Novel permanent magnet motor stator iron core

A permanent magnet motor and stator core technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of increasing the cost of motor manufacturing materials, reducing the efficiency of the motor, and shortening the safety life, so as to reduce the cost of motor materials and heat dissipation. The effect of improving the effect and improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

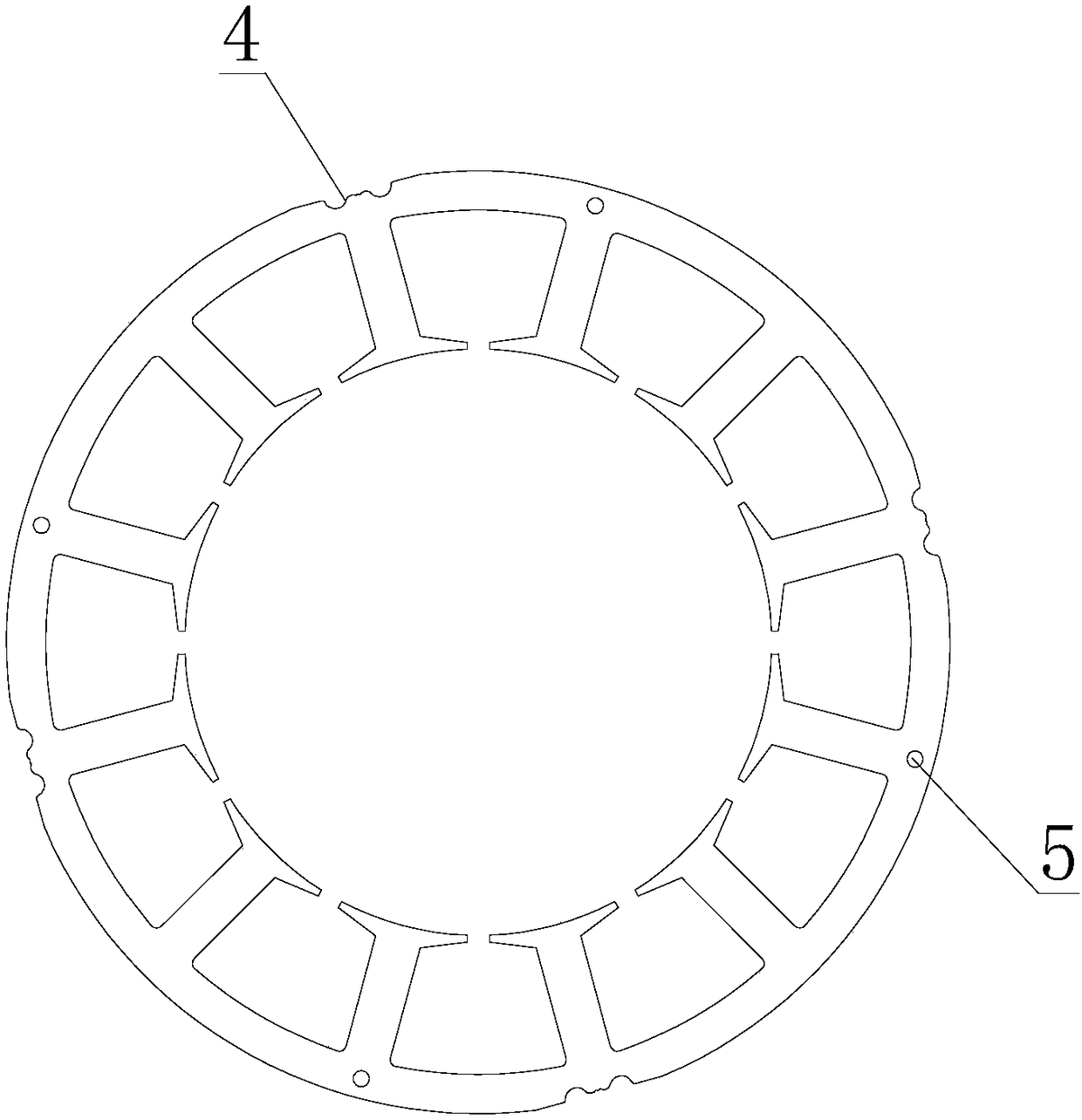

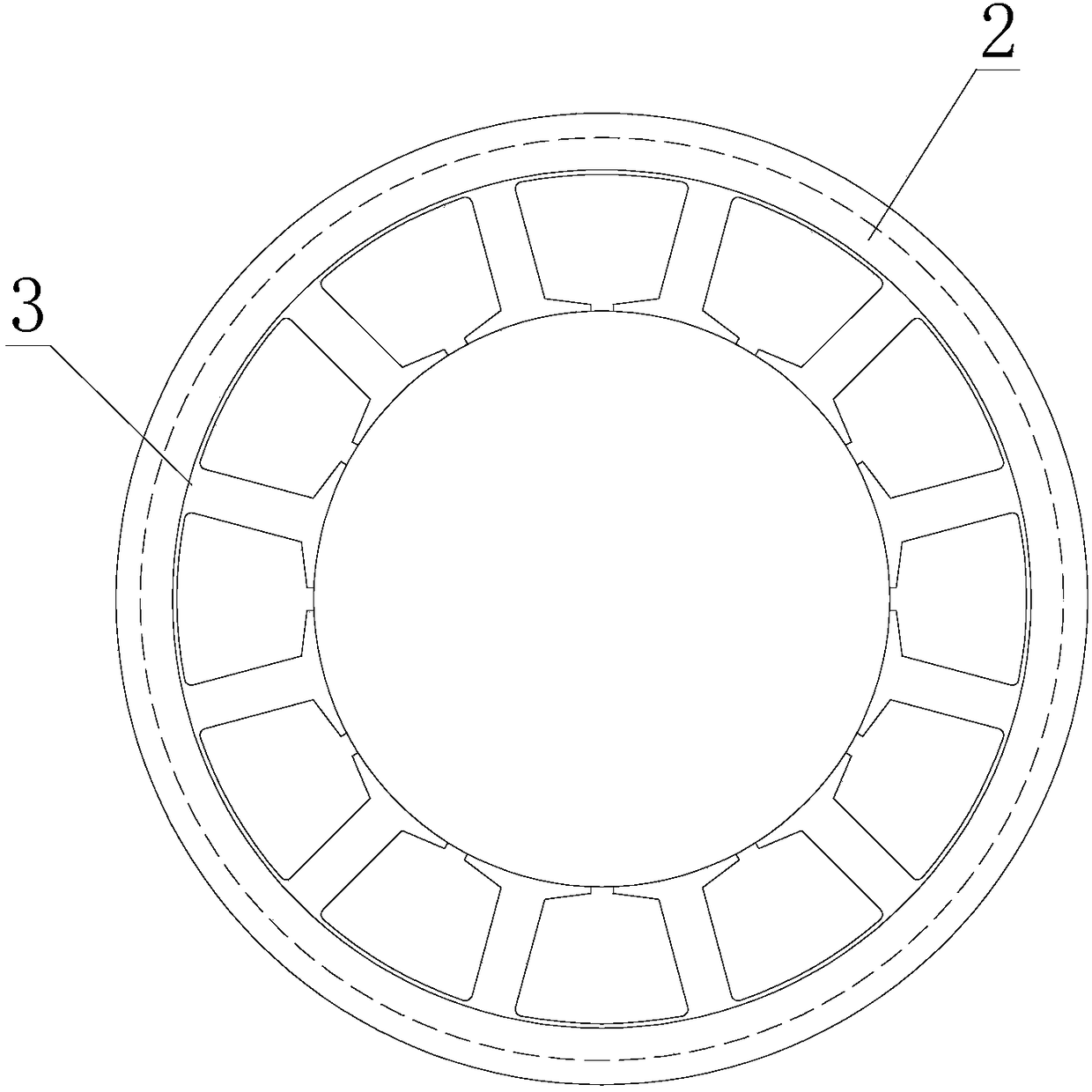

[0020] Attached below Figure 3-4 The technical scheme of the present invention will be further explained.

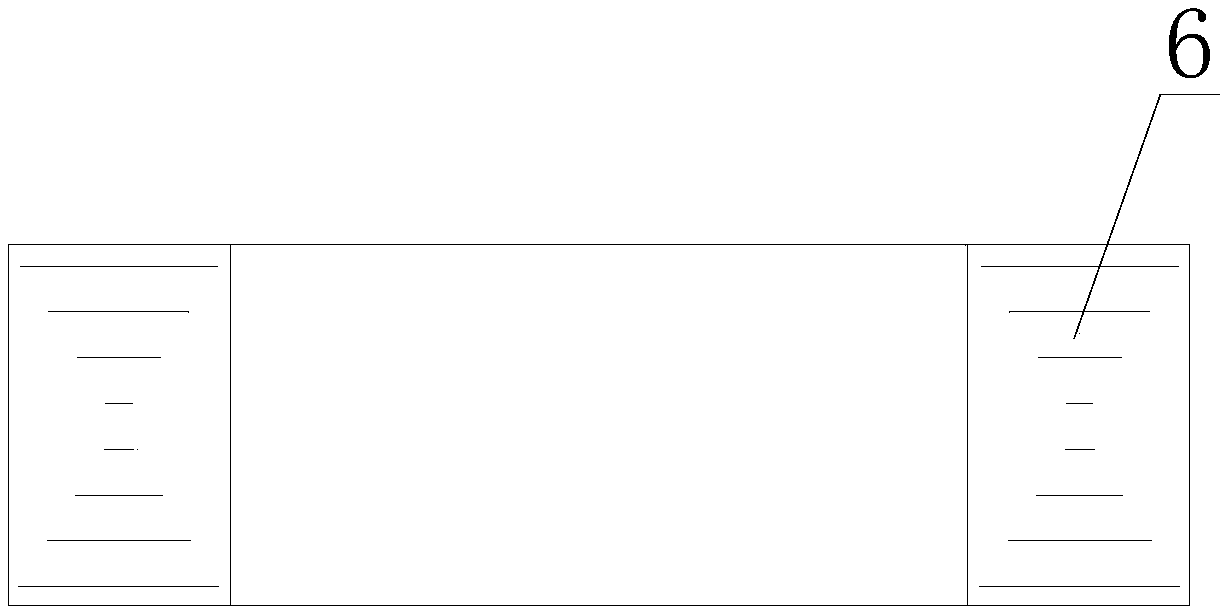

[0021] See attached Figure 3-4 As shown, the stator core of the above-mentioned new type of permanent magnet motor includes a molded body formed by laminating a plurality of stator punching pieces, and the integral non-magnetically conductive body is fastened to the outer circumferential surface of the molded body and the end faces of the yokes at both ends. Alloy cavity 1. The molded body includes a yoke part 3 and a tooth part. The integral non-magnetic alloy cavity 1 is an integral structure, and is integrally formed by fastening and rolling extrusion. The integral non-magnetic alloy cavity 1 includes one-to-one corresponding joining parts 2 on the end faces of the yokes at both ends of the molded body. The width of the coupling portion 2 is not greater than the width of the yoke 3. The coupling part 2 is coaxially distributed with the molded body, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com