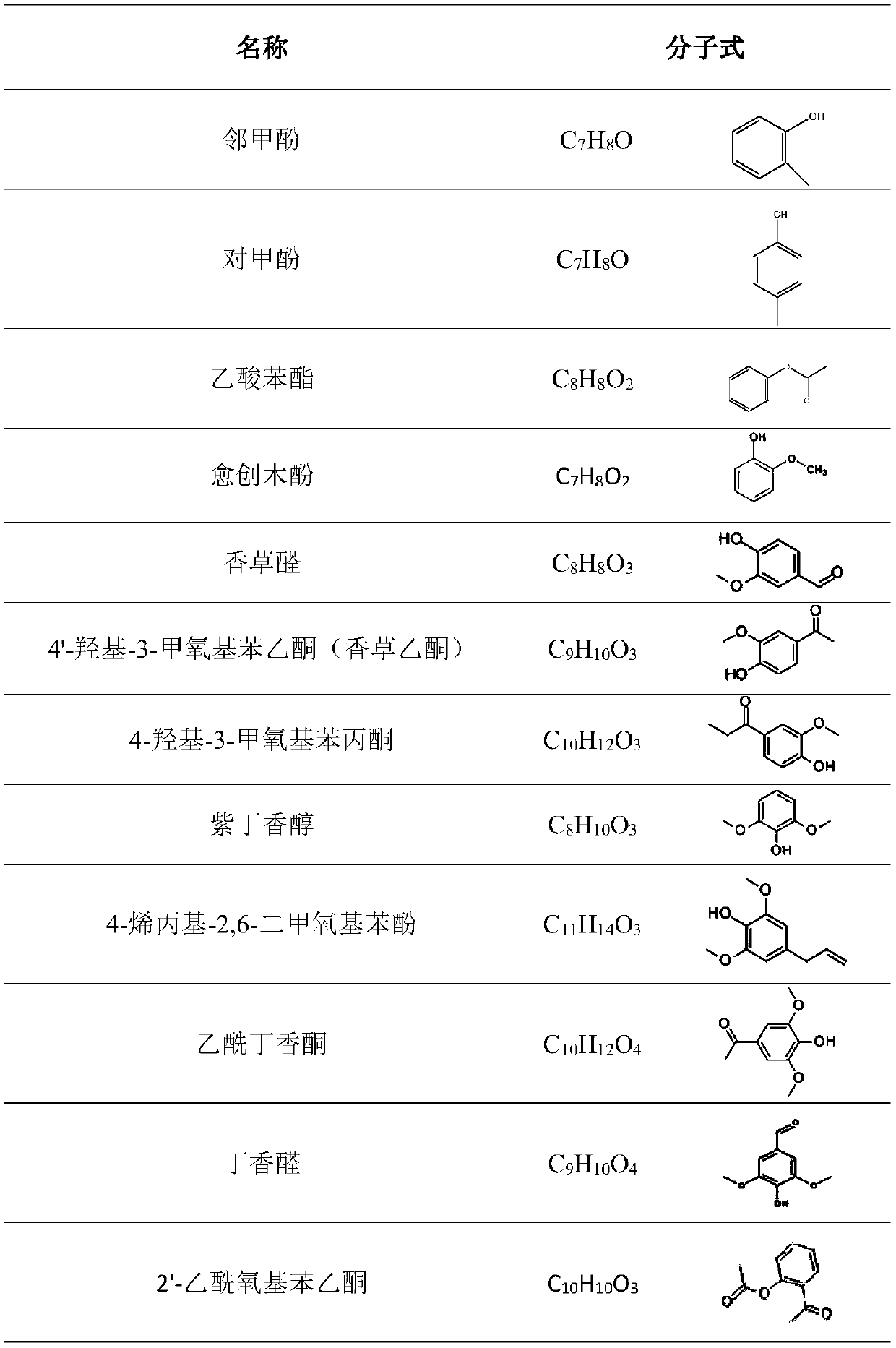

Image

Examples

Embodiment 1

[0027] (1) Using phenol as a solvent, add pre-sulfonated alkali lignin, the quality of phenol is 75g, the quality of alkali lignin is 30g, add concentrated hydrochloric acid under normal pressure conditions, heat at 94 ° C under stirring conditions, the concentration of concentrated hydrochloric acid The dosage is 4wt% of the total amount of phenol and alkali lignin. After being heated to a predetermined temperature, the heat preservation liquefaction reaction is carried out for 30 minutes to obtain the alkali lignin depolymerization product;

[0028] (2) The above-mentioned lignin depolymerization products were extracted by solvent continuous extraction, that is, the above-mentioned lignin depolymerization products were continuously extracted with diethyl ether at 50°C for 6 days, the solvent was separated, and then continuously extracted with methanol at 70°C for 1 day, Finally, the extracted product is obtained.

[0029] By adjusting the depolymerization process and separatio...

Embodiment 2

[0034] (1) Take phenol as solvent, add lignosulfonate, the quality of phenol is 5g, the quality of lignosulfonate is 20g, add concentrated phosphoric acid under normal pressure condition, heat 100 ℃ under stirring condition, the concentrated phosphoric acid The dosage is 5wt% of the total amount of phenol and lignosulfonate. After being heated to a predetermined temperature, the heat preservation liquefaction reaction is carried out for 15 minutes to obtain the depolymerization product of lignosulfonate;

[0035] (2) Use the simultaneous distillation extraction method to extract the above-mentioned lignin depolymerization products, that is, use a simultaneous distillation extraction device, one side of which is the acid-catalyzed depolymerization product, add water according to the volume ratio of 1:2, heat at 120 ° C, and the other side is acetone, Continuously extract at 70°C for 1 day, separate the solvent, continue to extract with acetic acid at 85°C for 6 days, and finally...

Embodiment 3

[0039] (1) Using phenol as a solvent, add pre-sulfonated high-boiling alcohol lignin, the mass of phenol is 50g, the quality of high-boiling alcohol lignin is 40g, add concentrated sulfuric acid under normal pressure conditions, and heat at 96°C under stirring conditions , the amount of concentrated sulfuric acid is 6wt% of the total amount of phenol and high-boiling alcohol lignin, after being heated to a predetermined temperature, heat-preserved and liquefied for 45 minutes to obtain a high-boiling alcohol lignin depolymerization product;

[0040] (2) The above-mentioned lignin depolymerization products were extracted by solvent continuous extraction, that is, the above-mentioned lignin depolymerization products were continuously extracted with tetrahydrofuran at 50°C for 3 days, the solvent was separated, and then continuously extracted with acetonitrile at 90°C for 3 days, Finally, the extracted product is obtained.

[0041] By adjusting the depolymerization process and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com