A backsheet that can delay failure in alternating wet and dry environments

A dry-wet alternation and environment-friendly technology, applied in the direction of coating, polyester coating, polyurea/polyurethane coating, etc., can solve the problem of large backboard and achieve the effect of delaying failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

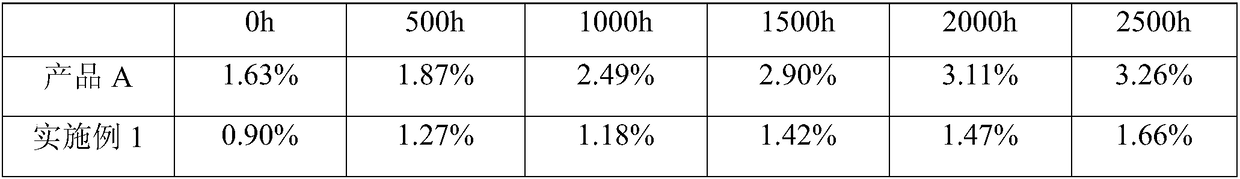

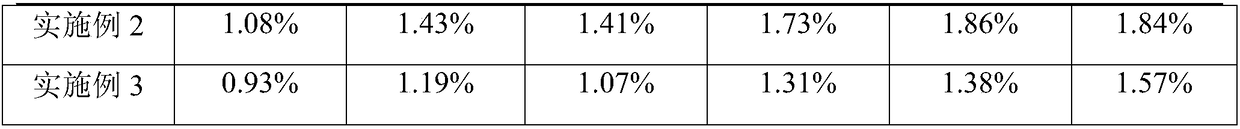

Embodiment 1

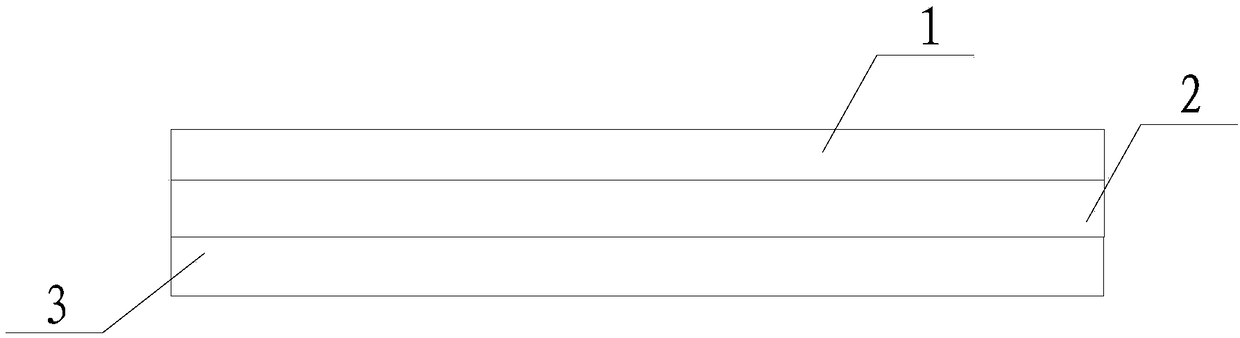

[0038] This embodiment provides a backsheet capable of delaying failure in an alternate wet and dry environment, such as figure 1 As shown, it includes an intermediate insulating layer 2, a first weather-resistant layer 1 formed on the upper surface of the intermediate insulating layer 2, and a second weather-resistant layer 3 formed on the lower surface of the intermediate insulating layer 2. The first weather-resistant layer 1 is made of organic silicon-fluorine The carbon interpenetrating network coating layer, and the second weather-resistant layer 3 is a fluorocarbon coating. The backboard is coated with corresponding coatings on both surfaces of the intermediate insulating layer 2 by means of spraying, dipping, roller coating, scraping, etc. It is cured by baking (ultraviolet or infrared, etc.) below ℃. The first weather-resistant layer 1 is a matte type, and the gloss is below 40; the second weather-resistant layer 3 is a high-gloss type, and the gloss is more than 70;...

Embodiment 2

[0041] This example provides a backsheet capable of delaying failure in alternating wet and dry environments, and its preparation method is consistent with that in Example 1, except that the raw materials for the silicone-fluorocarbon interpenetrating network coating layer include the following parts by weight Number of components: 60 parts of fluorine-containing resin, 5 parts of silicone prepolymer, 10 parts of polyester resin, 5 parts of inorganic filler, 1 part of auxiliary agent, 10 parts of diluent, 10 parts of isocyanate curing agent; fluorocarbon coating The raw materials include the following components in parts by weight: 55 parts of fluorine-containing resin, 10 parts of polyester resin, 5 parts of inorganic filler, 1 part of auxiliary agent, 10 parts of diluent, and 10 parts of isocyanate curing agent.

Embodiment 3

[0043] This example provides a backsheet capable of delaying failure in alternating wet and dry environments, and its preparation method is consistent with that in Example 1, except that the raw materials for the silicone-fluorocarbon interpenetrating network coating layer include the following parts by weight The number of components: 50 parts of fluorine-containing resin, 10 parts of silicone prepolymer, 20 parts of polyester resin, 15 parts of inorganic filler, 2 parts of auxiliary agent, 20 parts of diluent, 20 parts of isocyanate curing agent; fluorocarbon coating The raw materials include the following components in parts by weight: 50 parts of fluorine-containing resin, 20 parts of polyester resin, 15 parts of inorganic filler, 2 parts of auxiliary agent, 20 parts of diluent, and 20 parts of isocyanate curing agent. In this embodiment, the raw materials of the silicone-fluorocarbon interpenetrating network coating layer and the raw materials of the fluorocarbon coating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com