Construction method of full-casing follow-up long spiral drilling press-grouting secant pile

A technology of long helical drilling and construction method, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc. It can solve the problems of increasing the difficulty of cutting steel casings, affecting the water-stop effect of walls, and inconsistent setting time, etc., to achieve Reduce the chance of water seepage, improve drilling efficiency, and enhance the effect of water sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

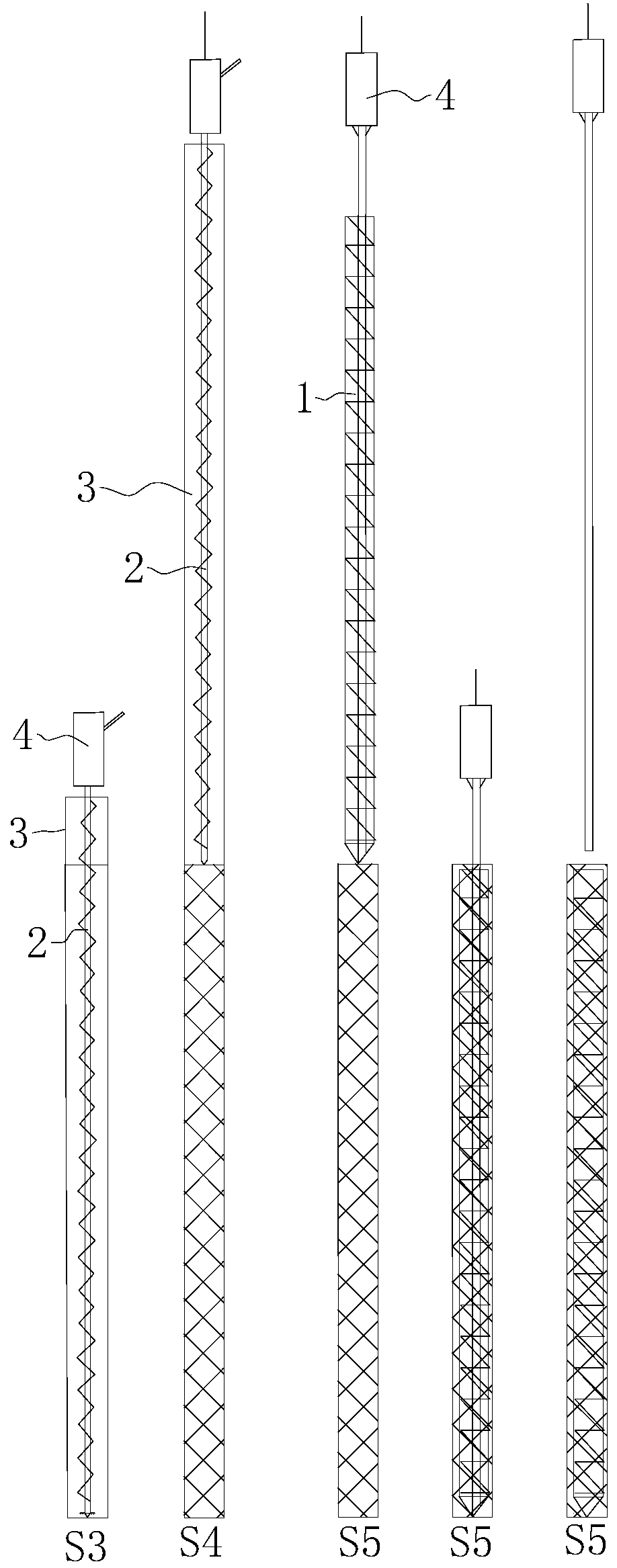

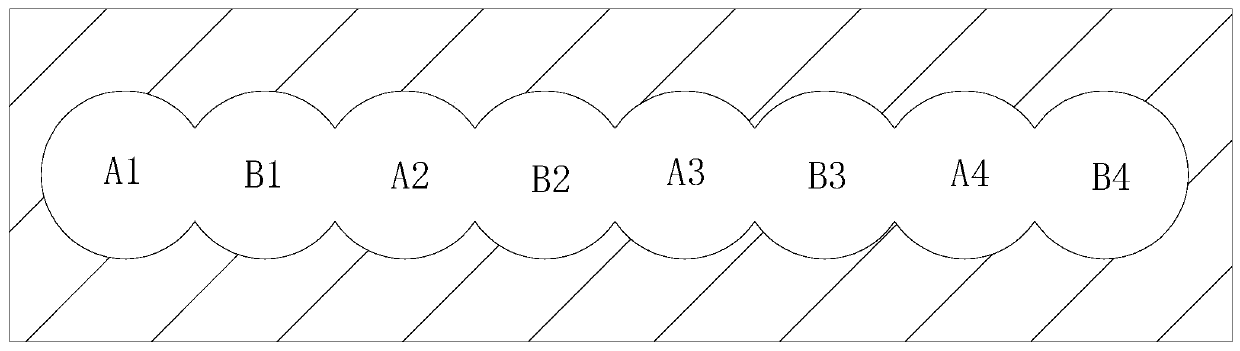

[0051] Embodiment 1: refer to figure 1 and 2 , which is a construction method for a full-casing follow-up long auger bored pressure grouting occlusal pile disclosed by the present invention, the steps are as follows:

[0052] S1, positioning and setting out, according to the pile location plan and site reference point, measure and place the pile location on the construction site and drive in obvious marks.

[0053] S2, guide wall construction:

[0054] S2.1, leveling the site: clearing the debris on the surface, and filling the grooves for the migration of the rolled underground pipeline; After the completion, the soil layer in the hole should be compacted, which is conducive to the correct positioning of the steel casing 3;

[0055] S2.2, measuring and placing pile positions: use the total station to carry out on-site stakeout according to the control points of the ground wires, and mark them as the control center line of the guide wall construction.

[0056] S2.3, Excava...

Embodiment 2

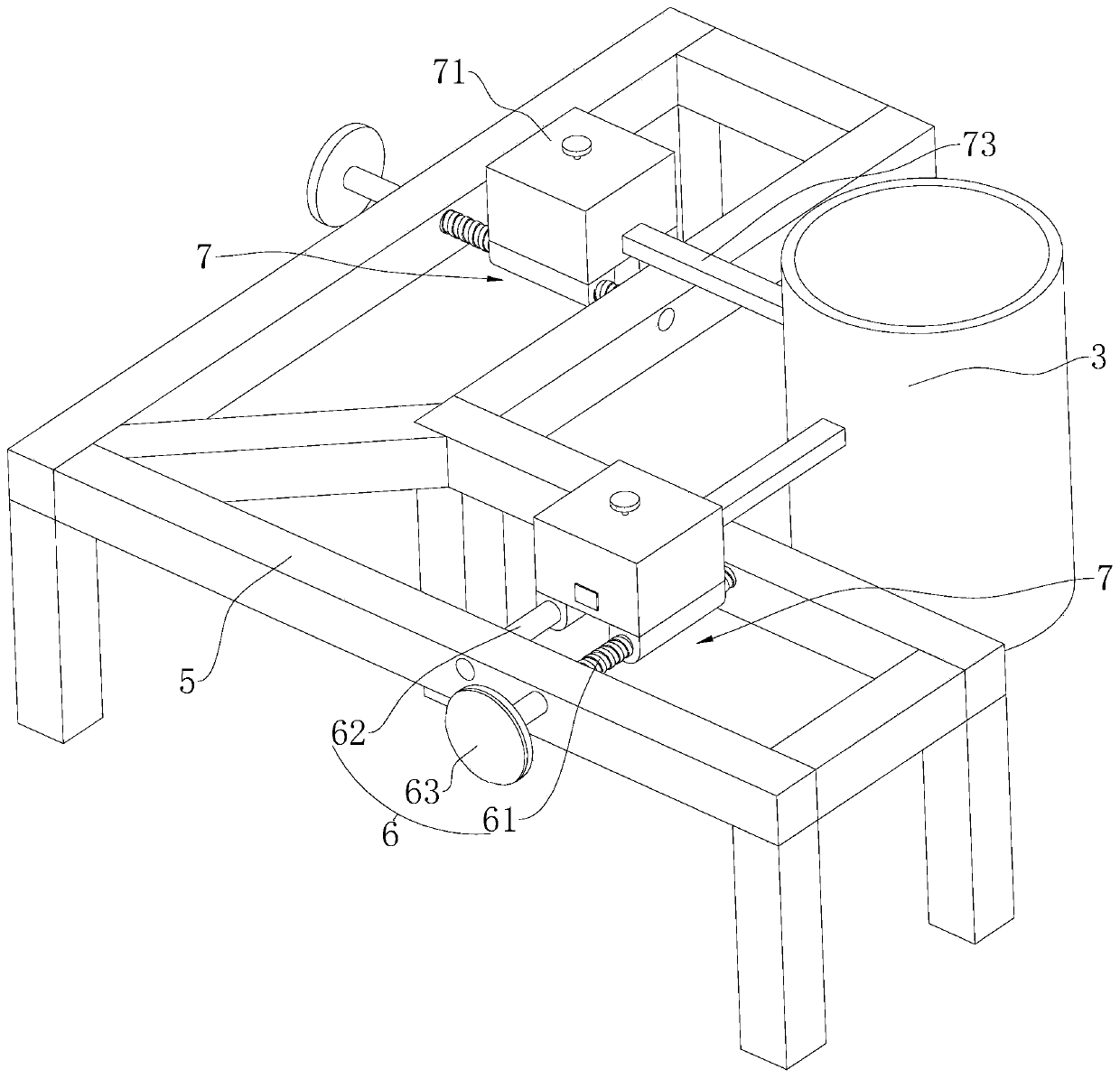

[0089] Embodiment 2: refer to image 3 , an auxiliary mechanism for adjusting the position of the steel casing 3 during the construction of the occlusal pile; it includes a frame 5, the vertical projection plane of the frame 5 is L-shaped, and pushers are respectively arranged on both sides of the upper end of the frame 5 7. The two pushers 7 are arranged vertically to each other; refer to Figure 4 and 5 : The pusher 7 includes being installed on the frame 5 (refer to image 3 ) on the mounting seat 71, the mounting seat 71 is provided with a chute 72 along the radial direction of the steel casing 3, and a push rod 73 is inserted in the chute 72, and a displacement block is fixed on one side of the push rod 73 inside the chute 72 74, the displacement block 74 is the fixed isosceles trapezoid setting of the lower bottom and the push rod 73, so that the two sides of the displacement block 74 along the push rod 73 transmission direction are inclined-plane one 78 and inclined-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com