Drum entanglement cutting-off and removing device for spreading machine

A technology of removal device and leveler, which is applied in the removal of solid waste and metal processing, etc., can solve the problems of poor working environment for workers, ineffective anti-winding measures, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

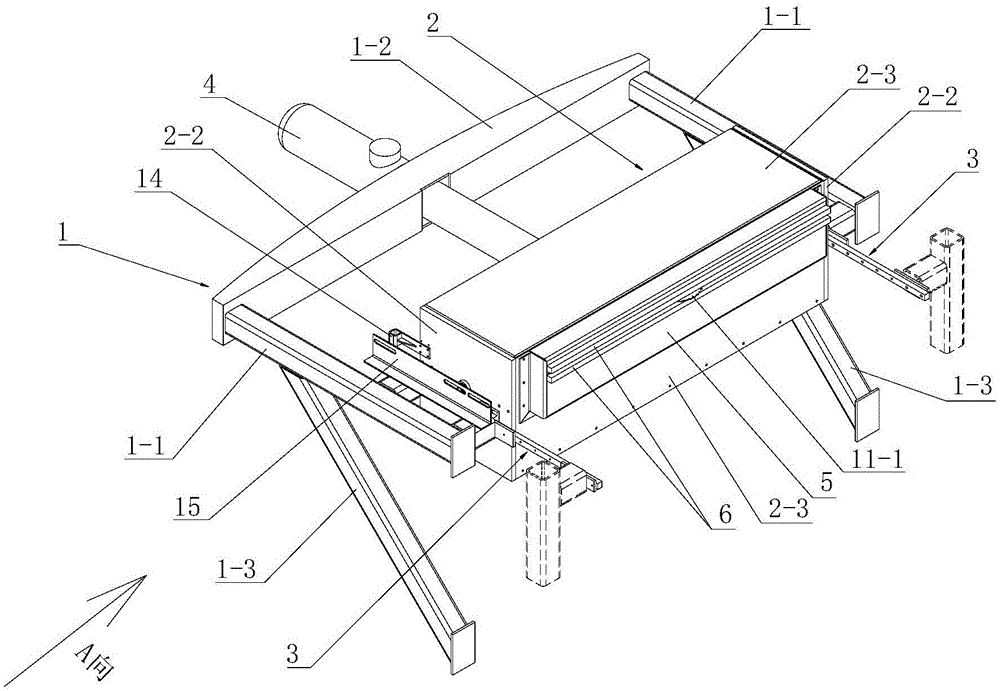

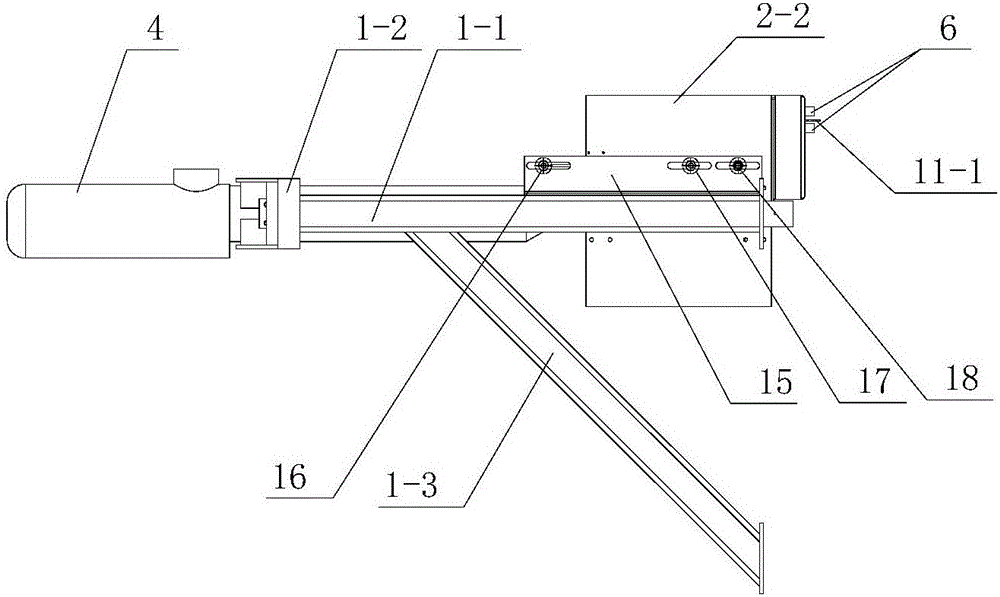

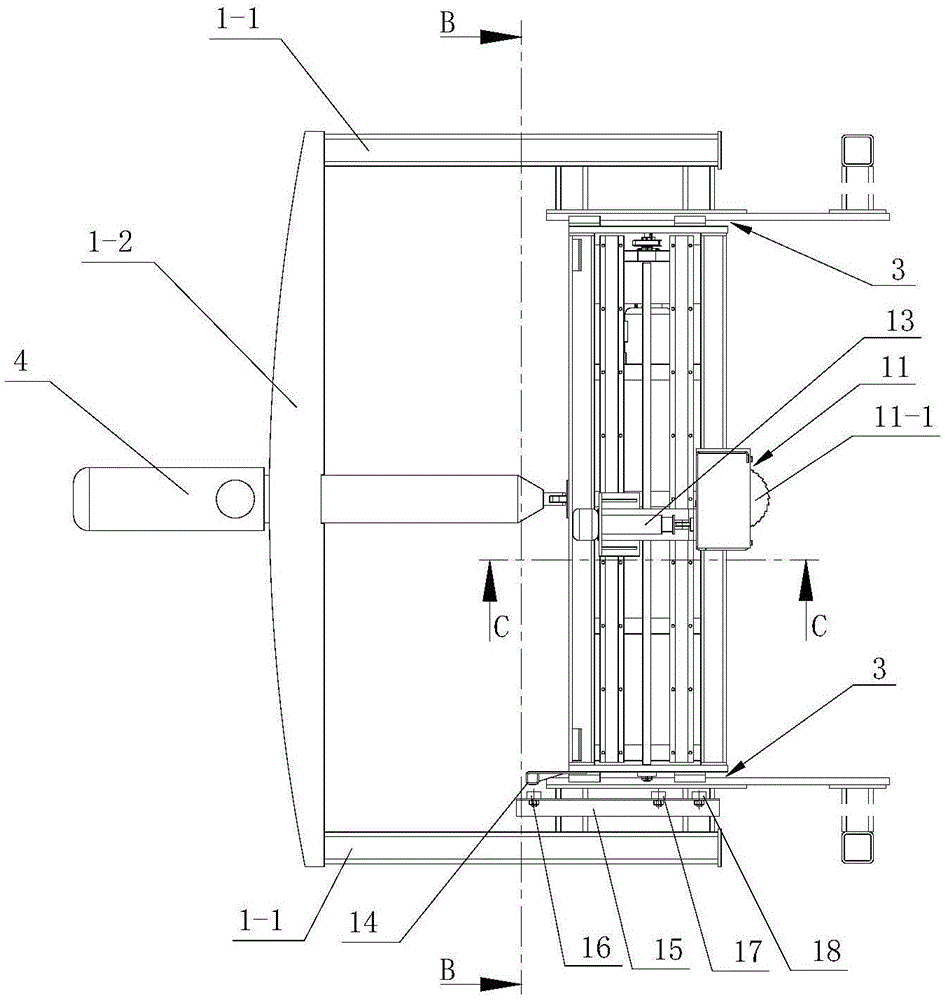

[0022] See Figure 1-6 , used for cutting and clearing the drum windings on the leveler, the main components are:

[0023] Including a support frame body 1, the support frame body is composed of two support arms 1-1 arranged in parallel on the left and right, a beam 1-2 connected to the rear ends of the two support arms, and two beams 1-2 respectively arranged at the lower ends of the two support arms. Diagonal braces are composed of 1-3. The front ends of the two support arms and the front ends of the two diagonal braces are fixedly connected with the frame body of the leveler, so that the support frame body is fixed on one side of the frame body of the leveler, so that The support frame and the frame of the leveler are called an integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com