Intelligent power catwalk

A catwalk and power technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of reduced production efficiency, low transportation efficiency, low degree of automation, etc., to improve the degree of intelligence, reduce labor intensity, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

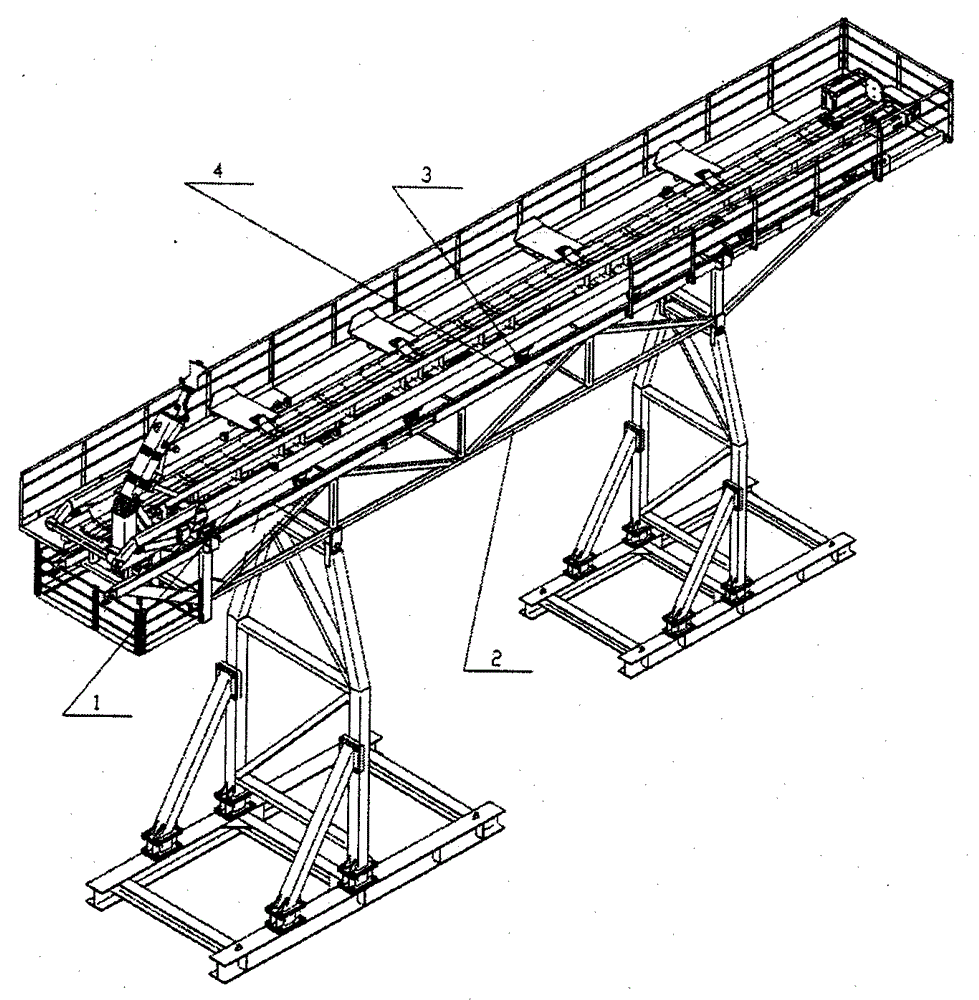

[0019] Example 1: Combining Figure 1-Figure 7 , a kind of intelligent power catwalk of the present invention, it is made up of bracket (1), track (4), wheel set (3), mechanical arm assembly (225) and catwalk main body (2), and catwalk main body (2 ) is placed on the track (4) of the support (1) through the wheel set (3), and the mechanical arm assembly (225) is installed on the catwalk main body (2).

[0020] The present invention also has the following technical characteristics:

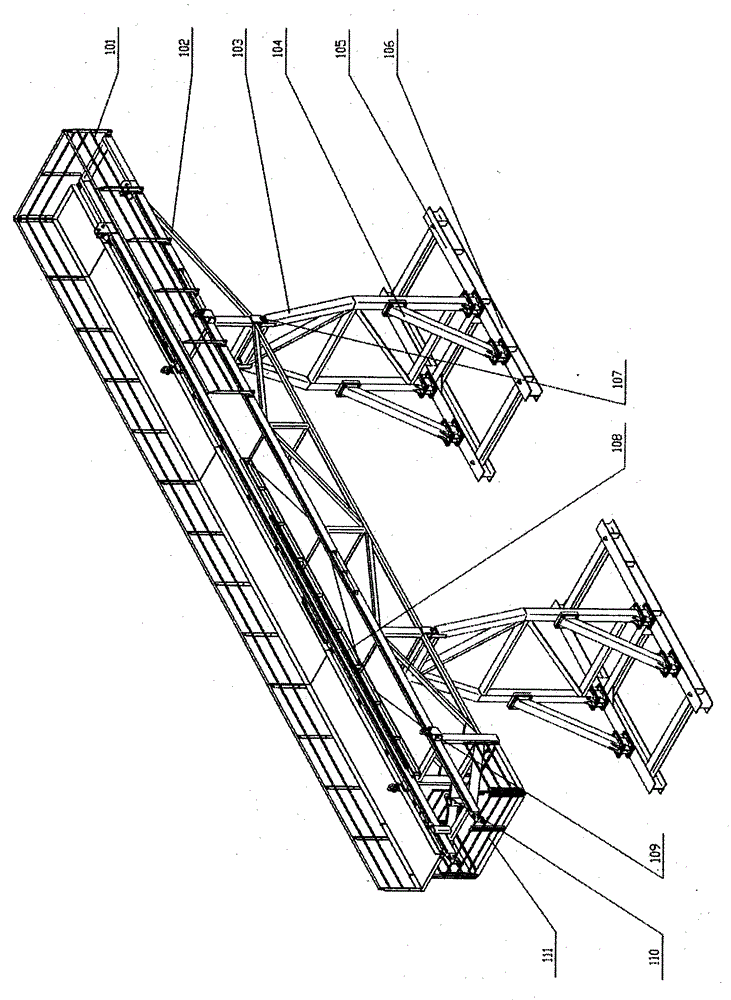

[0021] The bracket (1) includes a track (4), a guardrail (101), an upper frame (102), a 10-type frame (103), a supporting leg (104), a base (105), a supporting block (106), a pin (107), rack (108), suspension ring (109), buffer ball (110) and hydraulic equipment column (111), support block (106) and base (105) bolts are connected together, and 10 type frame (103) passes Bolts are connected to the support block (106), and the support legs (104) are respectively connected to the support block (106)...

Embodiment 2

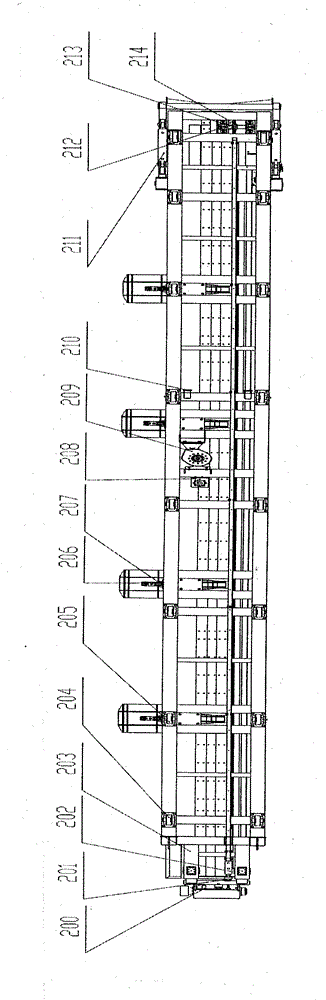

[0024] Example 2: Combining Figure 8 , implementation plan 1: catwalk main body position and angle adjustment

[0025] The two bases (105) are installed on the bottom surface of the workbench with one end fixed and a section free, and the supporting legs (106) are elongated correspondingly through the drive of the hydraulic cylinder, so that the catwalk main body (2) can be realized through the cooperation of the two supporting legs (106). Adjust the height and angle to achieve the required position of the target working platform. Implement multi-platform applications.

[0026] Drill pipe loading

[0027] The main body of the catwalk (2) stays at the waiting station, and the crane lifts the drill pipe from the pile of rods and puts it on the loading plate (243), and one end of the loading plate (243) passes through the pin shaft (207) of the loading plate in a hinged form. ) is connected with the loading plate hydraulic cylinder (206), the other side of the loading plate h...

Embodiment 3

[0036] Example 3: Binding Image 6 , Embodiment 2: The position and angle adjustment of the main body of the catwalk, the loading of the drill pipe, the transportation of the drill pipe, the walking of the main body of the catwalk, and the unloading of the drill pipe are basically the same as the first embodiment, the difference lies in the adjustment of the drill pipe, Embodiment two has increased manipulator assembly (225) such as Figure 7 shown. The lifting arm (226) is hinged on the body welding structure (203) through the lifting arm connecting pin (229), and the lifting arm hydraulic cylinder (227) is hinged on the lifting arm (226) and welded with the body through the lifting arm hydraulic cylinder pin (228). On the structure (203), the lifting arm (226) lifts the drill pipe that has reached the destination point to a specified height under the promotion of the lifting arm hydraulic cylinder (228), and the mechanical arm assembly (225) assists in adjusting the drill p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com