Straw set corn harvester

A harvesting platform and straw technology, which is applied in harvesting platforms, harvesters, agricultural machinery and implements, etc., can solve the problems of straw soil recovery, unfavorable soil protection and sustainable utilization, soil compaction and hardening, etc., so as to reduce ground pressure Land times, conducive to sustainable use, the effect of low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

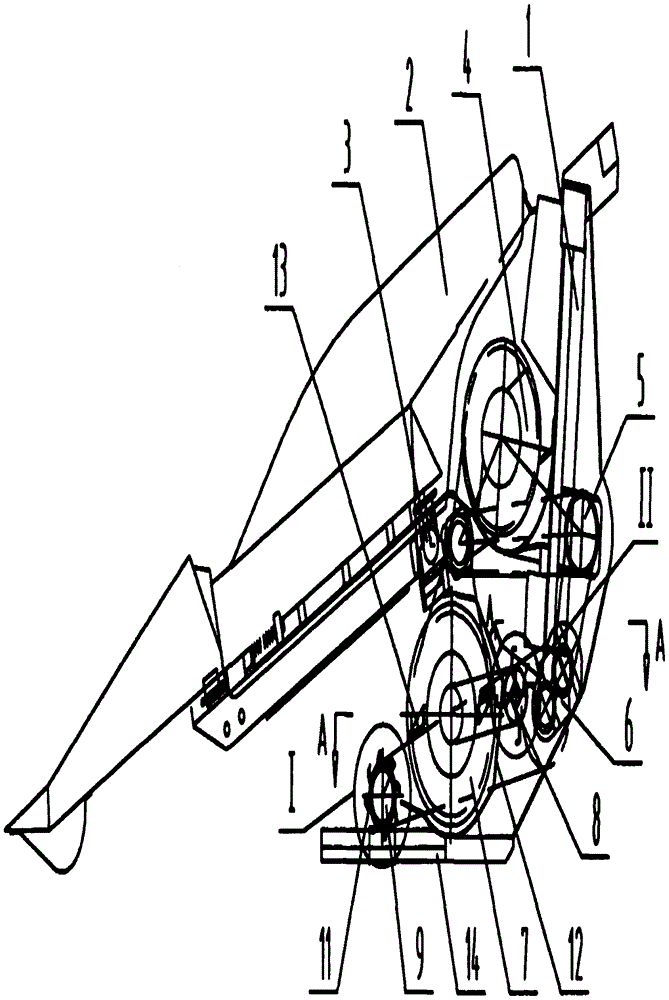

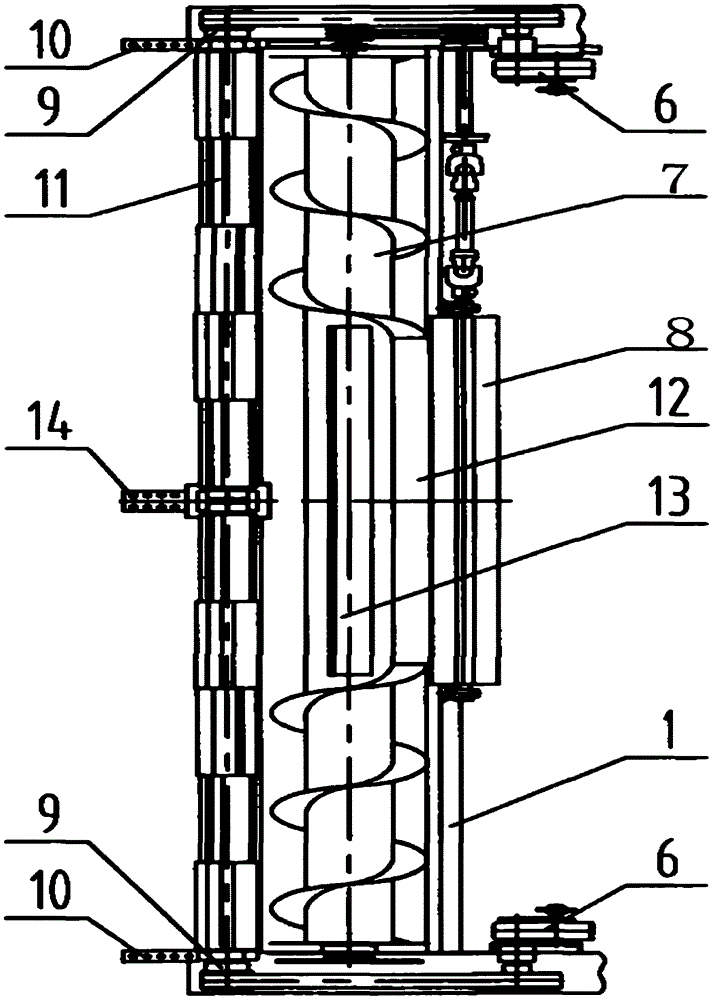

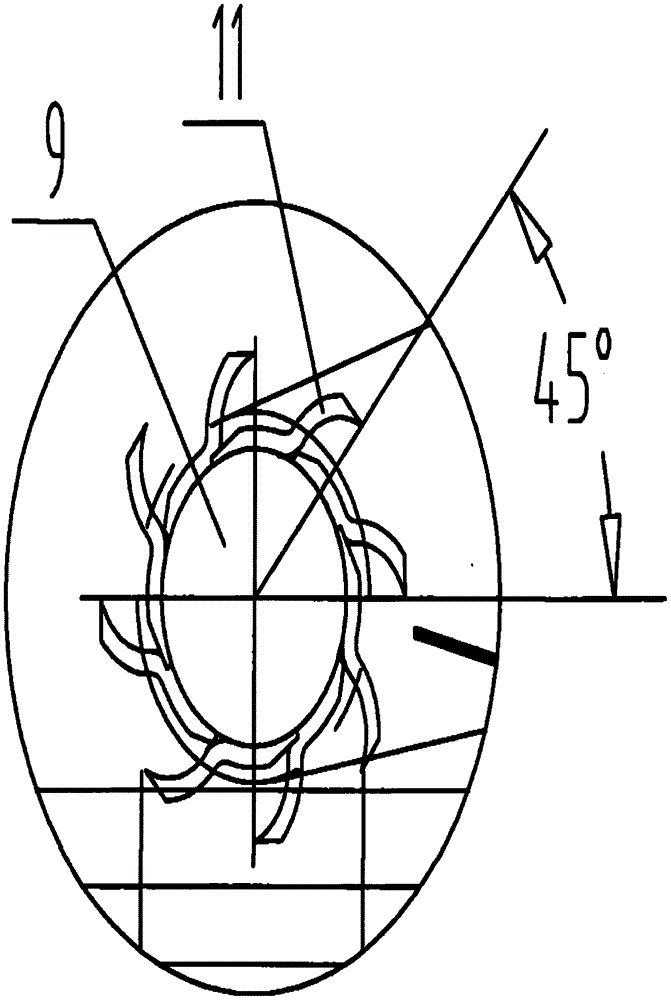

[0016] like figure 1 , figure 2 As shown, a schematic diagram of the structure of the stalk-collecting corn harvesting platform of the present invention is provided, including a frame 1 and a grain divider 2 installed on the frame 1, an ear picking device 3, an ear conveyor 4, and a transmission system 5 , and the stalk conveyor 7 arranged laterally on the rear and lower side of the ear picking device 3 , and below the front and lower side of the stalk conveyor 7 , a cutting and throwing device 9 is arranged parallel to the axis of rotation of the stalk conveyor 7 . The left and right side bottoms of the frame 1 are symmetrically provided with side bottom beams 10, the middle bottom of the frame 1 is provided with a middle bottom beam 14, and the two cutting and throwing devices 9 are arranged symmetrically on the left and right sides and rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com