High-overlying-coefficient stator iron core preparation method and stator iron core

A technology of stator core and lamination coefficient, which is applied in the field of motor components, can solve problems such as small lamination coefficient, increased alternating magnetic flux loss, and short circumferential length of stator core, so as to improve lamination coefficient, shaft The effect of increasing the effective length and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

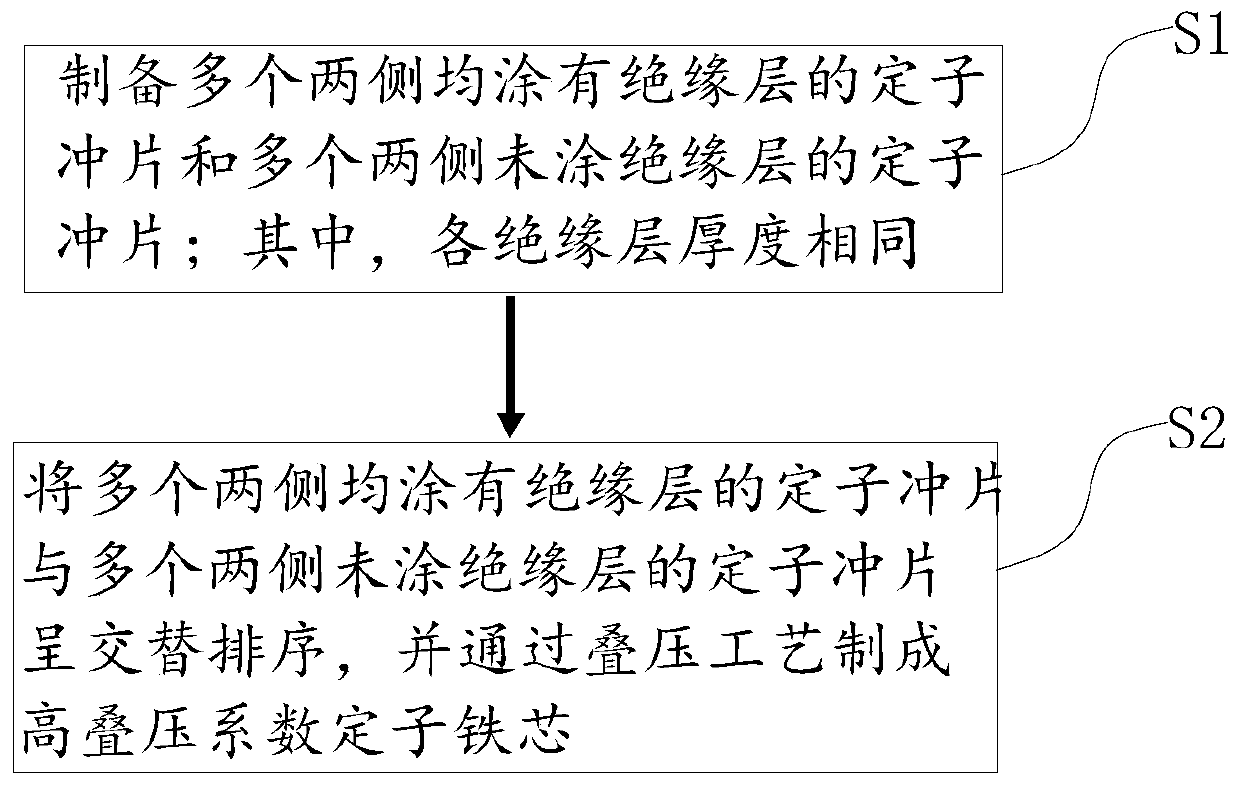

[0032] Such as figure 1 As shown, this embodiment provides a method for preparing a stator core with a high lamination factor, including the following steps:

[0033] S1) Prepare a plurality of stator punches with insulation layers coated on both sides and a plurality of stator punches with no insulation layers on both sides; wherein, the thickness of each insulation layer is the same;

[0034] S2) A plurality of stator punches coated with insulating layers on both sides and a plurality of stator punches not coated with insulation layers are arranged alternately, and a stator core with a high lamination coefficient is manufactured through a lamination process.

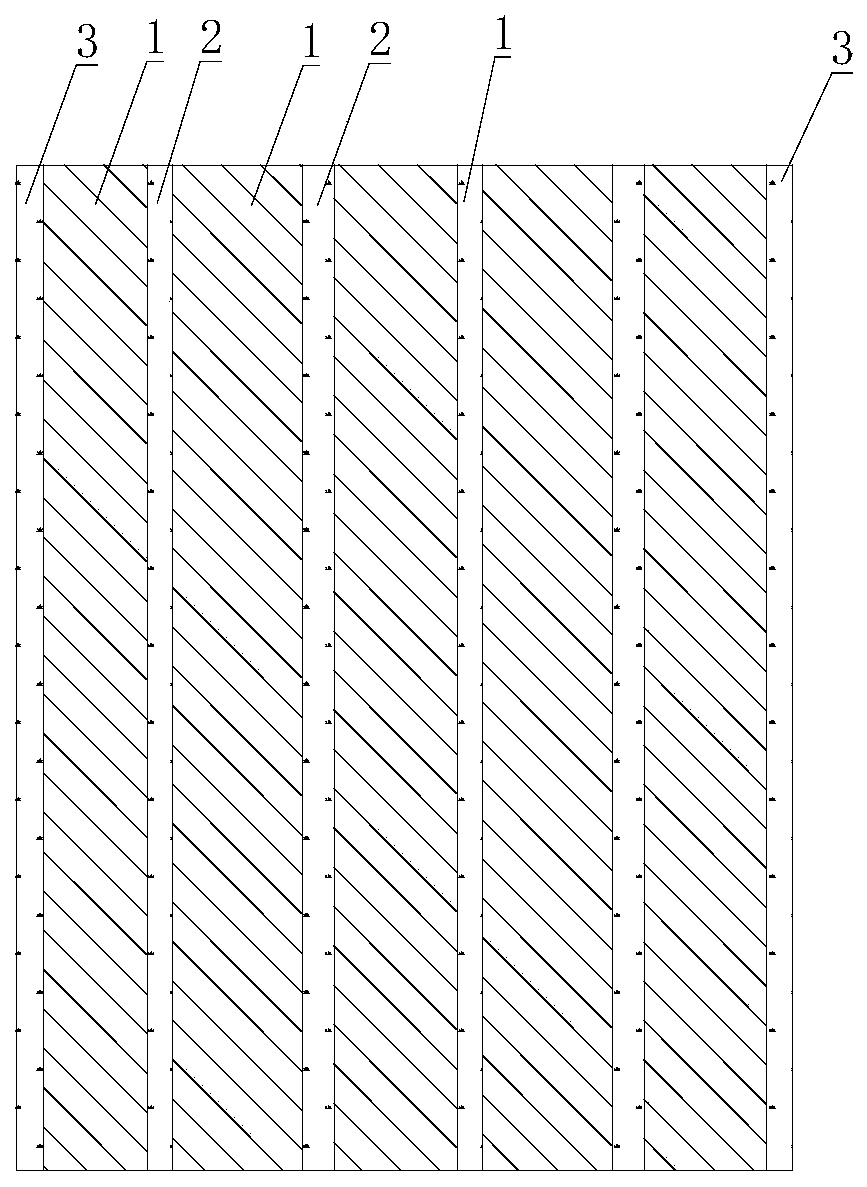

[0035] Specifically, the material of the stator punching sheet is silicon steel, which is prepared by silicon steel sheet; the thickness of the insulating layer is 0.005mm-0.015mm, and the thickness of the insulating layer is preferably 0.01mm in this embodiment to ensure the insulating performance; the material of the...

Embodiment 2

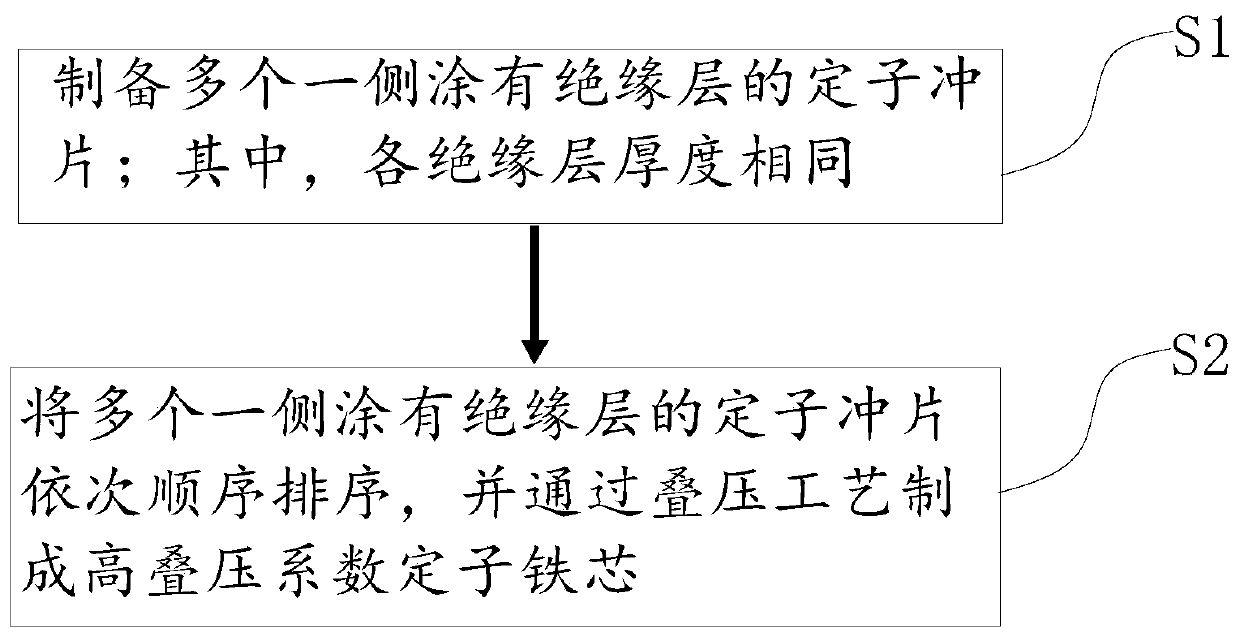

[0043] The invention provides a method for preparing a stator core with a high lamination coefficient, comprising the following steps:

[0044] S101) preparing a plurality of stator punches coated with an insulating layer on one side; wherein, each insulating layer has the same thickness;

[0045] S102) Sequentially sorting a plurality of stator stamping sheets coated with an insulating layer on one side, and manufacturing a stator core with a high lamination coefficient through a lamination process.

[0046] Specifically, the material of the stator punching sheet is silicon steel; the thickness of the insulating layer is 0.005mm-0.015mm, and the preferred thickness of the insulating layer in this embodiment is 0.01mm to ensure the insulation performance; the material of the insulating layer includes phosphoric acid-chromic acid paint, resin - At least one of chromic acid-based paint or insulating glue. In this embodiment, the phosphoric-chromic acid-based paint is preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com