Process for assembling stator iron core of 3MW permanent-magnet synchronous wind power generator

A technology of permanent magnet synchronization and assembly technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low lamination coefficient, low efficiency, and reduced yield rate, etc., and achieve the effect of increasing lamination coefficient, improving quality, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

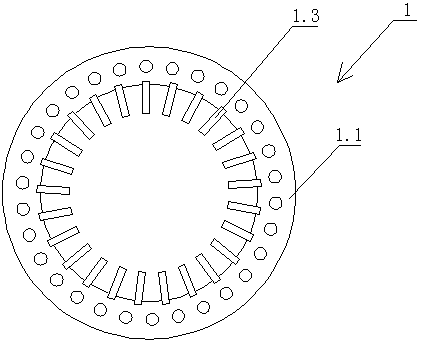

[0038] see Figure 1~6 , a kind of 3MW permanent magnet synchronous wind generator stator core assembly process that the present invention relates to, it is characterized in that: described process comprises the following steps:

[0039] Step A: Assembly of the stator tooth pressure plate;

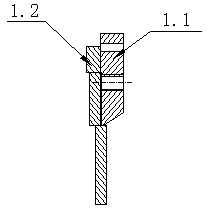

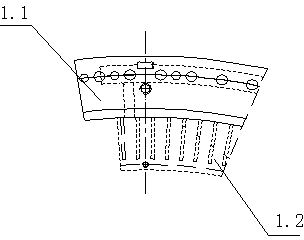

[0040] A1: Place the ring-shaped pressing plate 1.1 horizontally on the worktable, and press-fit the fan-shaped welding die 1.2 on the ring-shaped pressing plate 1.1. Both the ring-shaped pressing plate 1.1 and the fan-shaped welding die 1.2 have mark ports and pin holes. The ring-shaped pressing plate 1.1 Align with the fan-shaped welding mold 1.2 through the mark opening, and insert the positioning pins to fix after aligning the pin holes. The fan-shaped welding mold 1.2 is pre-evenly provided with a plurality of indexing grooves for placing the bead 1.3;

[0041] A2: Put the bead 1.3 into the groove pre-opened on the fan-shaped welding mold 1.2, the bottom surface of the bead 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com