Single-component aqueous silicon steel sheet paint

A silicon steel sheet paint, one-component technology, used in coatings, epoxy resin coatings, etc., can solve the problems of inconvenience on the construction site, small lamination coefficient of iron cores, poor stability, etc., to improve adhesion or bonding performance. , to avoid measurement errors, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

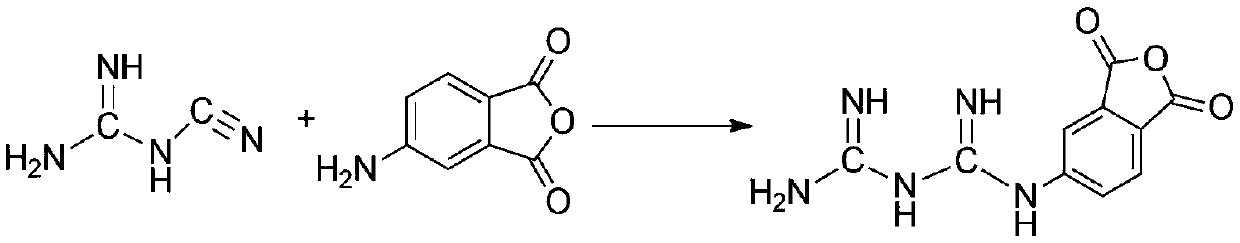

Method used

Image

Examples

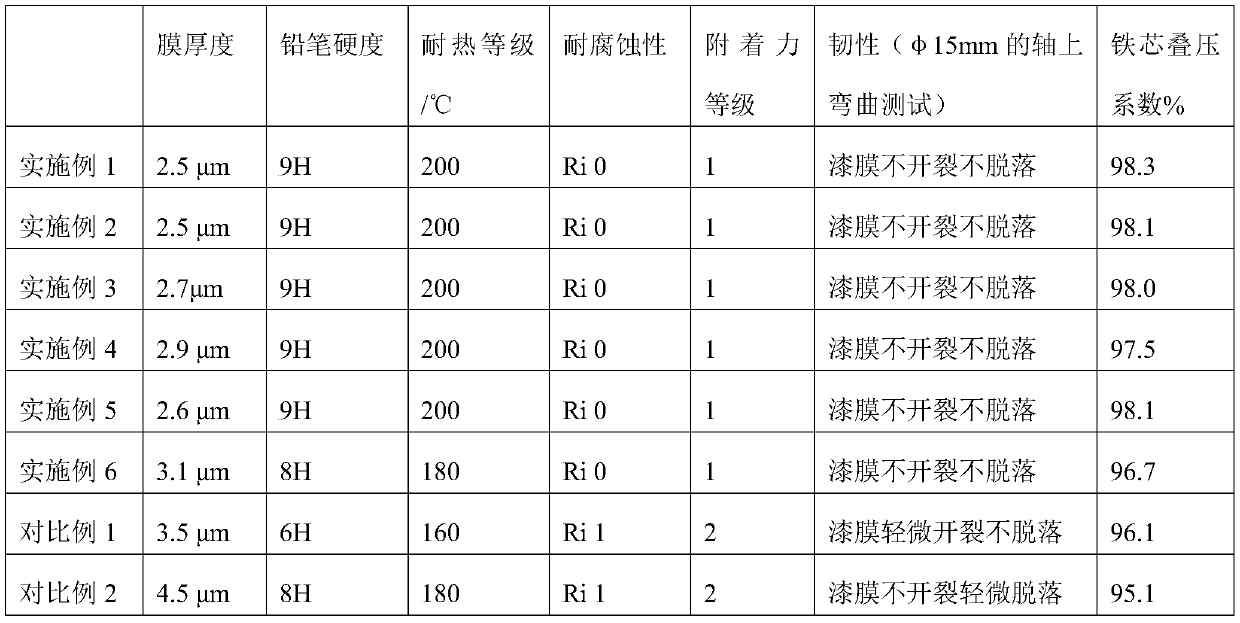

Embodiment 1

[0042] Weigh 80.0g water; 5.2g modified dicyandiamide; 1.0g morpholine-4-methylbenzenesulfonate; 260g epoxy resin Waterpoxy1422; 20g diluent 1,4-butanediol diglycidyl ether, 15g Diluent benzyl glycidyl ether; 7g nano-silica, 5g nano-tin dioxide; 0.8g ethylene glycol mixed with 2.5g 1-(2-butoxyethoxy)ethanol as wetting agent; 0.6g defoaming agent Agent B-0520; 1.0g leveling agent ethyl acetoacetate; 0.5g preservative KATHON LXE; 1.8g anti-flash rust agent R-760F; 10g Dow Corning silane coupling agent Z-6011; 0.3g neutralizing agent dimethyl Ethanolamine DMEA.

[0043] Add modified dicyandiamide, morpholine-4-methylbenzenesulfonate, water-based epoxy emulsion, wetting agent, defoamer, preservative, leveling agent and anti-flash rust agent to the reaction kettle in sequence Stir at medium and high speed (about 5000r / min) for 5 hours, stir at low speed and add silane coupling agent and neutralizing agent, stir well and set aside. Inorganic filler nano-silica SiO 2 and nano-tin ...

Embodiment 2

[0045]Weigh 100g water; 10g curing agent modified dicyandiamide; 1.0g morpholine-4-methylbenzenesulfonate; 200g epoxy resin Waterpoxy1422; 15g diluent 1,4-butanediol diglycidyl ether, 15g Diluent benzyl glycidyl ether; 7g nano-silica, 10g nano-tin dioxide; 1.8g 2-(2-butoxyethoxy)ethanol and 2.5g 1-(2-butoxyethoxy) Ethanol mixed as a wetting agent; 0.5g defoamer B-0519; 2.0g leveling agent 4-chloroacetoacetate ethyl ester; 0.7g preservative KATHON LXE; 2.0g anti-flash rust agent R-760F; 10g Dow Corning silane Joint agent Z-6121; 1.4g neutralizing agent dimethylethanolamine DMEA.

[0046] Add modified dicyandiamide, morpholine-4-methylbenzenesulfonate, water-based epoxy emulsion, wetting agent, defoamer, preservative, leveling agent and anti-flash rust agent to the reaction kettle in sequence Stir at medium and high speed (about 5000r / min) for 5 hours, stir at low speed and add silane coupling agent and neutralizing agent, stir well and set aside. Inorganic filler nano-silica ...

Embodiment 3

[0048] Weigh 120g water; 15g curing agent modified dicyandiamide; 1.5g morpholine-4-methylbenzenesulfonate; 300g epoxy resin Waterpoxy1455; 10g diluent 1,4-butanediol diglycidyl ether, 30g Diluent benzyl glycidyl ether; 10g nano-silica, 10g nano-tin dioxide; 2.5g propylene glycol and 2.5g 1-methoxy-2-propanol mixed as wetting agent; 1.0g defoamer B-0518 ; 1.0g leveling agent ethyl acetoacetate, 1.0g methyl 4-chloroacetoacetate; 1.0g preservative KATHONLXE; 2.8g anti-flash rust agent R-760F; 20g Dow Corning silane coupling agent Z-6020; 2.6g medium And the agent dimethylethanolamine DMEA.

[0049] Add modified dicyandiamide, morpholine-4-methylbenzenesulfonate, water-based epoxy emulsion, wetting agent, defoamer, preservative, leveling agent and anti-flash rust agent to the reaction kettle in sequence Stir at medium and high speed (about 5000r / min) for 5 hours, stir at low speed and add silane coupling agent and neutralizing agent, stir well and set aside. Inorganic filler na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com