Manufacturing method of segment core, segment core and iron core manufactured by using method

A core and punching technology, applied in the field of motors, can solve the problems affecting the lamination coefficient and lamination quality, the lamination coefficient is difficult to achieve, and the lamination coefficient is difficult to achieve, so as to ensure the lamination coefficient and lamination quality, high The effect of overlapping coefficient and reducing the difficulty of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

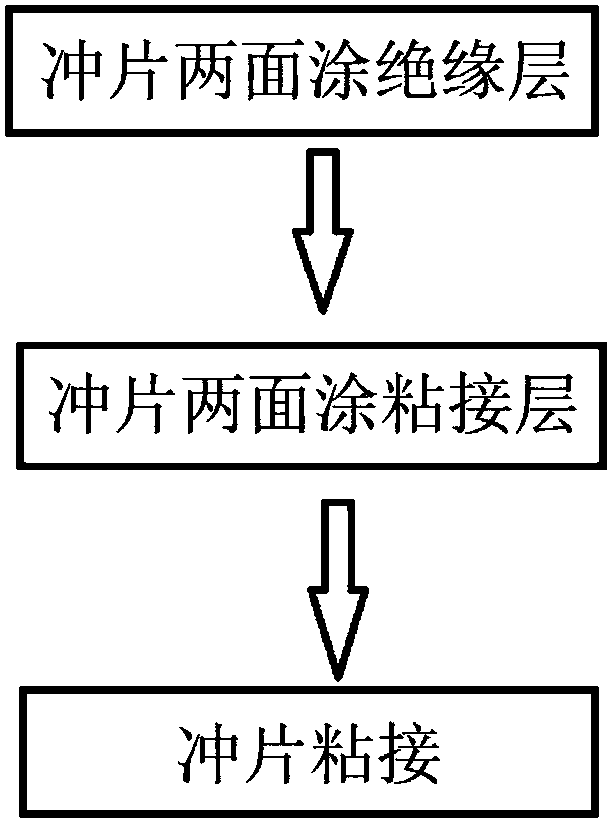

[0038] One embodiment of the present invention provides a method for manufacturing a segmented core, the method comprising the following steps:

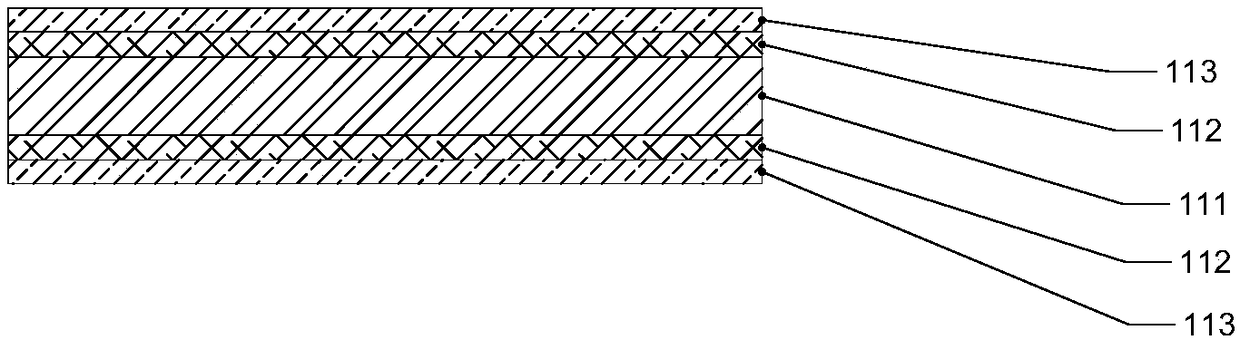

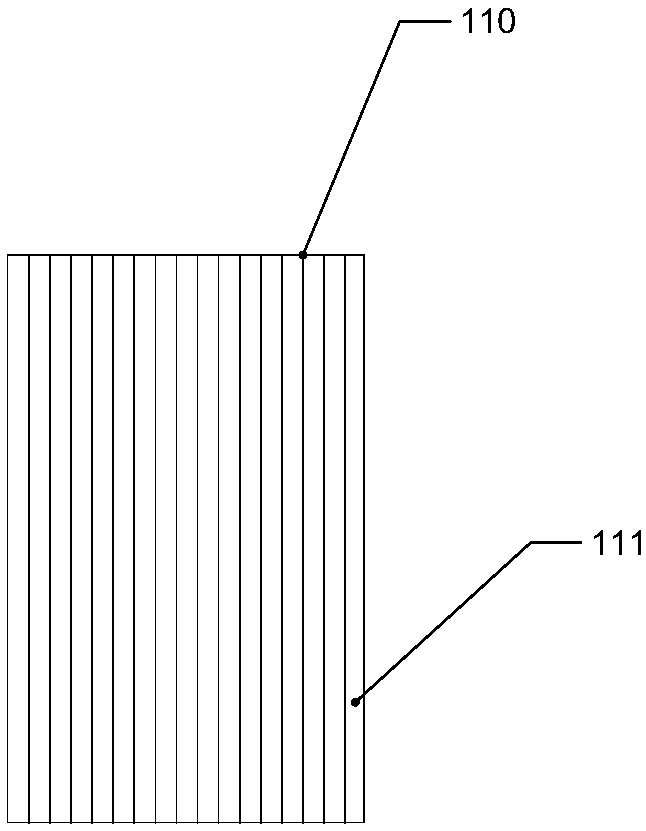

[0039] first step, such as figure 1 As shown, at first the two sides of punching sheet 111 are coated with insulating layer 112 respectively, and its thickness is 25-40um, and the effect of insulating layer 112 is to increase the resistance of iron core, reduce the eddy current (circulating current) loss of iron core under the action of alternating magnetic flux, Prevent the iron core from heating and partially melting, commonly known as the iron core "fire". The stamped sheet can be a silicon steel sheet, and the thinner the silicon steel sheet, the smaller the eddy current loss. At present, there are two commonly used insulating coatings: one is phosphoric acid-chromic acid coating, the coating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com