Wire cooling device

A cooling device, wire technology, applied in the direction of filament/wire forming, textile and papermaking, fiber processing, etc., to achieve the effect of suppressing time variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the yarn cooling device of the present invention will be described below.

[0026] [Melt spinning device]

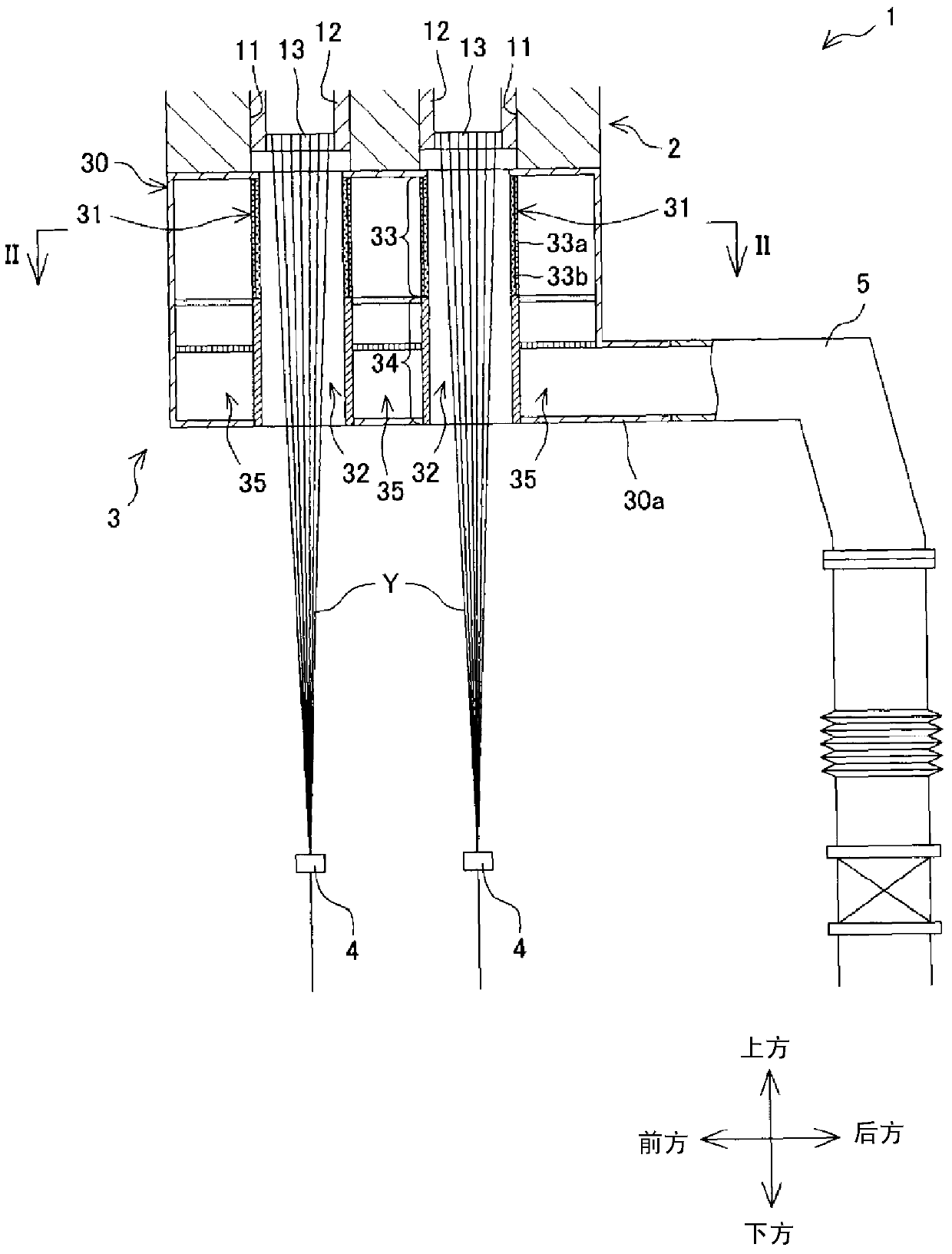

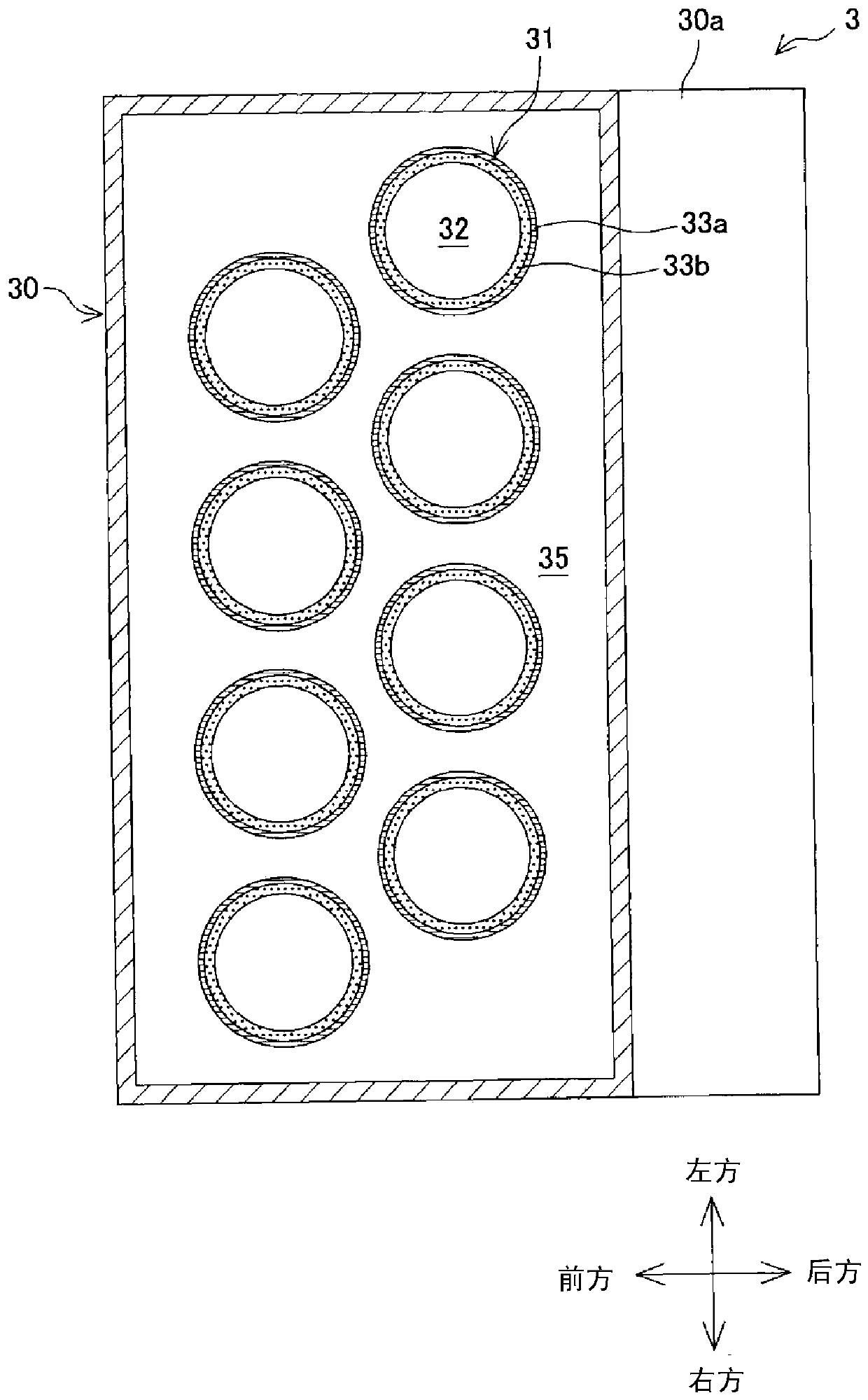

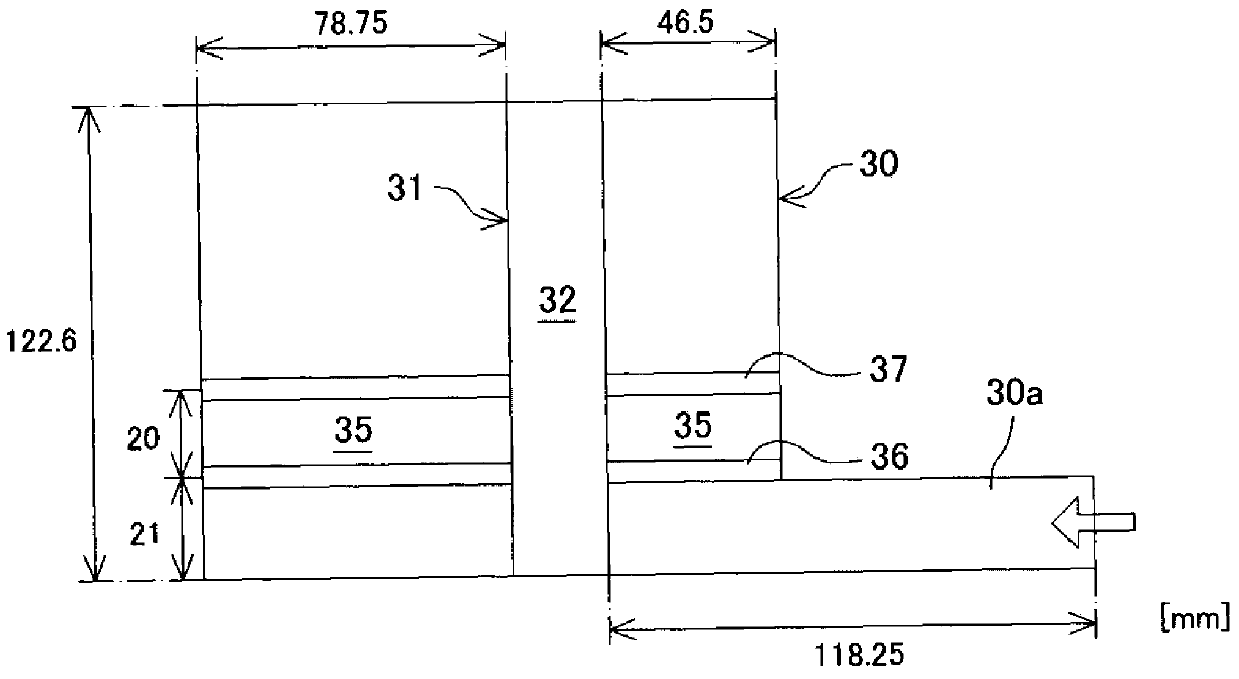

[0027] figure 1 It is a partial cross-sectional view of a melt spinning device equipped with a yarn cooling device of the present invention, figure 2 for figure 1 Ⅱ-Ⅱ line sectional view. Such as figure 1 As shown, the melt spinning device 1 includes a spinning beam 2, a yarn cooling device 3, an oil feeding device 4, and the like. The spinning beam 2 includes a plurality of unit housings 11 . In each pack case 11, a spin pack 12 is disposed, and in the spin pack 12 a melted material that becomes a yarn Y such as molten polyester is stored. A spinneret 13 is provided at the lower end of the spinneret 12, and the molten material stored in the spinneret 12 is spun out as a yarn Y from a plurality of through holes (not shown) formed in the spinneret 13. to the bottom. Among them, the plurality of spinnerets 13 are arranged in two rows in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com