Focused shock wave excitation device for dynamic feature testing of microstructure of MEMS (micro-electromechanical system)

A technology of excitation device and dynamic characteristics, which is applied in the field of focused shock wave excitation device, can solve problems such as the difficulty of microstructure dynamic characteristic parameters, and achieve the effects of good excitation effect, concentrated energy, and easy testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

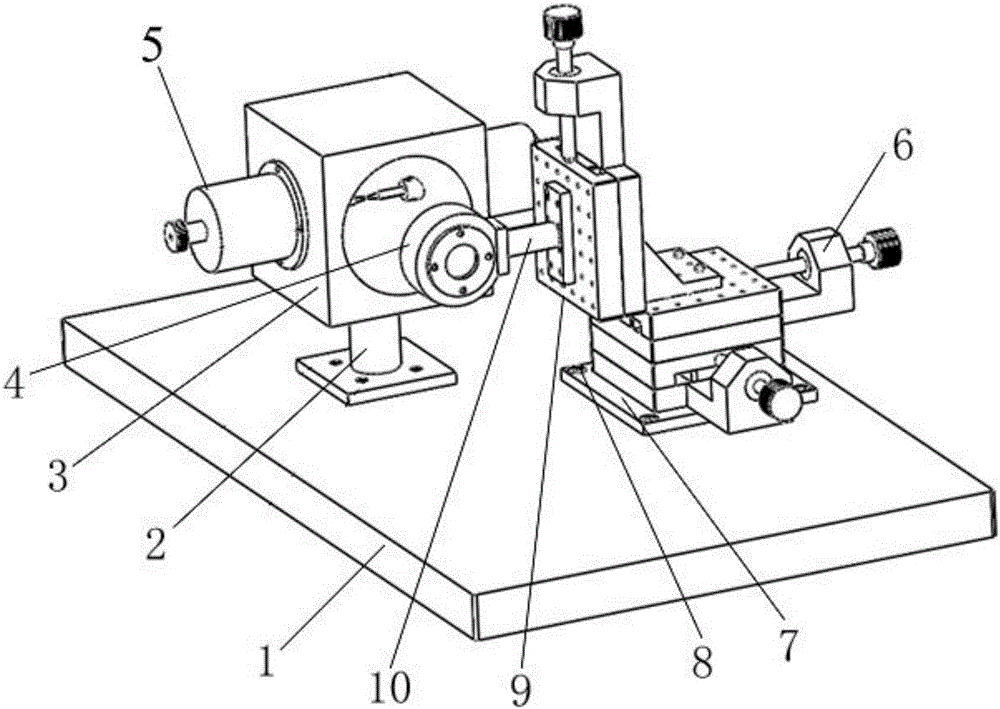

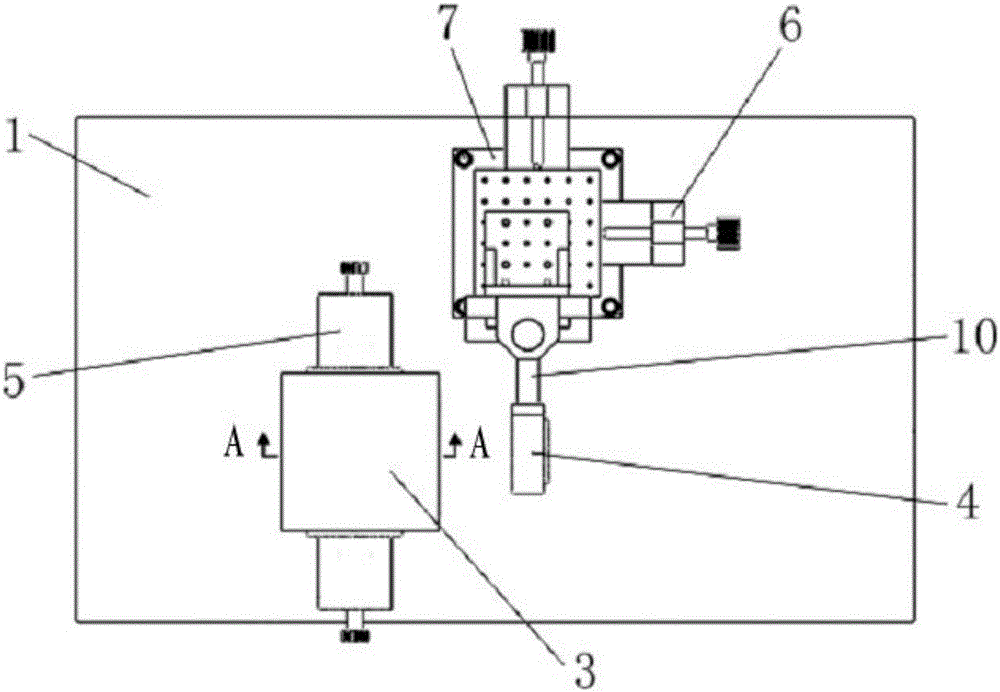

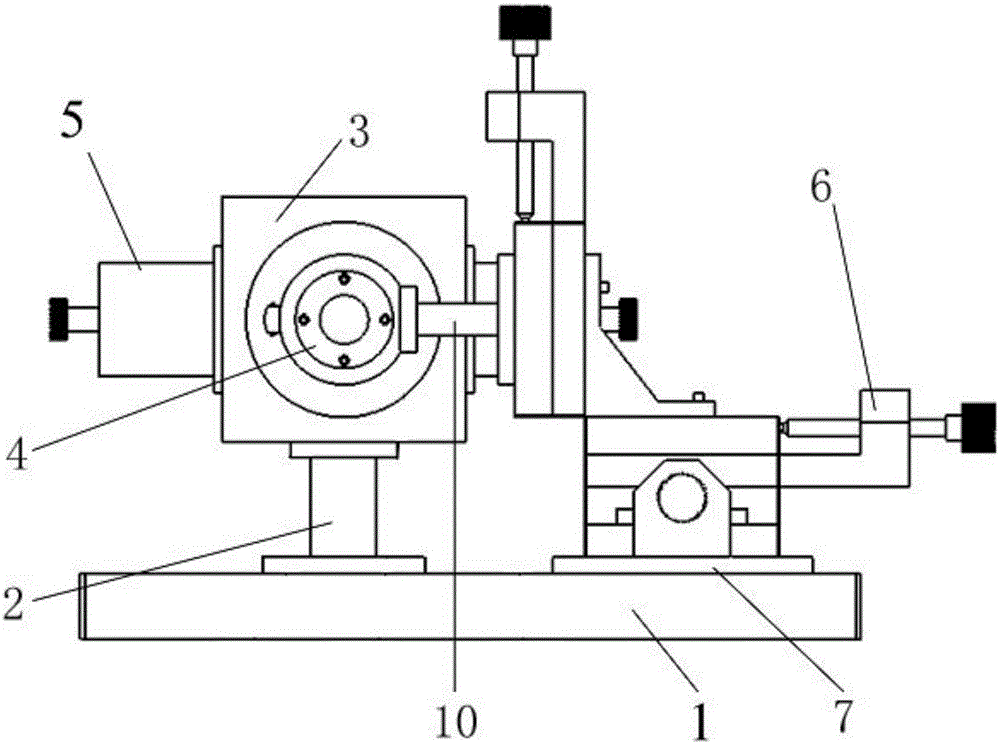

[0026] like Figure 1-Figure 3 As shown, the present invention relates to a focused shock wave excitation device for testing the dynamic characteristics of MEMS microstructures, comprising a substrate 1, and a manual three-axis displacement stage 6 and a support 2 are arranged on the substrate 1. The manual three-axis The displacement stage 6 is mounted on a base plate 7 , and the base plate 7 is fixed on the base plate 1 by screws 8 . A microstructure unit 4 is provided on the Z-axis slide 9 of the manual three-axis displacement stage 6;

[0027] like Figure 7-Figure 9 As shown, the micro-structure unit 4 includes a mounting sleeve 401 which is mounted on the Z-axis slide 9 through the horizontal support 10. The mounting sleeve 401 is provided with a stepped mounting hole. The MEMS microstructure 405 is installed on the structure mounting plate 407; the microstructure mounting plate 407 is fixed on the annular plane at the bottom of the mounting hole through the screws 406...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com