Automotive Micro Motor Housing

A micro-motor and casing technology, applied in the direction of casing/housing/support, electromechanical devices, electrical components, etc., can solve the problem of reducing the axial matching length of the bearing chamber, low processing efficiency, and difficulty in achieving the alignment of the center axis of the end cover. Axis requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

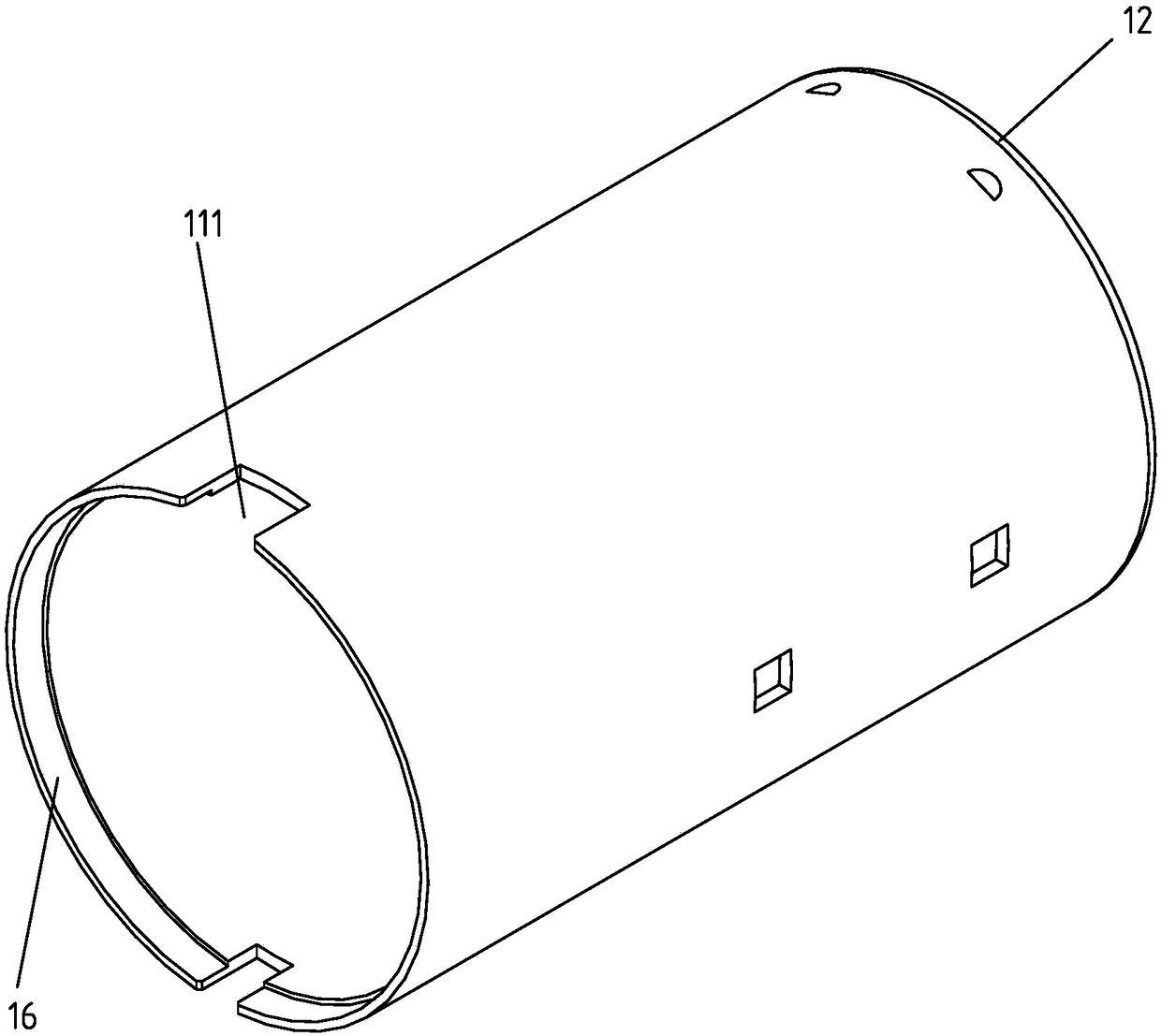

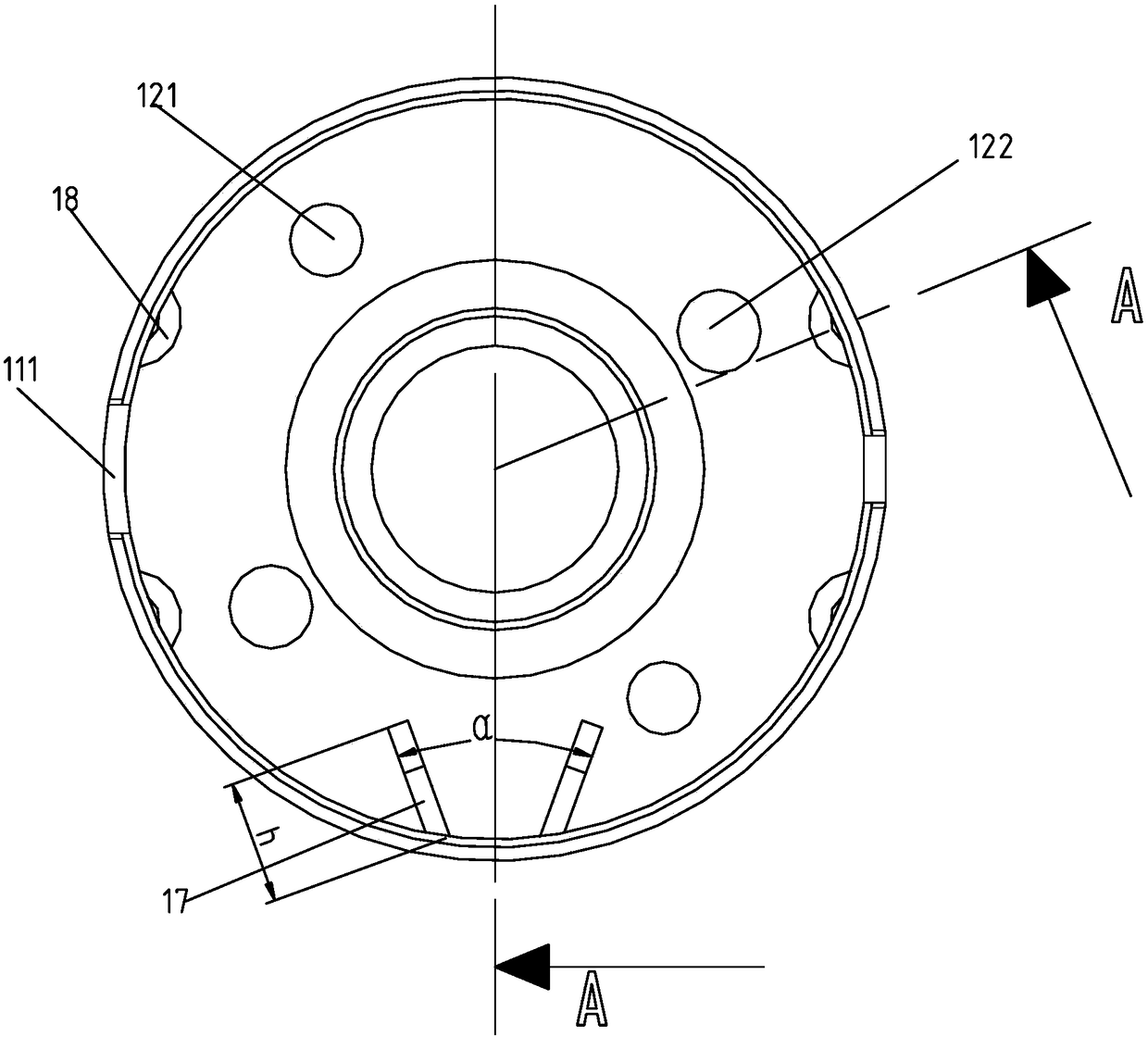

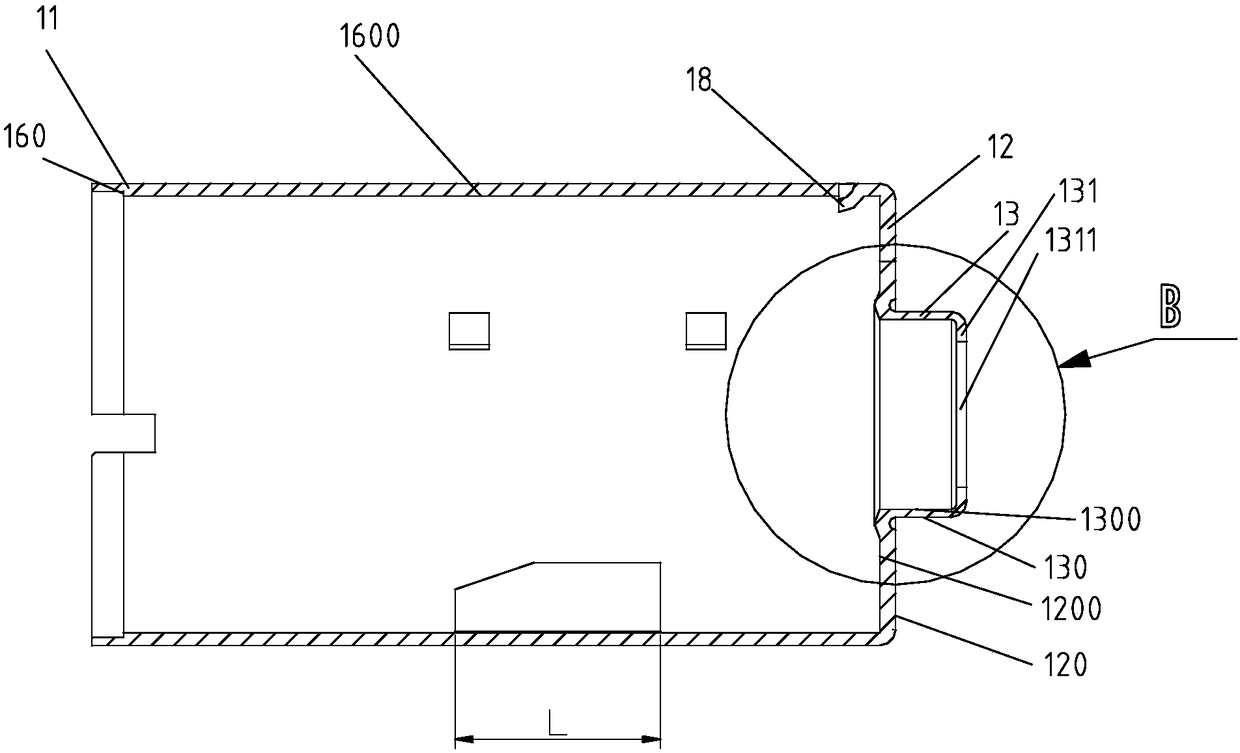

[0026] Such as Figure 1-8 Shown, a kind of automobile micro-motor casing, it comprises:

[0027] The casing, which is made of a generally hollow cylindrical casing with a bottom by punching, punching, stretching, and stamping a thin steel plate for many times, and one end of the casing is an open end 11. The other end of the casing is formed with a cylinder bottom 12, and the casing bottom 12 is provided with a casing bearing chamber 13 protruding axially outward and accommodating bearings. The casing is provided with a The notch part 16 coaxial with the rotary shaft of the casing, the axially outer end of the casing bearing chamber 13 is provided with a first fixing part 131 for fixing the axial end of the bearing, and the first fixing part 131...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com