Stepped type drilling template for sectional type spindle connecting pin hole of compressor and auxiliary guide sleeve

A stepped and formwork technology, applied in the field of compressors, can solve the problems of high purchase and application costs, and achieve the effect of improving the accuracy of drilling operations and simplifying finishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

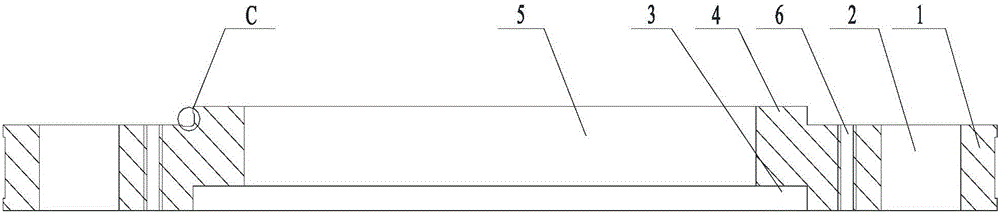

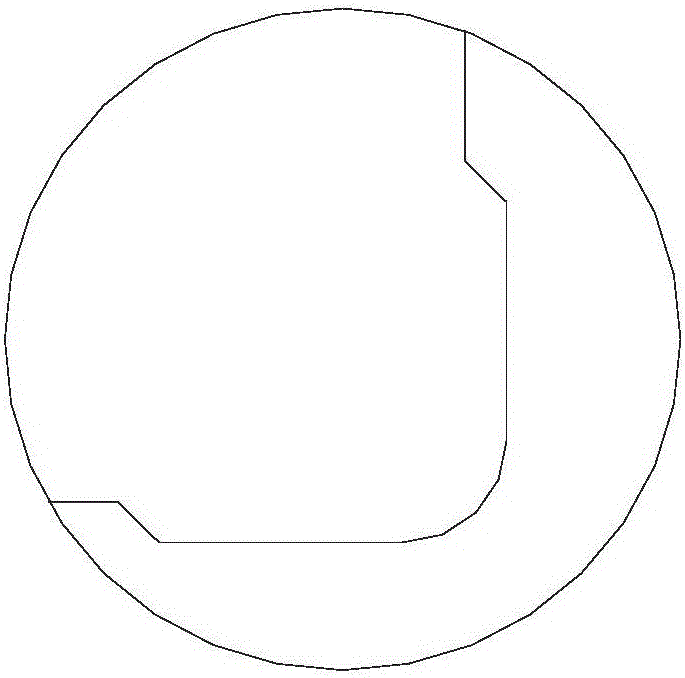

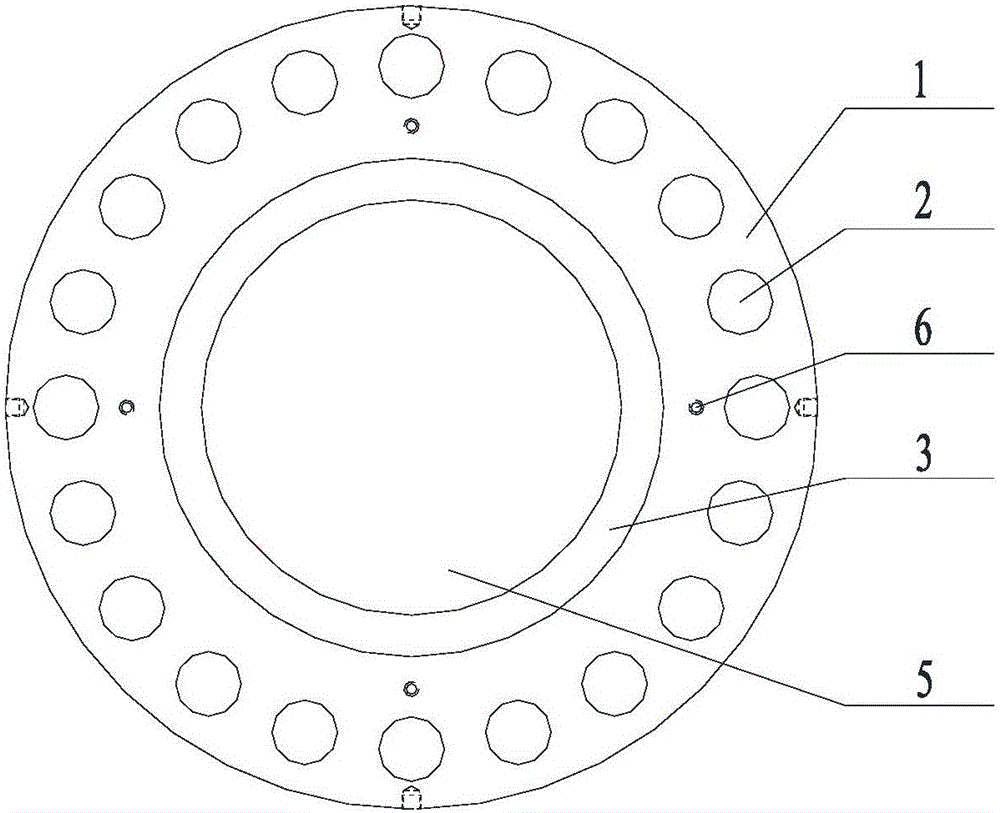

[0051] See attached figure 1 And attached image 3 The stepped drilling template provided by the embodiment of the present invention includes a first body 1, the first body 1 is in the shape of a stepped cylinder, the center of the first body 1 is provided with a first through hole 5, and around the first through hole 5, there are There are several second through holes 2, and the centers of circles of the several second through holes 2 are on the first circumference. Around the first through hole 5, there are several third through holes 6, and several third through holes 6 The center of the circle is on the second circle together, the first through hole 5, the first circle and the second circle are concentric circles, the diameter of the first through hole 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com