Mulching film recycling machine

A technology of recycling machines and mulch, applied in collectors, agricultural machinery and tools, agriculture, etc., can solve problems such as unfavorable crop growth, soil pollution and damage, and maintain soil structure in the later stage, so as to facilitate planting and growth and avoid pollution , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

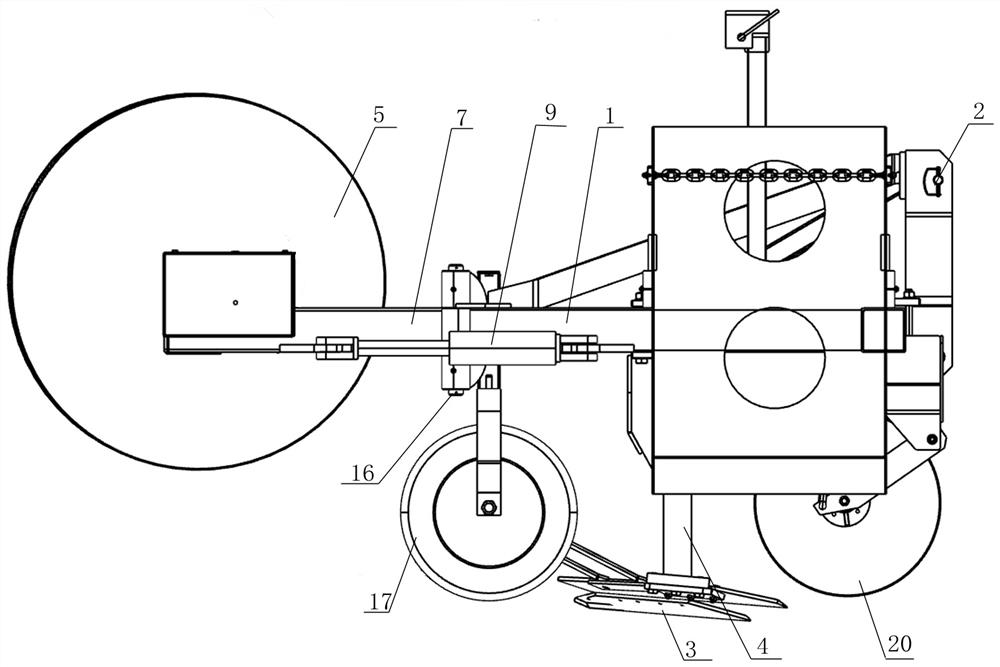

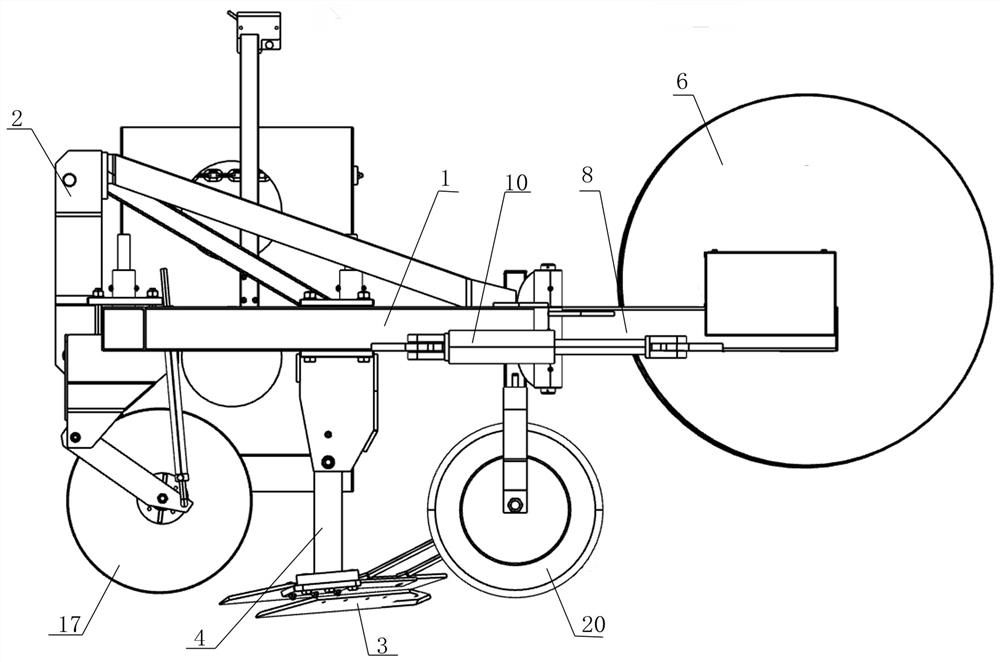

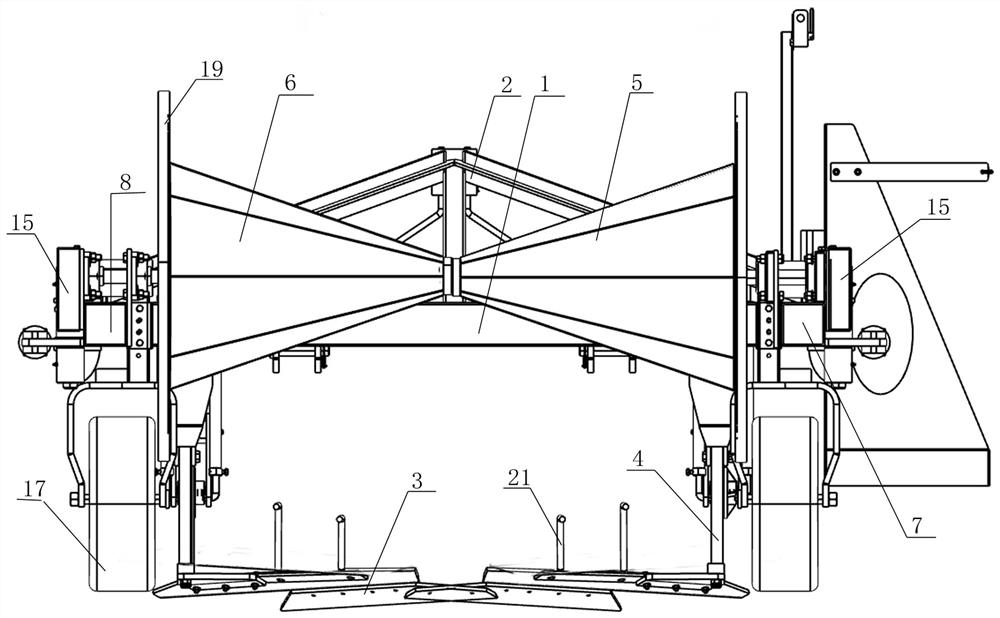

[0029] Such as Figure 1 to Figure 6 As shown, the front view, rear view, left view, right view, top view and perspective view of the mulching film recycling machine of the present invention are provided respectively, Figure 7 and Figure 8 Both provide the three-dimensional view of the mulch recovery machine of the present invention, the mulch recovery machine shown is composed of a frame 1, a suspension seat 2, a walking wheel 17, a mulch scooping mechanism and a mulch automatic winding mechanism, and the frame 1 is fixed and supported Function, the suspension seat 2 is fixed on the frame 1, and the suspension seat 2 is used to be connected with the traction machinery. Both sides below the frame 1 are provided with traveling wheels 17, and the rotation of the traveling wheels 17 is used to realize the walking of the whole plastic film recovery mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com