Method for making inner lining paper and made inner lining paper

A technology of lining paper and lining paper, which is applied in the field of tobacco packaging, can solve the problems of single form, unsatisfactory aesthetics, and no visible function, etc., and achieves convenient operation, favorable promotion and application, improved aesthetics and flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

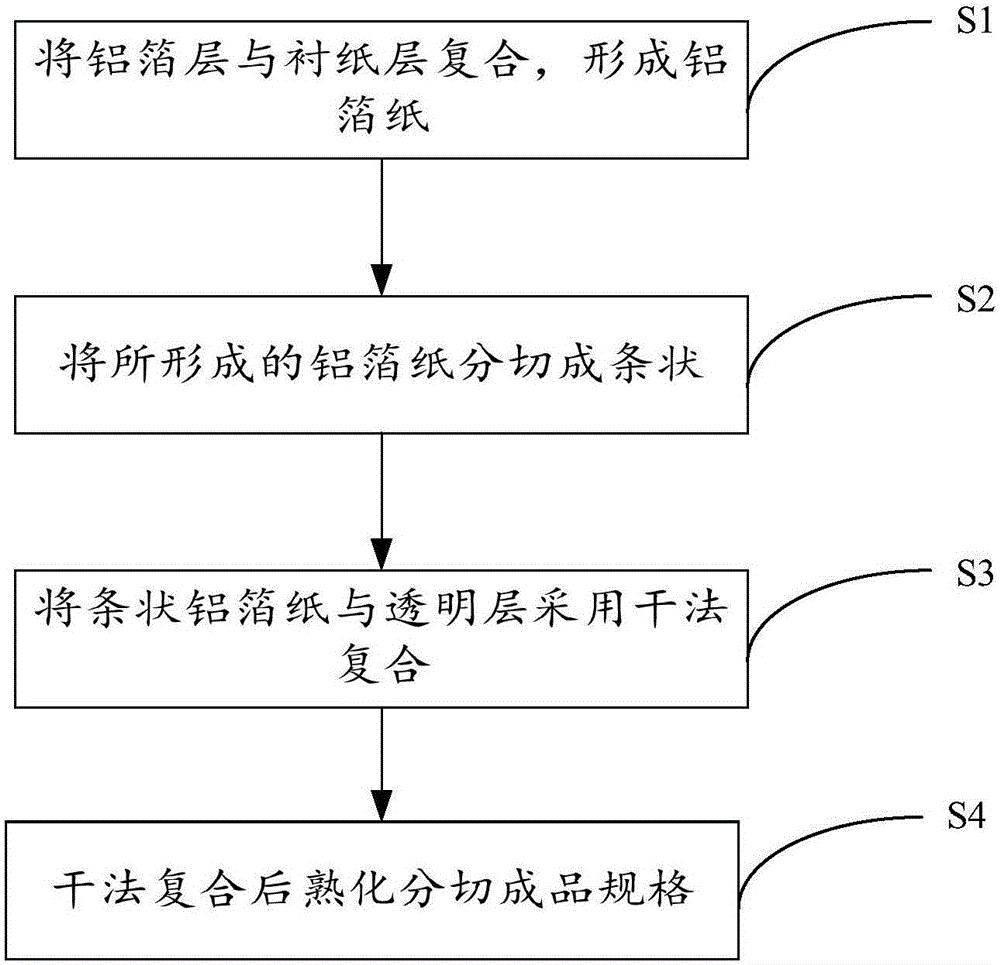

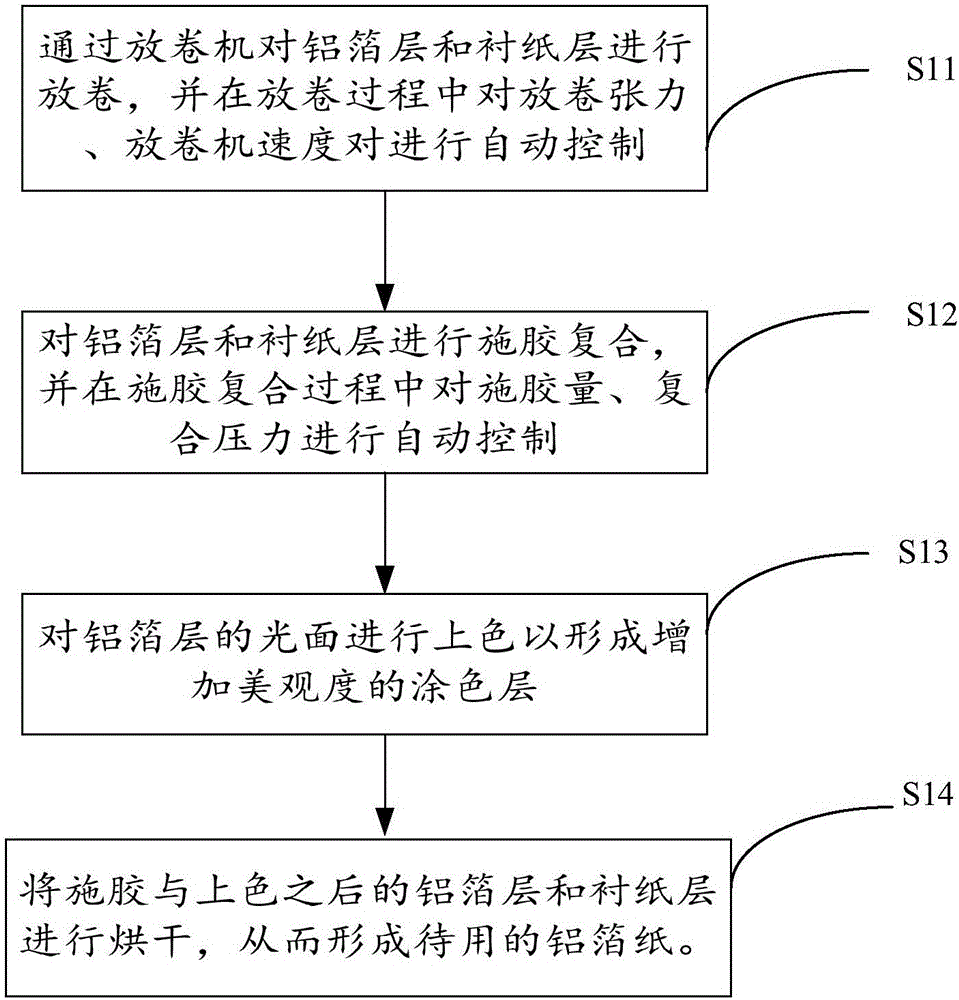

[0042] combine Figure 1 to Figure 3 Shown, the present embodiment one provides a kind of method for making lining paper, and it comprises the steps:

[0043] S1, compounding the aluminum foil layer and the backing paper layer to form aluminum foil paper;

[0044] S2, cutting the formed aluminum foil paper into strips;

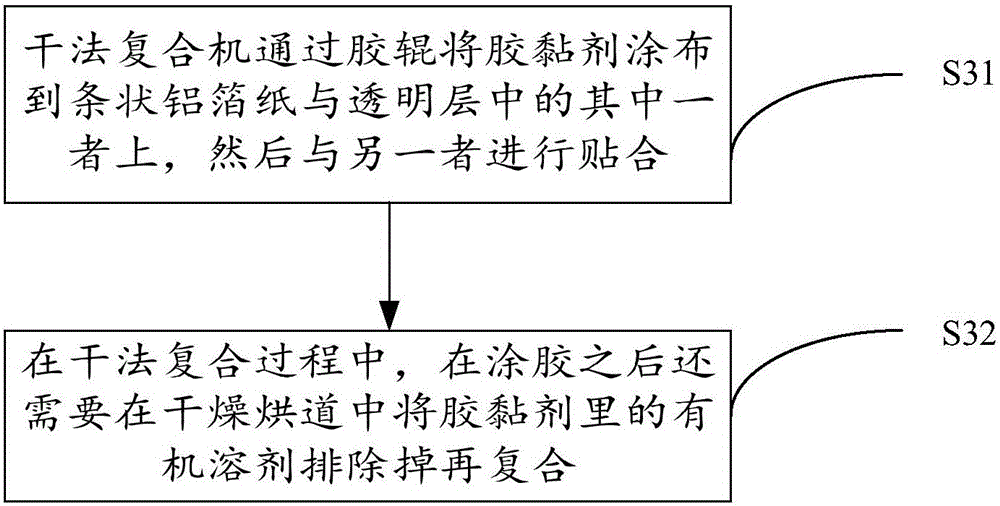

[0045] S3, compounding the strip aluminum foil paper and the transparent layer by a dry method;

[0046] S4, after dry compounding, aging and cutting into finished product specifications.

[0047] Through the above-mentioned method, a new type of inner lining paper which is composed of aluminum foil paper and transparent layer can be produced. The aluminum foil paper is distributed on both sides of the transparent layer in strips at intervals, forming a transparent area between adjacent aluminum foil papers. The method is not only convenient to operate and saves manpower in the technological process, but also can greatly improve the aesthetics and flexibili...

Embodiment 2

[0072] combine Figure 1 to Figure 4 As shown, the second embodiment discloses a lining paper, which is mainly made by the method for making the lining paper in the above-mentioned embodiment 1.

[0073] Specifically, the production process of the lining paper includes:

[0074] S1, compounding the aluminum foil layer 1 and the backing paper layer to form aluminum foil paper;

[0075] S2, cutting the formed aluminum foil paper into strips;

[0076] S3, compounding the strip-shaped aluminum foil paper and the transparent layer 2 by a dry method;

[0077] S4, after dry compounding, aging and cutting into finished product specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com