Conveying and packaging mechanism

A conveying device and packaging technology, applied in directions such as packaging, can solve the problems such as the inability of the packaged objects 12 to be neatly arranged upright, the packaged objects 12 toppling, and the effect of affecting the packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

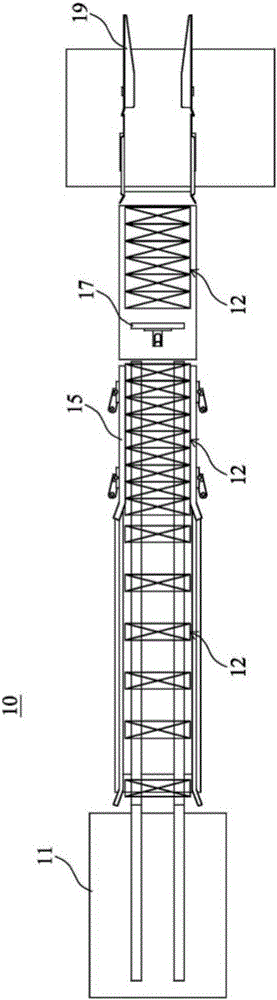

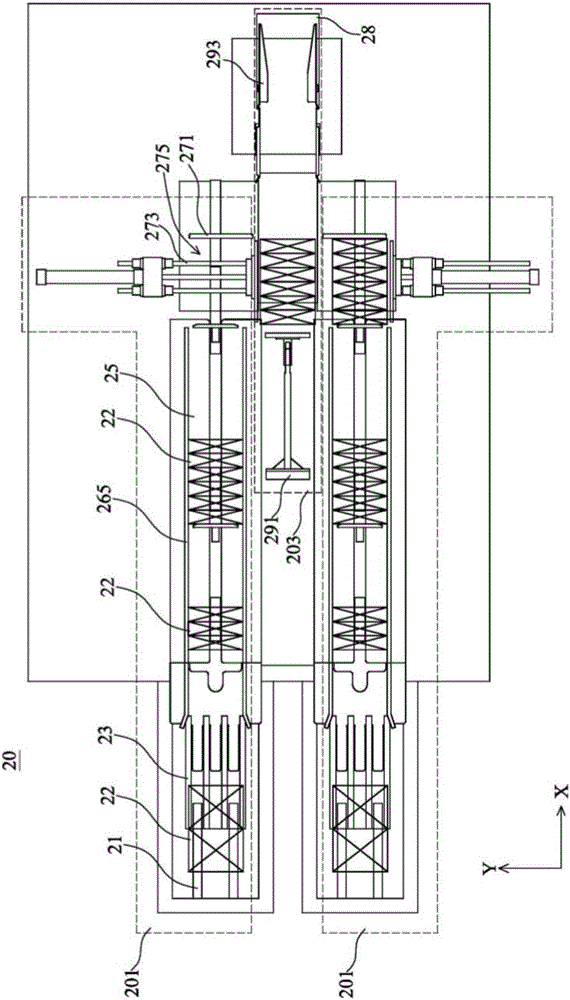

[0028] see image 3 and Figure 4 , are respectively a top view and a side view of an embodiment of the conveying and packaging mechanism of the present invention. As shown in the figure, the conveying and packaging mechanism 20 mainly includes at least one conveying module 201 and at least one packaging module 203 , wherein the packaging module 203 is disposed downstream of the conveying module 201 . The conveying module 201 includes a conveying device 21 , a turning wheel 23 , a first circulation pushing device 24 and a second circulation pushing device 25 , and the packaging module 203 includes a feeding device 291 and a bag opening device 293 .

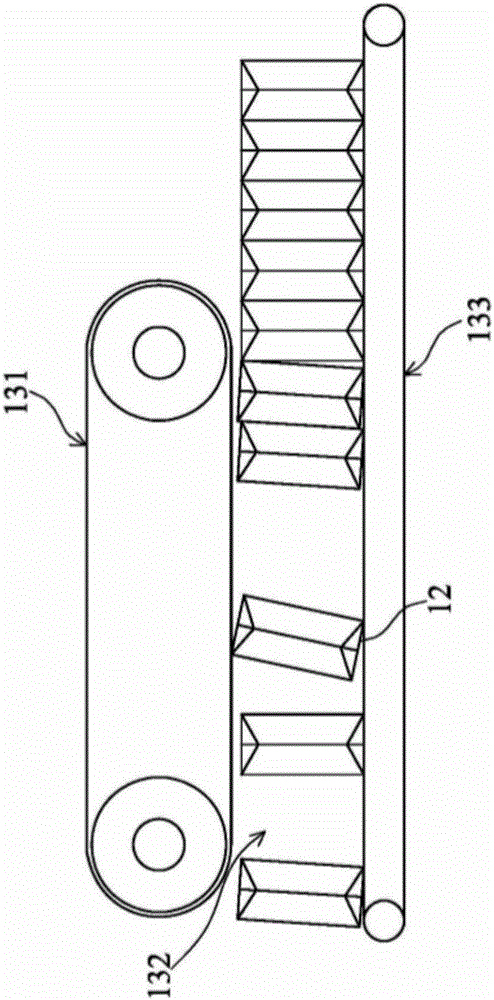

[0029] The conveying device 21 can be used to convey at least one packaged object 22 , for example, the conveying device 21 can be used to convey a packaged object 22 lying on i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com