Seepage failure simulation test device and construction method of embankment with upper defect

A technique for simulating experiments and constructing methods, which can be applied to hydraulic models, etc., and can solve problems such as unbalanced, difficult to reflect the evolution of seepage behavior and catastrophe process of dams with defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

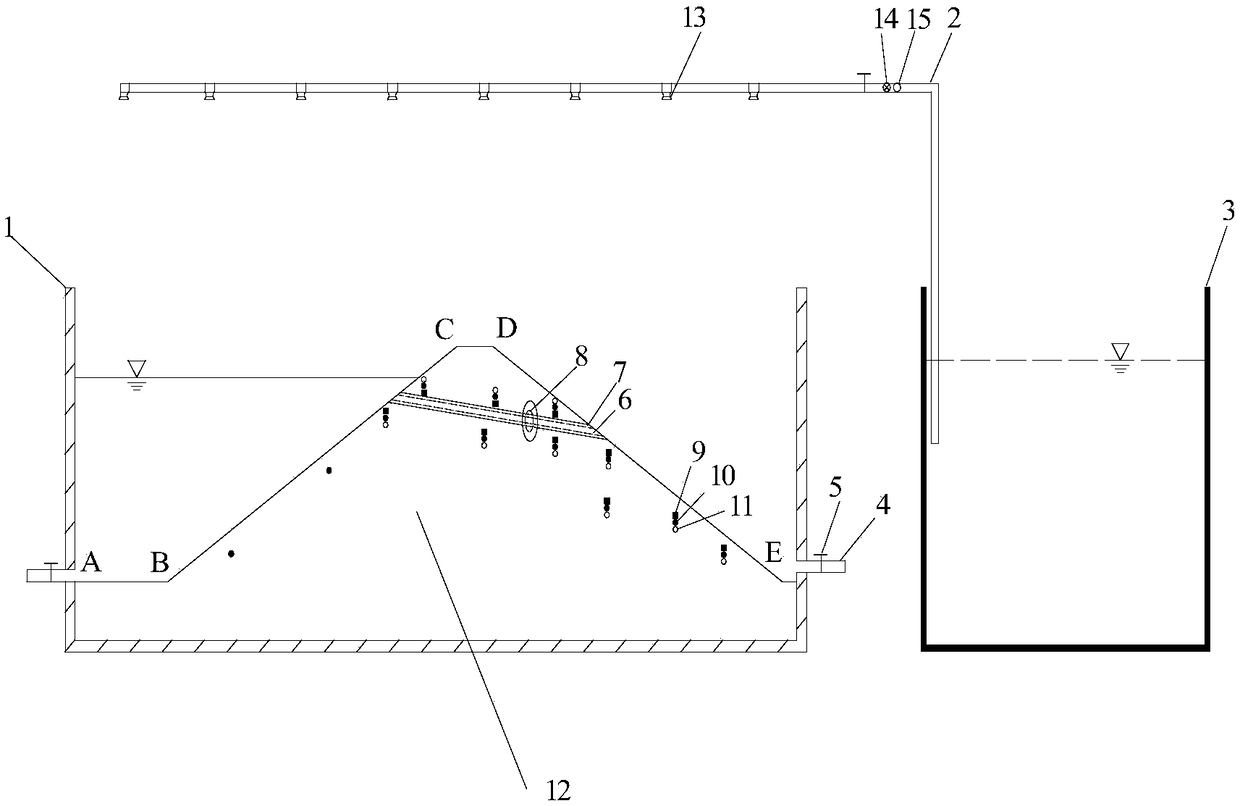

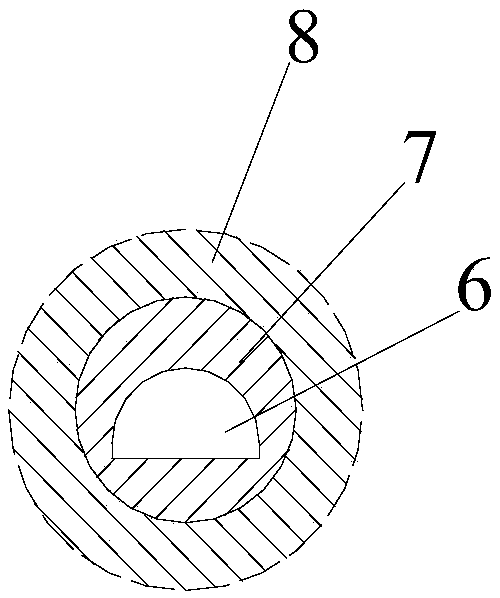

[0025] This embodiment relates to a simulation test device for the seepage failure of a dam containing upper defects, such as figure 1 with figure 2 As shown, the device includes a model tank 1 made of transparent plexiglass and a dyke model 12 set in the model tank 1 and made of a clay layer. The dyke model 12 and the dyke to be simulated are scaled down; the dyke model 12 includes successively Connecting the reservoir AB, the upstream dam slope BC, the dam crest CD, and the downstream dam slope DE, the upper part of the dyke model 12 is provided with a simulated antway 6 that penetrates the upstream dam slope CD and the downstream dam slope DE of the dam, and the dam model 12 is provided with a surrounding The weak area 7 of the simulated ant tunnel 6, the clay layer of the weak area 7 is looser the closer to the simulated ant tunnel 6; the cross-section of the simulated ant tunnel 6 is arched; the embankment model 12 is located near the simulated ant tunnel 6 at the downstre...

Embodiment 2

[0041] This embodiment is the construction method of the simulation test device for the seepage failure of the embankment containing the upper defect in the first embodiment. First, the clay is made into a soil sample, and the soil sample is used to fill the foundation of the embankment model in a model groove made of transparent plexiglass. After tamping the bottom and tamping, bury a thin tube with an arched cross section at a preset position on the upper part of the dyke model, the diameter of which is less than 10 cm, and the bottom width less than 8 cm; continue to fill the soil sample to a predetermined height of the thin tube, then ram it, and then dig Except the soil samples around the slim tube, expand the excavated area near the downstream dam slope to make the excavated area a spherical area, and refill the excavated soil samples, but reduce the number of compactions so that the clay layer in the spherical area is closer to the slim tube. After loosening, continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com