Chain type stator core and motor

A stator core and chain technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of small lamination spacing and difficult rotation of the stator core, and achieve the effect of increasing the lamination coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

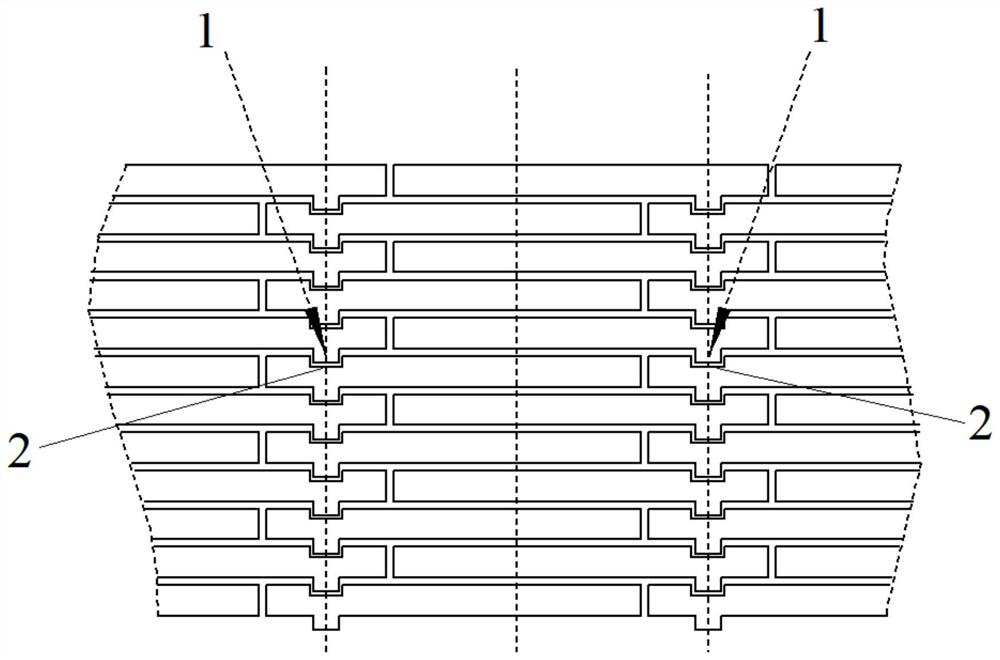

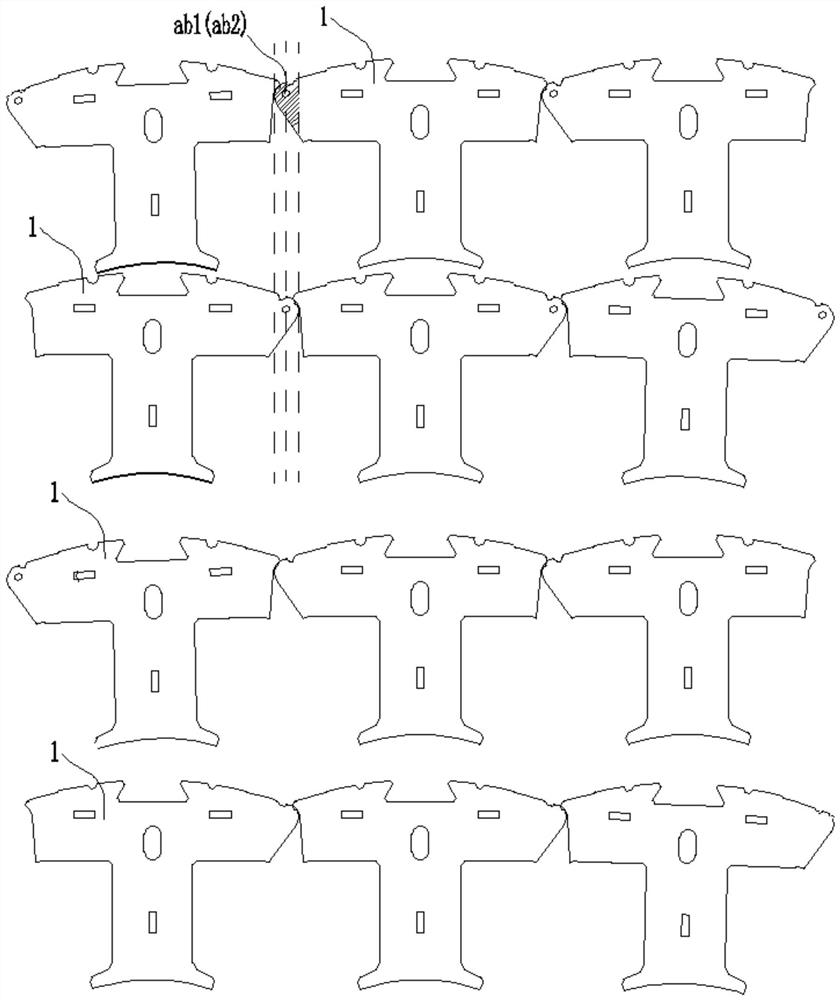

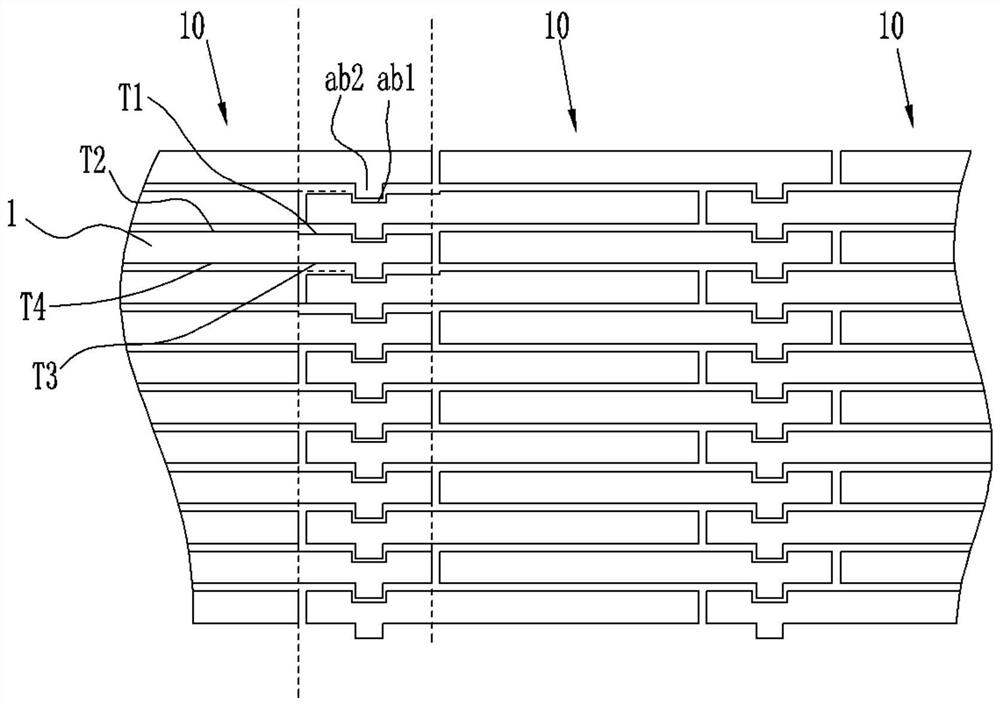

[0034] In this embodiment, a chain stator core is provided, such as figure 2 and image 3 As shown, it includes several stator core units 10, any one of the stator core units 10 is formed by lamination of several stator core laminations 1, and the stator cores of two adjacent stator core units 10 are stacked The pieces 1 are rotated and fastened together to form a stator core chain, and the two ends of the stator core chain are fixedly connected to form the chain stator core, and the rotation connections of the two mutually rotating and fastened stator core laminations 1 The spacing between regions is greater than the spacing between non-rotatingly connected overlapping regions.

[0035] As a preferred implementation manner of this embodiment, the thickness of the overlap area of rotation connection on any of the stator core laminations 1 is smaller than the thickness of the non-rotation connection overlap area of the stator core lamination 1 itself.

[0036] like figu...

Embodiment 2

[0047] In this embodiment, a chain stator core is provided, such as Figure 8 As shown, it includes several stator core units 10, any one of the stator core units 10 is formed by lamination of several stator core laminations 1, and the laminations of two adjacent stator core units 10 rotate with each other Buckled together to form a stator core chain, the two ends of the stator core chain are fixedly connected to form the chain-type stator core, and the stator core laminations 1 on any one of the stator core units 10 are divided into the first group and the second group, the stator core laminations of the first group are distributed on both sides in the thickness direction of the stator core laminations 1 of the second group, and the first two adjacent stator core units 10 The sets of stator core laminations 1 are rotated and fastened together, and only the end edges of the second set of stator core laminations 1 on two adjacent stator core units 10 cooperate with each other. ...

Embodiment 3

[0059] In this embodiment, a motor is provided, including the chain stator core described in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com