Feeding equipment of bagged pellet material and use method

A granular material and equipment technology, applied in the direction of lifting devices, transportation and packaging, lifting frames, etc., can solve the problem of reducing the working efficiency of cranes and bag turning machines, not completely solving the damage of packaging bags, and the return of packaging bags is not profitable, etc. problems, to achieve the effect of simple structure, improved work efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

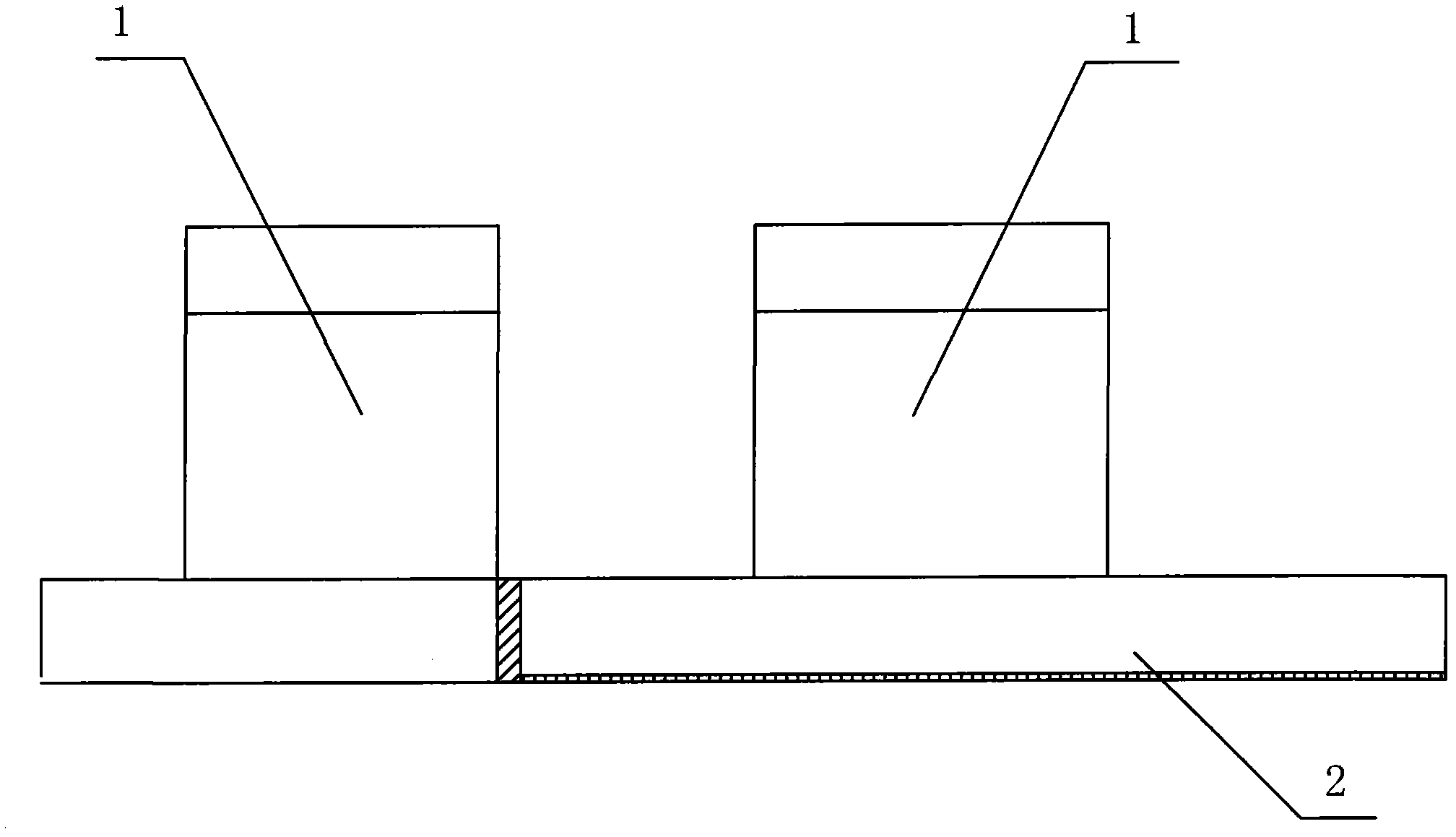

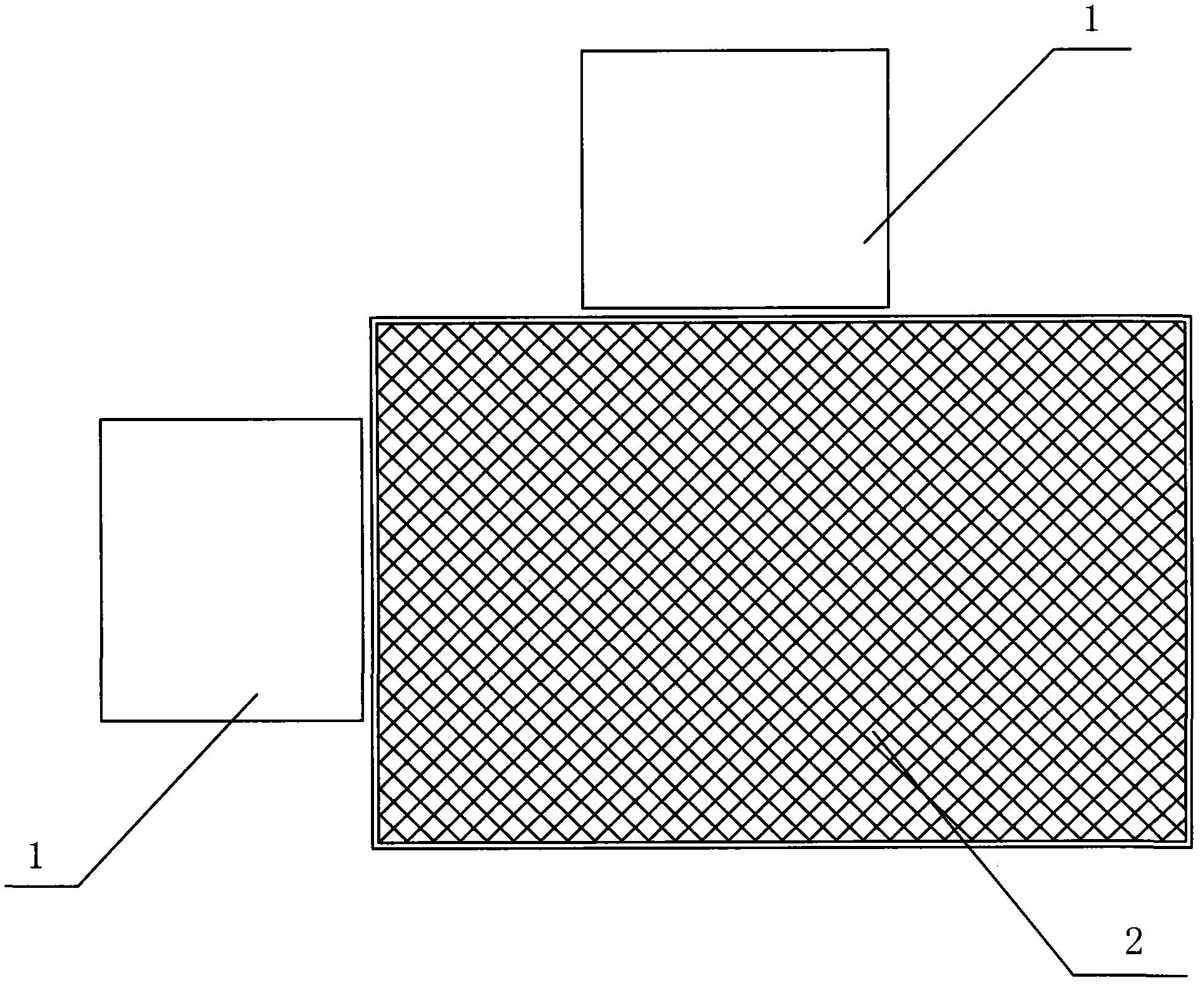

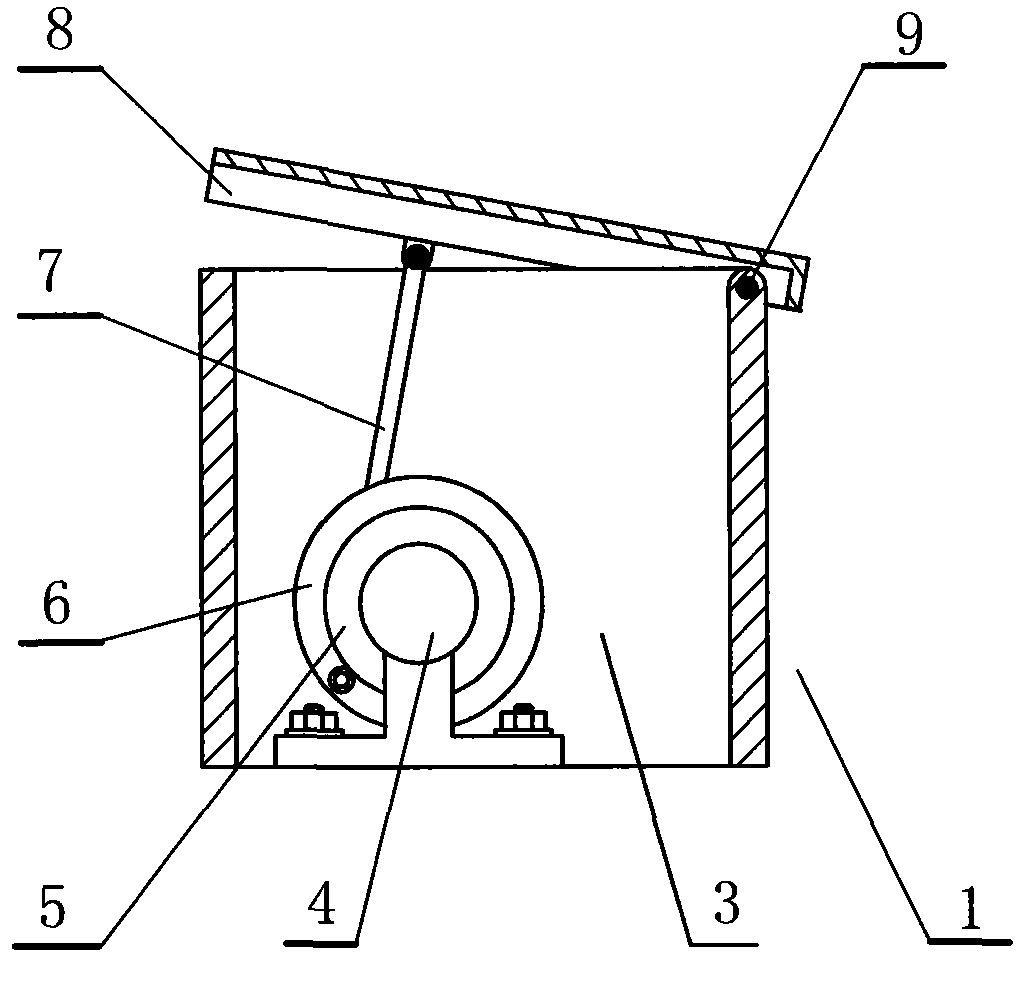

[0021] The first embodiment: as figure 1 , 2 As shown, bag turning machines (1) are installed on both sides of the material sieve (2) at the feeding part of the production line. should be equal, for a crane that can lift two bags of raw materials at a time, it is necessary to press figure 1 , 2 As shown, two bag turning machines (1) are equipped. combine image 3 , 4 , 5, it can be seen that this bag turning machine (1) has a box-shaped frame (3), and there are motor (4), gearbox (5), crank (6) and connecting rod (7) in the frame (3) ) and other institutions. The case lid above the frame (3) is a turnover plate (8), and the front bottom of the turnover panel (8) is hinged on the frame (3) by the turnover panel shaft (9). Connecting rod (7) upper end hinge is below turnover plate (8). When working, the raw material bag (16) is hoisted to the top of the flap (8) by the crane (15), and then the motor (4) is started, and the crank connecting rod (7) pushes the flap (8) aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com