An eps composite thermal insulation roof

A composite thermal insulation and thermal insulation board technology, applied in the direction of roof, roof covering, building roof, etc., can solve the problems of poor thermal insulation effect, high maintenance cost, complicated installation, etc. effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

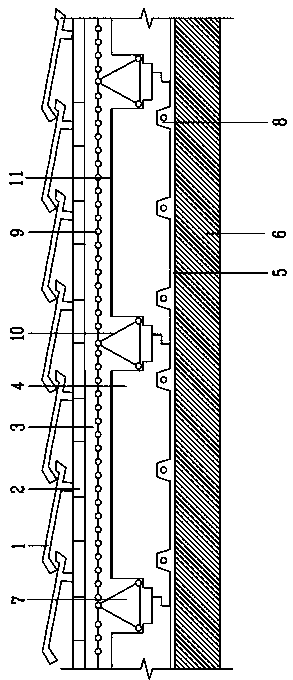

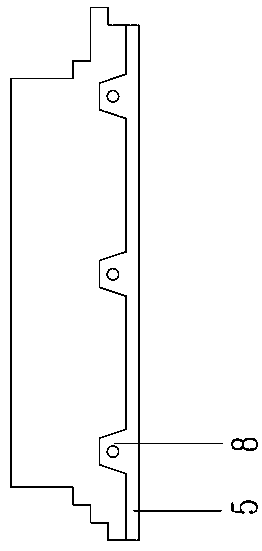

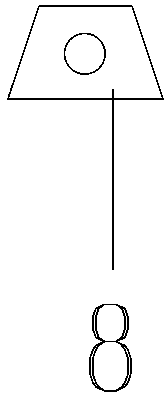

[0022] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: as figure 1 , figure 2 with image 3 Shown is an EPS composite thermal insulation roof, which includes a roof tile layer 1, a waterproof mortar protection layer 2, a cast-in-place concrete layer 3, a mixed layer 11 composed of EPS insulation boards 4 and cement boards 5 from top to bottom, The square steel supports the purlin 6, and the two ends of a single EPS insulation board 4 are provided with a half notch, and the two half notches of two adjacent EPS insulation boards 4 are connected to form a complete notch, and in the notch is Concrete rib beams 7 in an integrated structure are poured simultaneously with the cast-in-place concrete layer 3, the contact surfaces of the two EPS insulation boards 4 below the notch are bonded by foam glue, and the mixed layer 11 is formed by the EPS insulation board 4 It is prefabricated by bonding with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com