Air-lift type anaerobic bioreactor

An anaerobic biology and reactor technology, applied in bioreactor/fermenter combination, special-purpose bioreactor/fermenter, biochemical instrument, etc., can solve problems such as poor mixing degree, slow circulation, increased liquid viscosity, etc. , to achieve the effect of preventing dead angle and wide air intake position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

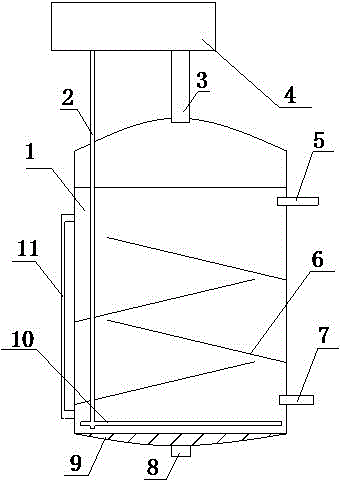

[0013] The airlift anaerobic bioreactor provided in this embodiment, such as figure 1 As shown, it includes: reaction tank body 1, air inlet pipe 2, gas injection pipe 10, separator 9 and circulating nitrogen tank 4; separator 9 is located at the bottom in the reaction tank body 1; the bottom of the reaction tank body 1 has a sewage outlet 8; The gas pipe 2 extends through the top of the reaction tank body 1 to the bottom of the reaction tank body 1; the gas injection pipe 10 is connected to the bottom end of the intake pipe 1; A number of air jets; the middle of the top of the reaction tank 1 has an exhaust port 3; the circulating nitrogen tank 3 is respectively connected to the intake pipe 2 and the exhaust port 3 to form a circulation pipeline, which is circulated under the drive of the motor. There are also several staggered baffles 6 inside the reaction tank 1; one side of the baffle 6 is fixedly connected to the reaction tank 1, and the side of the baffle 6 connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com