A device for adjusting the shape of a glass plate

A glass plate and cutting device technology, applied in glass forming, glass forming, glass production, etc., can solve problems such as shape recovery of glass plate, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

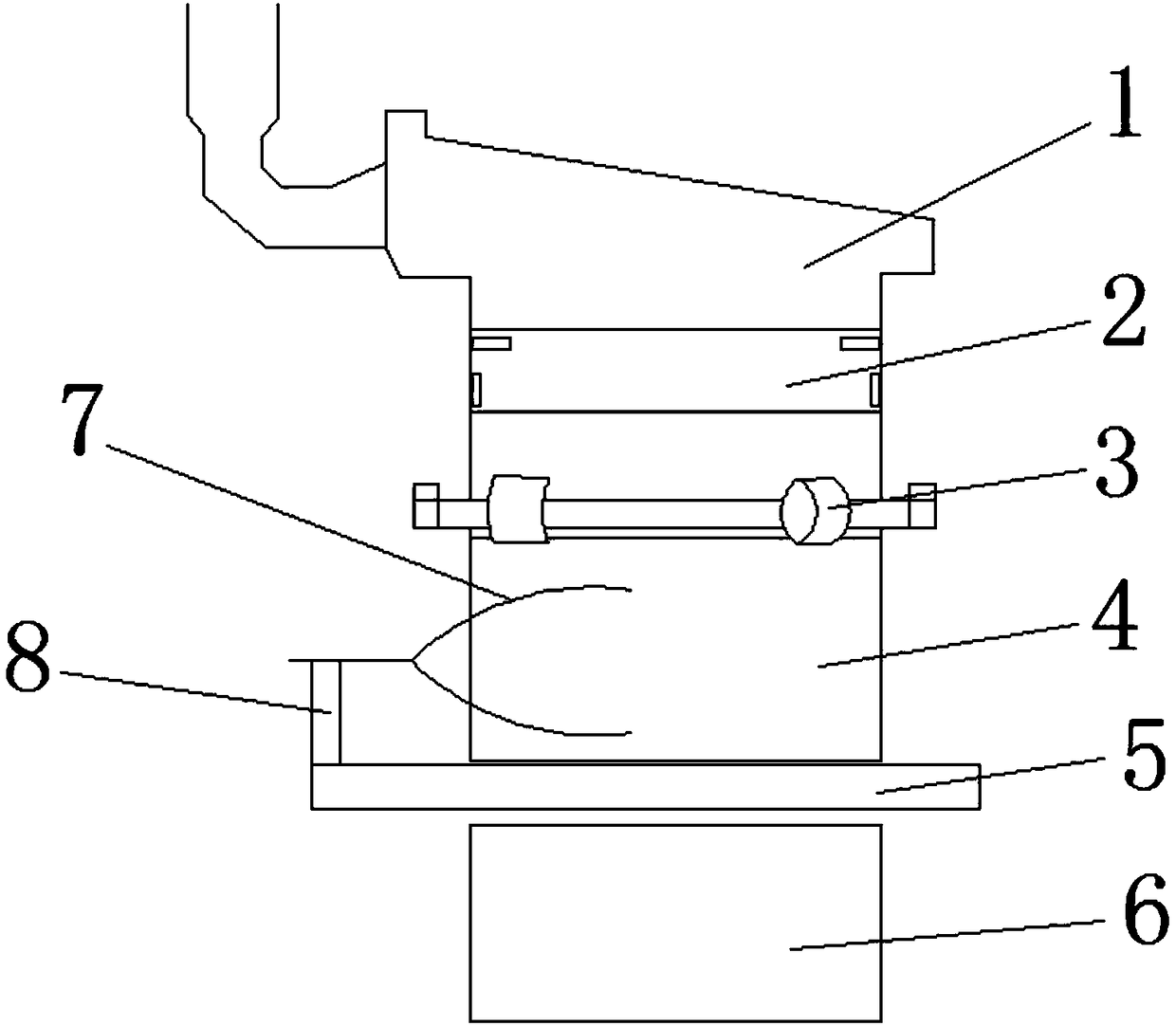

[0021] The invention provides a device for adjusting the shape of a glass plate, such as figure 1 As shown, the overflow down-draw forming equipment 1 is included, and the glass sheet outlet of the overflow down-draw forming equipment 1 is provided with a deflector 2, and a traction roller 3 is arranged under the deflector 2, and the forming of the glass plate is under the traction roller 3. In the area, a fork device 7 is arranged on the surface of the glass plate, and the fork device 7 wants to exert an opposite force on the glass plate relative to the existing shape; the fork device 7 is a U-shaped structure, and the U-shaped structure is in contact with the surface of the glass plate The part has a certain radian; the shifting fork device 7 is connected with the rotating shaft 8, and the shifting fork device 7 can perform an arc-shaped reciprocating motion around t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com