A fully automatic double top stop machine for metal pellets

A metal particle, fully automatic technology, applied in the direction of sliding fastener components, clothing, applications, etc., can solve the problems of low production efficiency, high production cost, unfavorable large-scale production, etc., to achieve the effect of convenient installation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

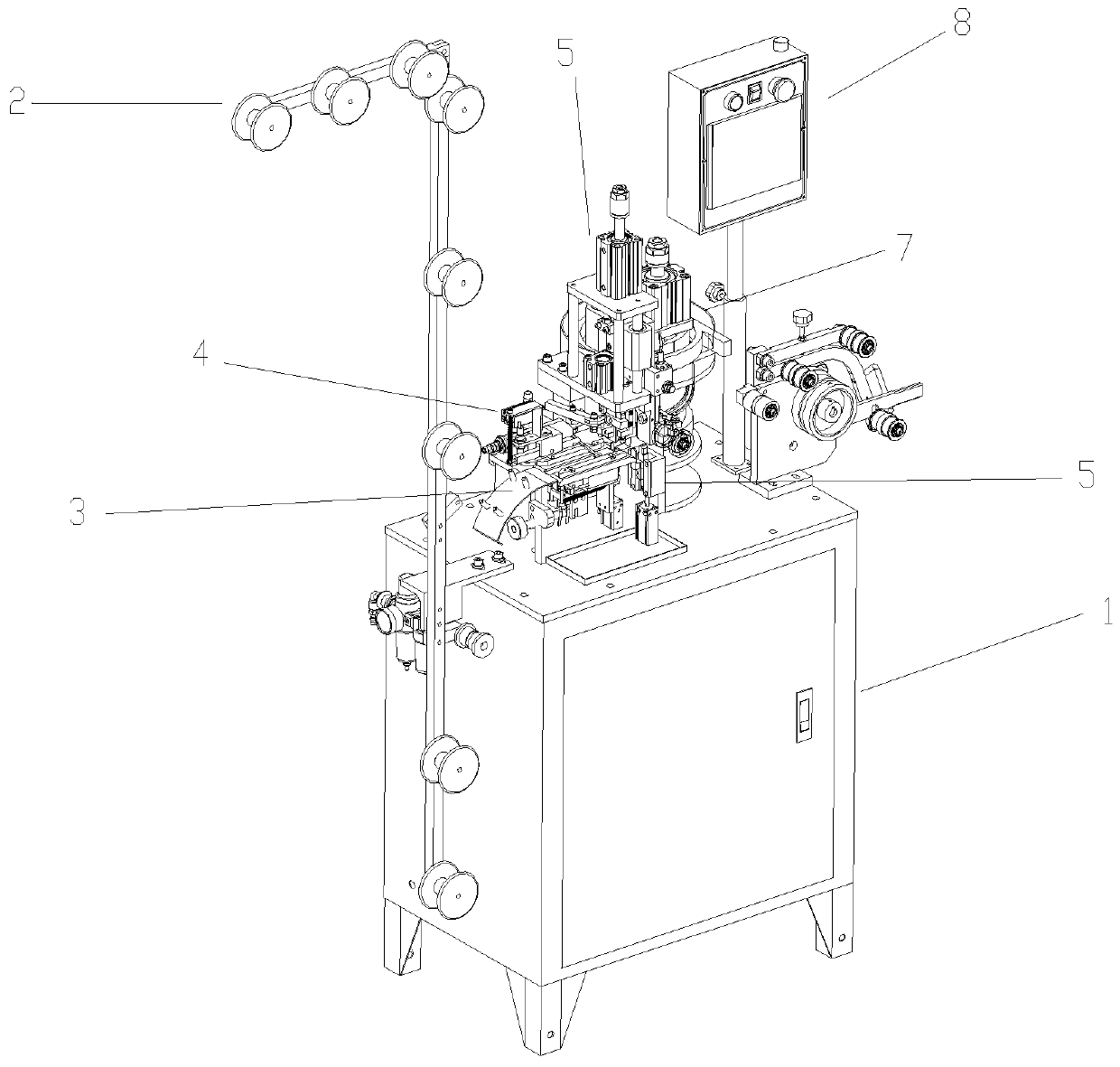

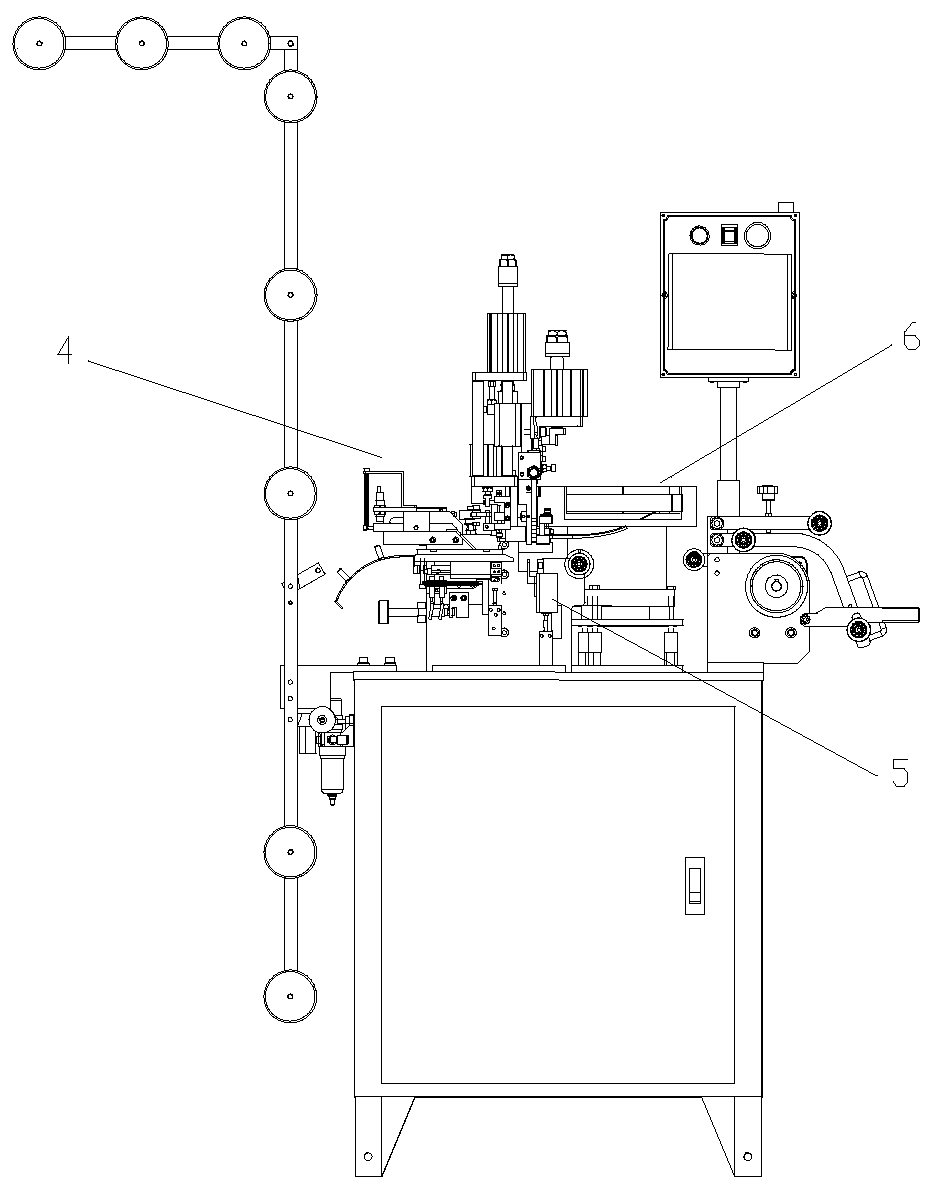

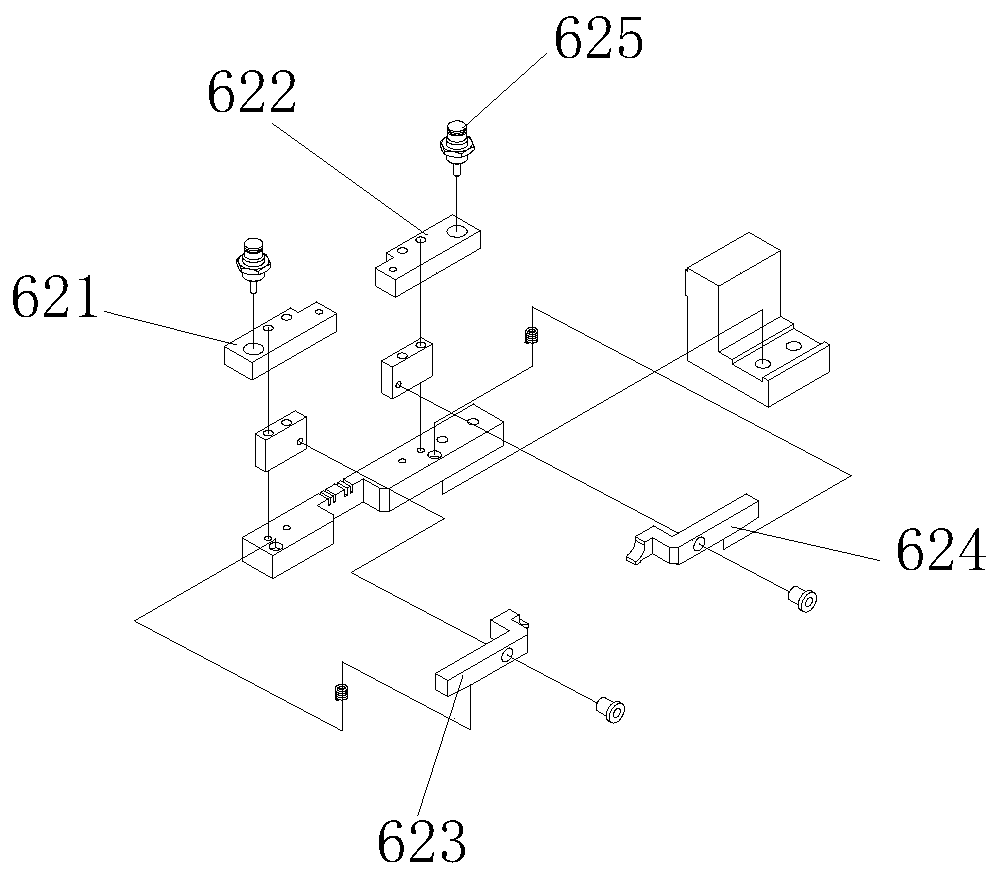

[0023] like Figure 1-8 As shown, a fully automatic metal particle material double top stop machine includes a frame 1, on which a belt passing device 2, a belt feeding device 3, a needle positioning device 4, a belt separating device 5, and an upper stop device are arranged. 6. The vibrating feeding device 7 and the controller 8, the belt passing device 2 is arranged at the front end of the frame 1, the belt feeding device 3 is connected with the belt passing device 2, and is used to send the zipper tape into the upper stop device 6; hook needle positioning Device 4 is arranged below the tape feeding device 3, and is used to locate the top stop position of the zipper tape; the top stop device 6 is arranged on the downstream of the tape feeding device 3, and the tape distribution device 5 is arranged below the top stop device 6, and the tape distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com