A drain valve automatic capping device and valve cap assembly method

A technology for drain valve and valve cover, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of manual operation of drain valve capping, low efficiency, and inability to guarantee processing quality, so as to improve the pass rate and consistency. , to ensure accuracy, to avoid the effect of disorganized teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

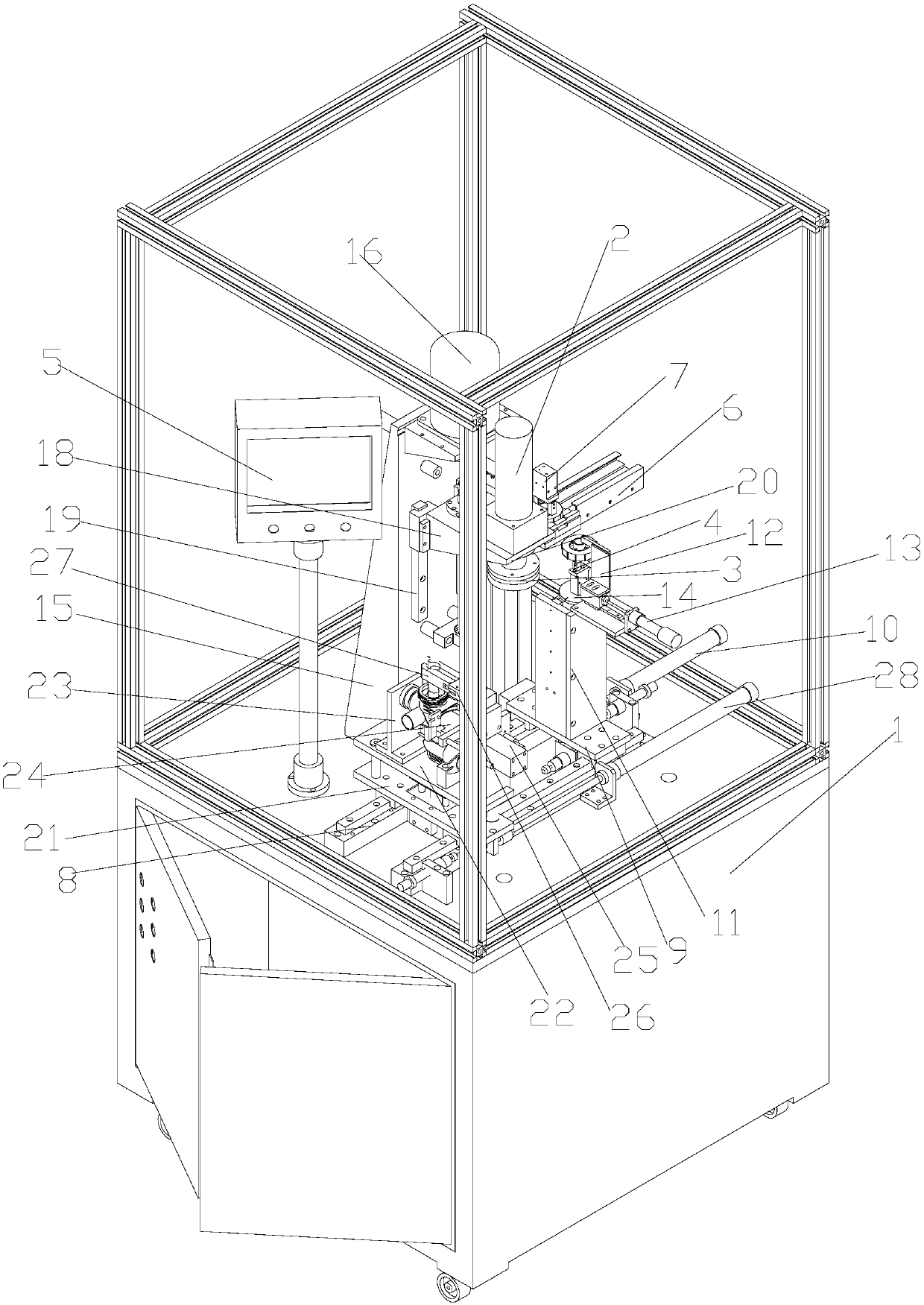

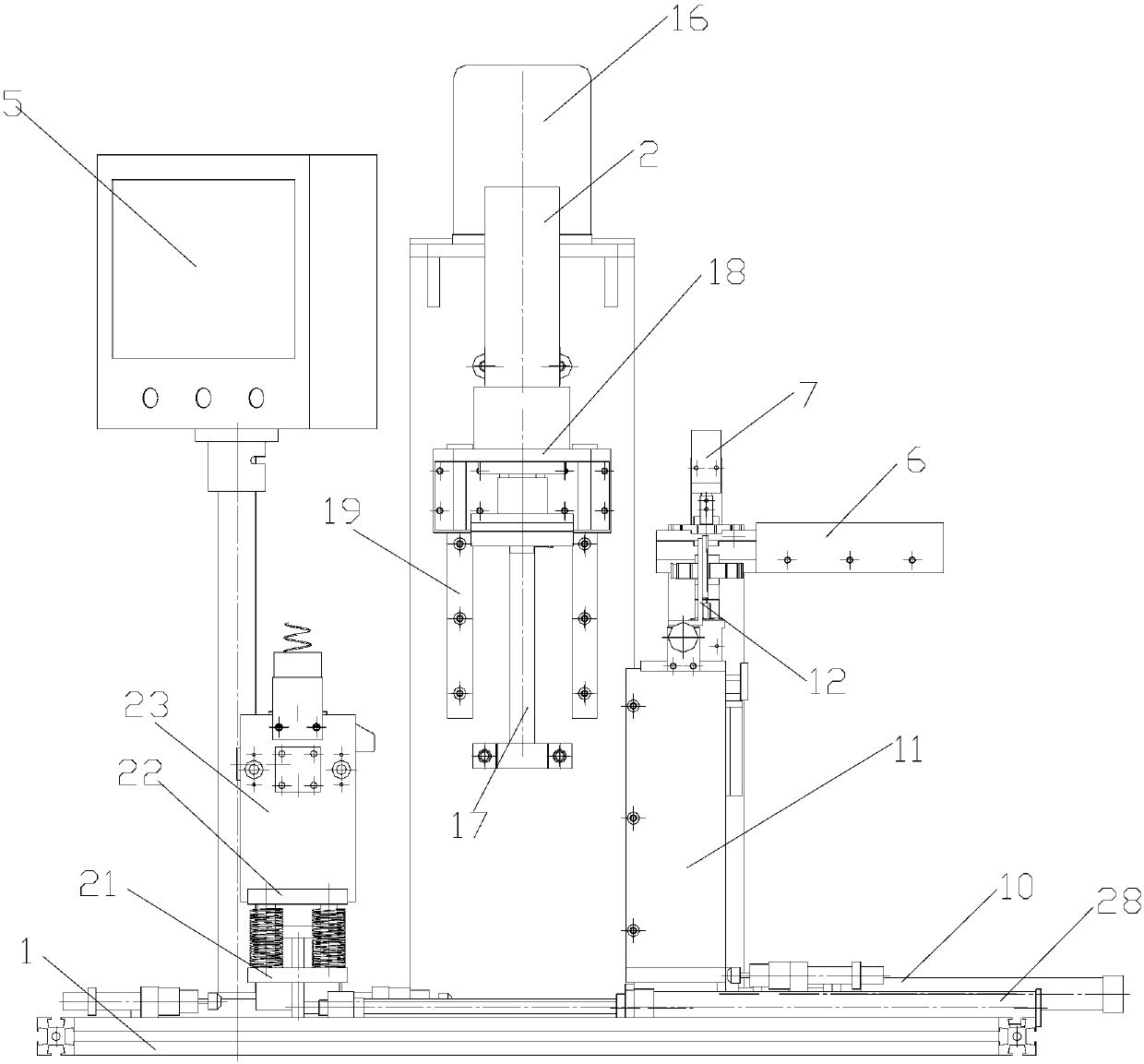

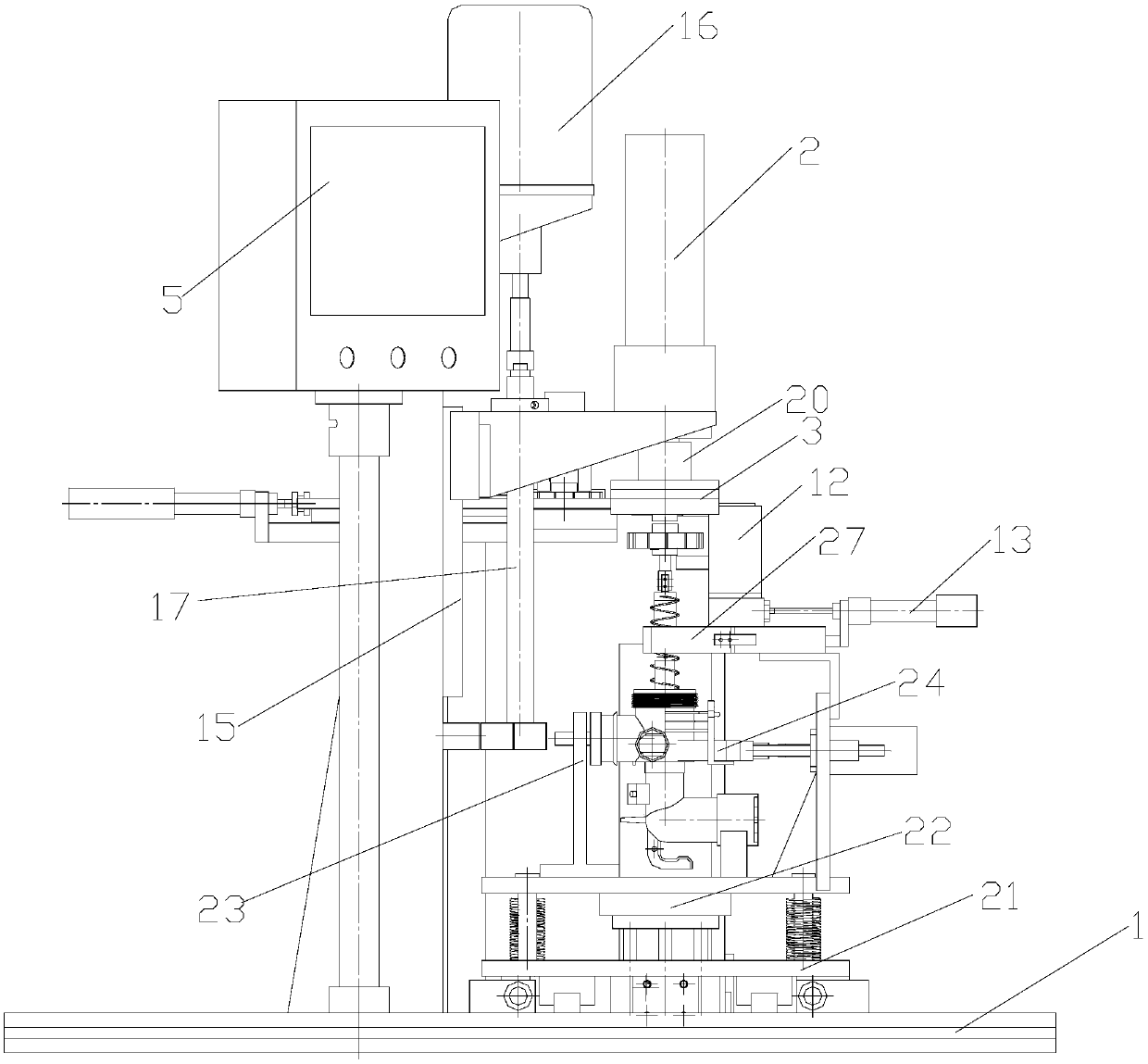

[0028] Examples such as Figures 1 to 3 As shown, an automatic cap screwing device for a drain valve is used for automatic screwing of a valve cover, and a group of ribs arranged in the axial direction are arranged on the side wall of the valve cover. The equipment includes a frame 1, a lifting mechanism arranged on the frame 1, an automatic cap feeding mechanism and a valve body fixed translation mechanism; the lifting mechanism is provided with a cap screwing mechanism that can move up and down, and is also provided with a mechanism to control the action of each mechanism. The controller 5.

[0029] The automatic cap feeding mechanism includes a bonnet conveying track 6, the feed end of the bonnet conveying track 6 can be provided with a vibrating conveying plate, and can also be other conveying structures, so that the bonnet can be automatically transported to the bonnet conveying track 6 , and move forward continuously. Located at the end of the bonnet conveying track 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com