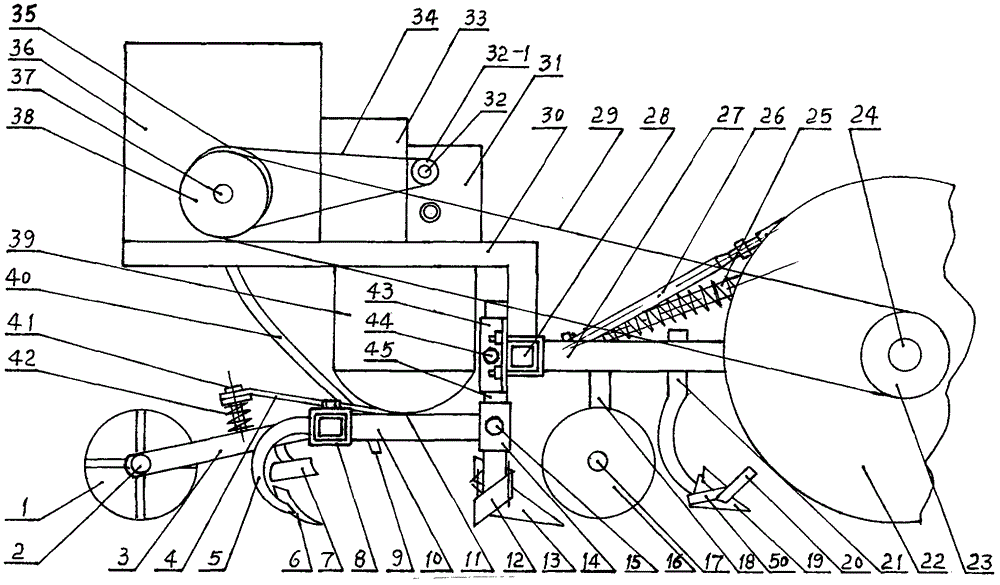

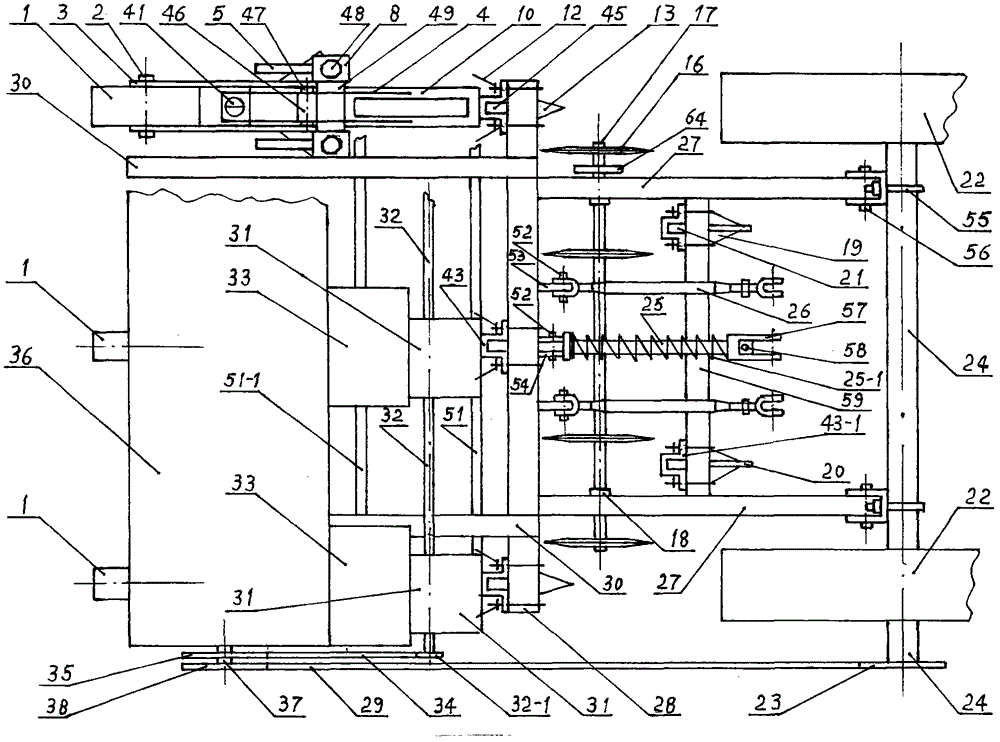

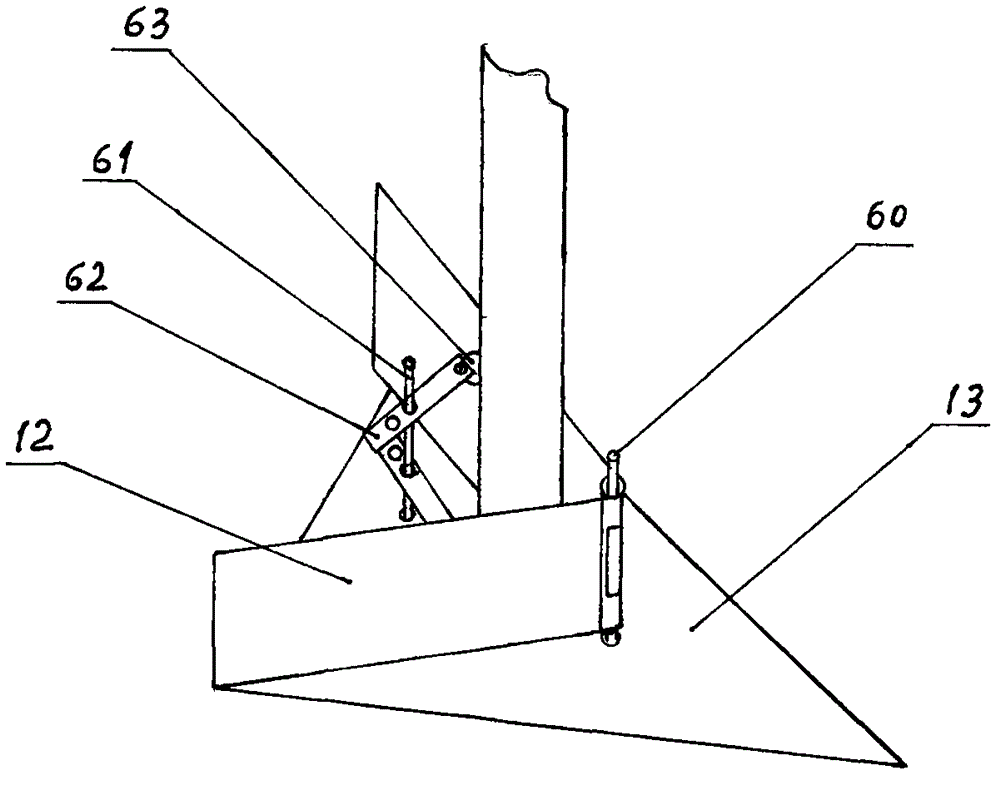

Water-saving ditch seeding method and stubble-returning multi-process tiller-seeder using same

A multi-process, furrowing technology, applied to agricultural machinery and implements, shovels, plows, etc., can solve problems that affect aviation, road traffic safety, decrease in soil organic matter content, air pollution, etc., to achieve the benefit of crop growth and root development , agricultural cost reduction, and the effect of less turning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In Fengshou Town, Da’an City, Jilin Province, during the spring sowing season with windy sand and drought, in the mung bean field that had not been stubble-removed in the previous season, stubble removal, rotary plowing and land preparation were not performed, and new ridges were not raised; Combination of procedures The cultivator and seeder plant corn, and the following procedures are completed at one time: shallow ditch division and stubble breaking are carried out on the ridges of the previous season, so that the ridges of the previous season can reach the level of tractor wheels during intertillage; at the same time, the stalks of the previous season Cut into small sections, and then cover the small sections of last season's stubble stalks and the roots of the stubble and broken stubble, and then plow, sow, fertilize, cover soil, and suppress in the furrows of the previous season. The yield of corn harvested in autumn is about 30% higher than that of traditional rid...

Embodiment 2

[0022]In Fengshou Town, Da’an City, Jilin Province, during the spring sowing season when the spring is windy and sandy and dry, in the corn field that has not been cut in the previous season, the straw is not cut, the stubble is not removed, the rotary tillage is not prepared, and the new ridges are not raised; the stubble of the present invention is used. The stalk returning to the field multi-process combination cultivator and seeder planting sorghum can complete the following processes at one time: divide and break the stubble by shallow furrows on the ridges of the previous season, so that the ridges of the previous season can reach the level of tractor wheels during intertillage; The stubble of the season is cut into small sections, and then the small section of the stubble of the previous season and the roots of the stubble and the broken stubble are covered with soil, and then the furrows of the previous season are plowed, sowed, fertilized, covered with soil, and suppres...

Embodiment 3

[0024] In Fengshou Town, Da’an City, Jilin Province, in the spring sowing season when the spring is windy and sandy and dry, in the corn field that has not been stubble-removed in the previous season, stubble removal, rotary plowing, and new ridges are not performed; Combination of working procedures The cultivator and seeder plant mung beans, and complete the following procedures at one time: shallow ditch division and stubble breaking on the ridges of the previous season, so that the ridges of the previous season can reach the level of tractor wheels during intertillage; at the same time, the stalks of the previous season Cut into small sections, and then cover the small sections of last season's stubble stalks and the roots and hairs that have been divided and broken, and then plow, sow, fertilize, cover soil, and suppress in the last season's furrows. The output of mung bean harvested in autumn is about 15% higher than that of traditional ridge planting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com