Glue spraying device and determination method of border track

A technology of spraying glue and frame, which is applied to the device and coating of the surface coating liquid, which can solve the problems of reduced execution efficiency of the whole machine, unstable glue spraying, and affecting the shooting accuracy of the CCD vision system, so as to avoid debugging Steps, simplify the operation process, improve the effect of shooting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

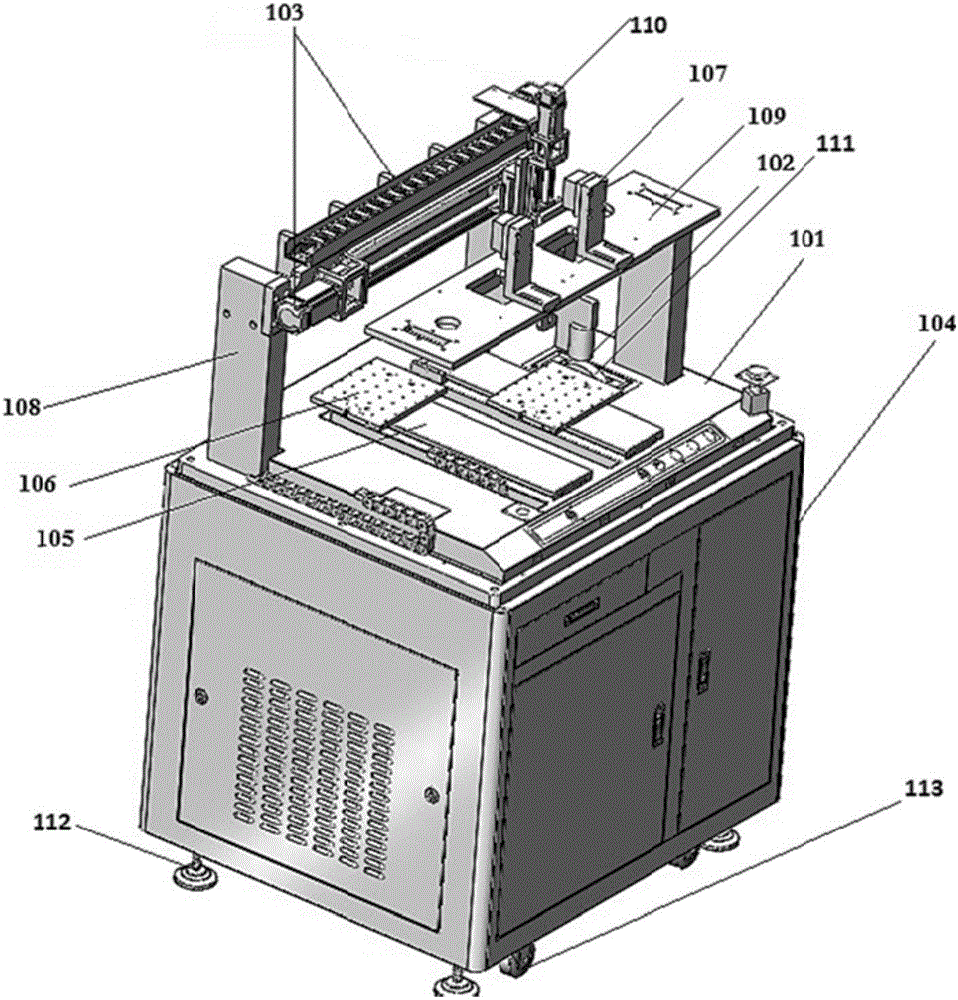

[0024] figure 1 It is a perspective view of a glue spraying device provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the glue spraying device includes: a workbench 101 , a controller (not shown), a glue spraying mechanism 102 , a motion actuator, a camera module (not shown) and a feeding module 105 .

[0025] The workbench 101 has a camera mounting frame 109 , a glue spraying mechanism mounting frame 108 and the loading module 105 . Wherein, the workbench 101 is arranged on the top of the control cabinet 104 . The control cabinet 104 is fixed on the lowermost end of the glue spraying device, and the bottom of the control cabinet 104 is provided with a support 112, so that the distance between the control cabinet 104 and the ground is set at a height, which is convenient for controlling the heat dissipation of the electronic equipment in the cabinet 104, and avoiding Moisture on the ground can affect the normal operation of electronic equipment. ...

Embodiment 2

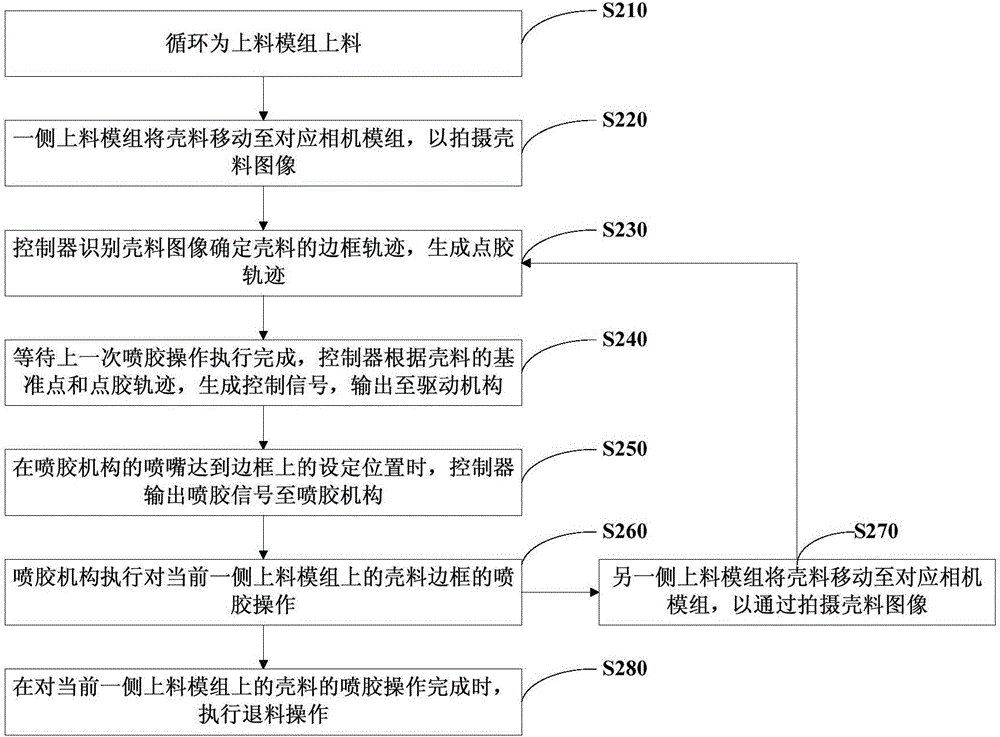

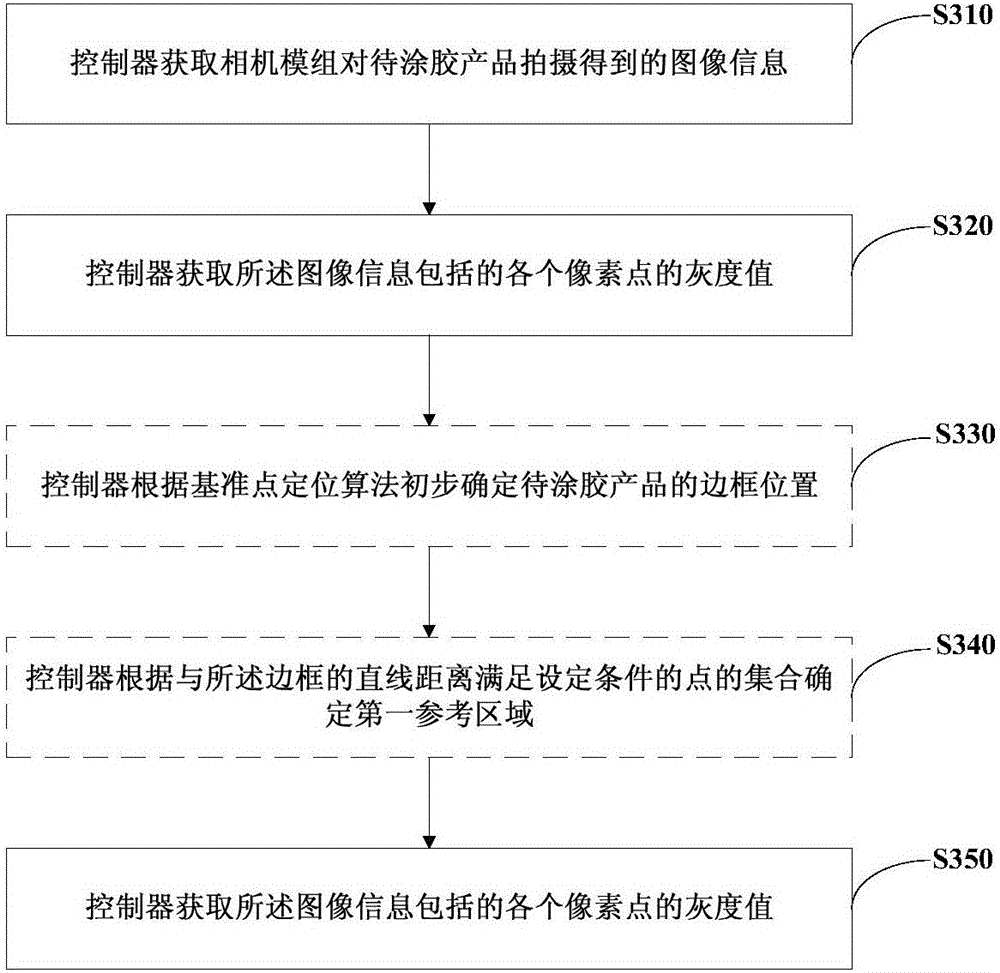

[0067] image 3 It is a flow chart of a method for determining the frame trajectory provided by Embodiment 2 of the present invention. This embodiment is applicable to the case of determining the frame of a narrow frame product. This method can be executed by the glue spraying device in the above embodiment. Specifically Including the following steps:

[0068] Step 310, the controller obtains the image information captured by the camera module on the product to be glued.

[0069] Wherein, the image information includes a plurality of sub-image information about the product to be glued, and the complete image information of the product to be glued is obtained after splicing the sub-image information.

[0070] Exemplarily, the controller acquires the first sub-image and the second sub-image obtained by taking two shots of the product to be glued by the camera module, and splicing the first sub-image and the second sub-image to obtain the corresponding image of the product to be...

Embodiment 3

[0080] Figure 4 It is a flow chart of a method for determining a frame trajectory provided by Embodiment 3 of the present invention. Such as Figure 4 As shown, the method specifically includes the following steps:

[0081] Step 410: Obtain a pre-drawn glue road map corresponding to the product to be glued, and generate a first frame track according to the glue road map.

[0082] The glue road for the glue spraying operation of the product to be glued can be drawn in advance according to the design drawing, using a drawing tool, and saved as a glue road diagram corresponding to the glue sprayed product. When it needs to be used, import the glue road map of the corresponding product to be glued into the glue spraying device, and the first frame track of the product to be glued to be sprayed can be automatically generated in the glue spraying device. Exemplarily, according to the design drawing of the shell material to be glued, the glue road map corresponding to the shell m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com