Oil-water separation interface device and application thereof in separation of silicone oil and water

A silicone oil, oil-water separation technology, applied in the direction of grease/oily substance/float removal device, liquid separation, separation method, etc., to achieve the effect of reducing residual amount, reducing side reactions and prolonging operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

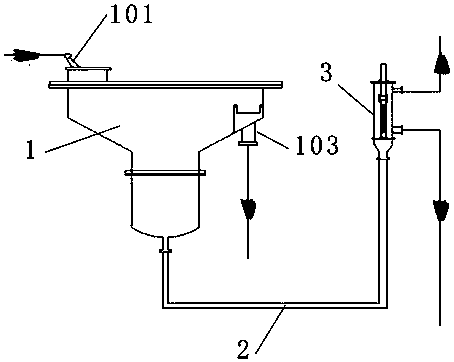

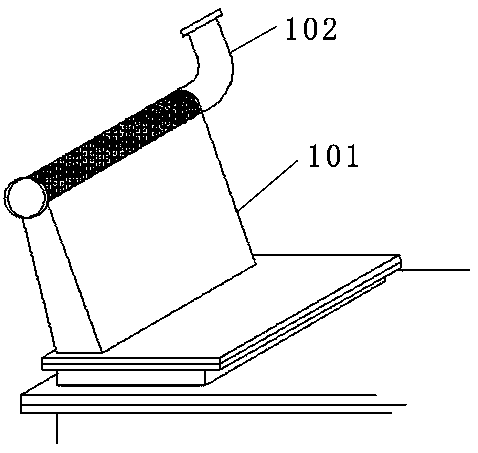

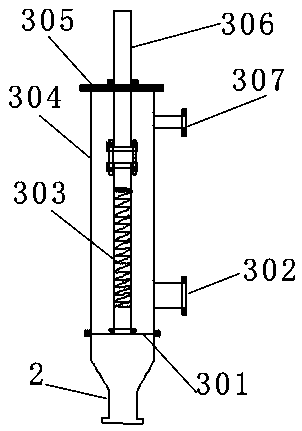

[0032] An oil-water separation interface device, comprising: a decanter 1 and an interface regulator 3; wherein, the bottom of the decanter 1 and the bottom of the interface regulator 3 communicate with each other through a conduit 2; the decanter 1 The upper part is provided with an introduction part that is conducive to fluid buffer input; the introduction part includes a slope plate 101 and a liquid inlet pipe 102;

[0033] One side of the described decanter 1 is fixedly equipped with a slope plate 101; the interior of the slope plate 101 is hollow, and the inner chamber on one side of the top of the slope plate 101 communicates with the liquid inlet pipe 102; the top of the decanter 1 is square , the lower part is a circular cylinder.

[0034] An application of an oil-water separation interface device in separating silicone oil and water, characterized in that: the separation interface device for silicone oil and water phase mixture includes: a decanter 1 and an interface ...

Embodiment 2

[0044] All the other are the same as embodiment 1

[0045] An oil-water separation interface device and its application in separating silicone oil and water, wherein the mixture of silicone oil and water phase is composed of the following components in parts by weight: 90 parts of silicone oil, 25 parts of water phase, and 8 parts of colloid .

[0046] The water phase in the silicone oil and water phase mixture is formic acid.

[0047] The liquid inlet pipe 102 model in the described organosilicon oil and aqueous phase mixture separation device is DN90, and the pipe wall thickness is 15mm.

[0048] The material used for the decanter 1, the ramp plate 101, and the liquid inlet pipe 102 in the silicone oil and water phase mixture separation device is alloy steel.

[0049] The inclination angle of the slope plate 101 in the described silicone oil and water phase mixture separation device is: 45 degrees; wherein the area of the slope is 80 m 2 .

[0050] In the control of th...

Embodiment 3

[0052] All the other are the same as embodiment 1

[0053] An application of an oil-water separation interface device for separating silicone oil and water, wherein the mixture of silicone oil and water phase is composed of the following components in parts by weight: 75 parts of silicone oil, 30 parts of water phase, and 10 parts of colloid.

[0054] The water phase in the silicone oil and water phase mixture is formic acid.

[0055] The liquid inlet pipe 102 model in the described silicone oil and aqueous phase mixture separation device is DN70, and the pipe wall thickness is 12mm.

[0056] The material used for the decanter 1, the ramp plate 101, and the liquid inlet pipe 102 in the silicone oil and water phase mixture separation device is carbon steel.

[0057] The inclination angle of the slope plate 101 in the described silicone oil and water phase mixture separation device is: 30 degrees; wherein the area of the slope is 40 m 2 .

[0058] In the control of the oil-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com