Rotary type workpiece adsorption platform

A rotary and platform technology, applied in the direction of workbench, metal processing machinery parts, manufacturing tools, etc., can solve the problem of easy falling, and achieve the effect of stable adsorption, uniform adsorption force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

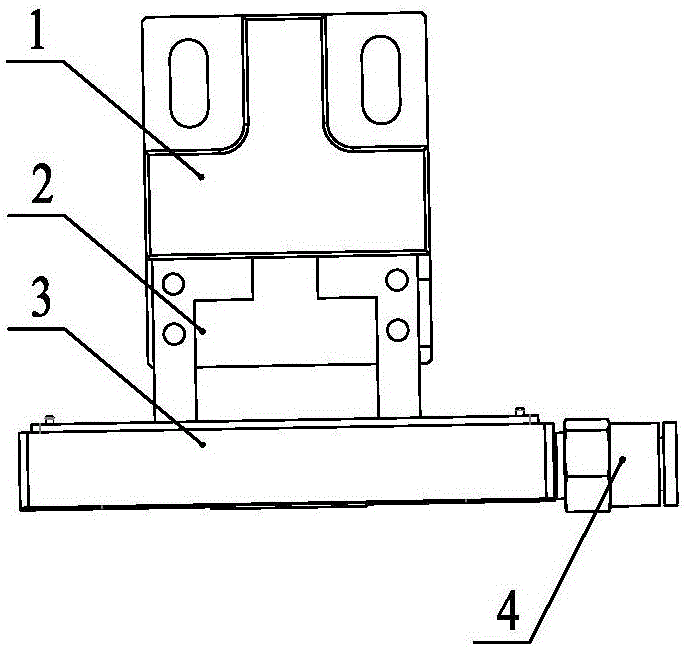

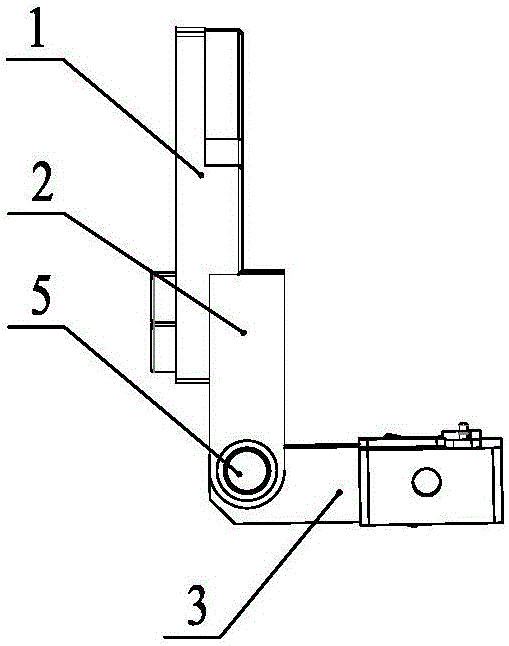

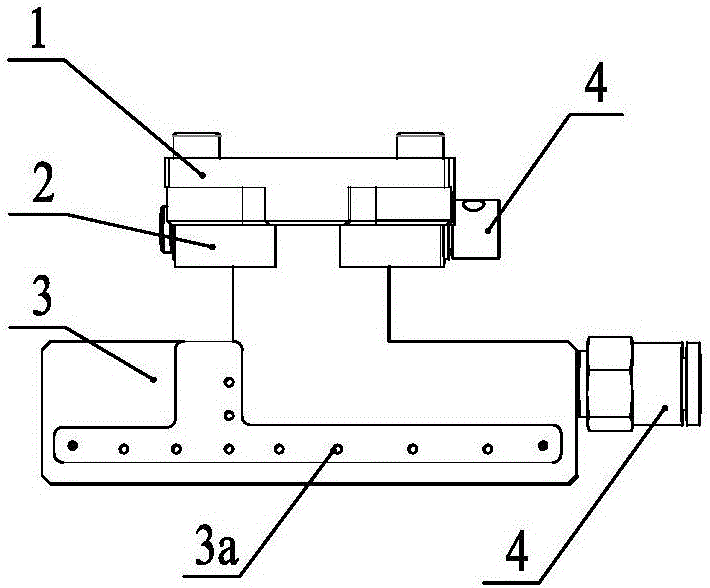

[0011] As shown in the figure: the rotary workpiece adsorption platform in the embodiment is mainly composed of a mounting bracket 1 , a fixed plate 2 , a platform body 3 , a gas pipe joint 4 and a rotating shaft 5 .

[0012] Such as Figure 1~Figure 3 As shown, the rear side of the adsorption platform is pivotally connected to the lower side of the fixed plate 2 through the rotating shaft 5, and the fixed plate 2 is fixedly mounted on the mounting bracket 1; The upper surface of the body 3 is provided with an air hole 3a communicating with the cavity; the platform body 3 is provided with an air suction port communicating with the cavity, the air pipe joint 4 is installed at the air suction port, and the air pipe joint 4 For connecting an external vacuum generator.

[0013] Such as Figure 1~Figure 3 As shown, in order to enable the workpiece to be accuratel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com