Multihole drill transmission mechanism

A transmission mechanism and multi-hole drilling technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of affecting processing accuracy, low production efficiency, increasing labor intensity of workers, etc., and achieve improvement Improve processing efficiency and reduce the effect of repeated clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

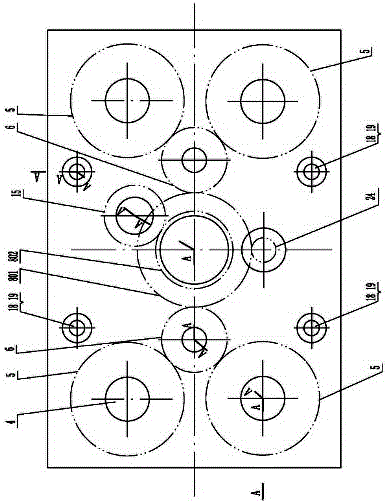

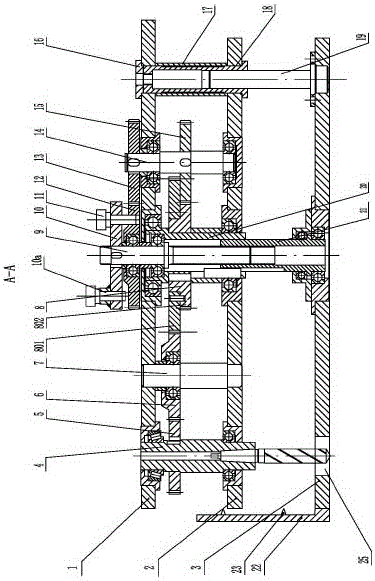

[0016] As shown in Figure 1 and Figure 2, the multi-hole drill transmission mechanism of the present invention includes an upper plate 1, a middle plate 2 and a lower plate 3, and the middle plate 2 and the upper plate 1 respectively support a plurality of drill rod shafts 4 through bearing rotation, and the drill Drill bits are respectively fixedly installed on the rod shaft 4, drill pipe holes 25 for the passage of the drill bits are correspondingly provided on the lower plate 3, and some holes 25 for making the upper plate 1 and the middle plate 2 relatively fixed are also arranged on the middle plate 2 and the upper plate 1. The support sleeve mechanism, the lower plate 3 is respectively provided with a number of guide columns 19 that slide up and down with the inner hole of the support sleeve mechanism, the center of the middle plate 2 and the upper plate 1 is supported by a hollow shaft sleeve 20, and the lower plate 3 is supported by rotation. There is a threaded guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com